Piercing plug device of piercer, piercer and production method of seamless steel tubes

A technology of seamless steel pipe and production method, which is applied in metal rolling, manufacturing tools, mandrels, etc., can solve the problem of uncontrollable defect rate on the inner surface of high-alloy steel pipe, and achieves low equipment modification difficulty, good application effect, and internal The effect of improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, a piercer plug device, a piercer, and a seamless steel pipe production method according to the present invention will be described in detail with reference to exemplary embodiments.

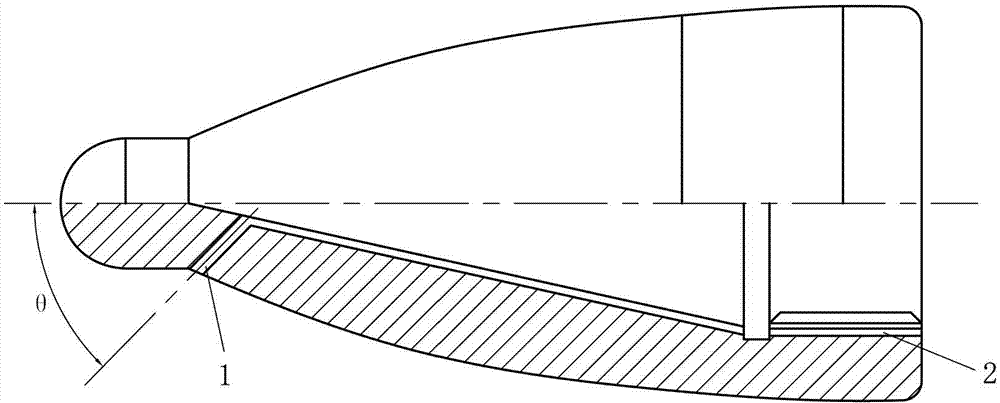

[0021] A plug device for a piercing machine according to an exemplary embodiment of an aspect of the present invention includes a plug and a push rod. An air pipeline is formed inside the plug and the ejector rod, and one or more air outlets communicating with the air pipeline are arranged at the nose of the plug. Preferably, the plurality of air outlet channels are evenly arranged along the circumference of the plug nose, and the number thereof is 2 to 5. Further, the angle between the centerline of the air outlet channel and the centerline of the plug is 30-60°.

[0022] According to another exemplary embodiment of the present invention, the piercer includes the piercer head device with the above-mentioned structure.

[0023] A method for producing a seamless steel pipe ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com