Vertical composite winding process for prepreg tape at expansion section of oversized spray pipe

A technology of oversized size and winding process, which is applied in the direction of household components, household appliances, and other household appliances. It can solve problems such as low product performance, serious polyglue lines, and gullies, so as to ensure stability and effectiveness. Resin reaction Consistency in rate, reduction in number and depth of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

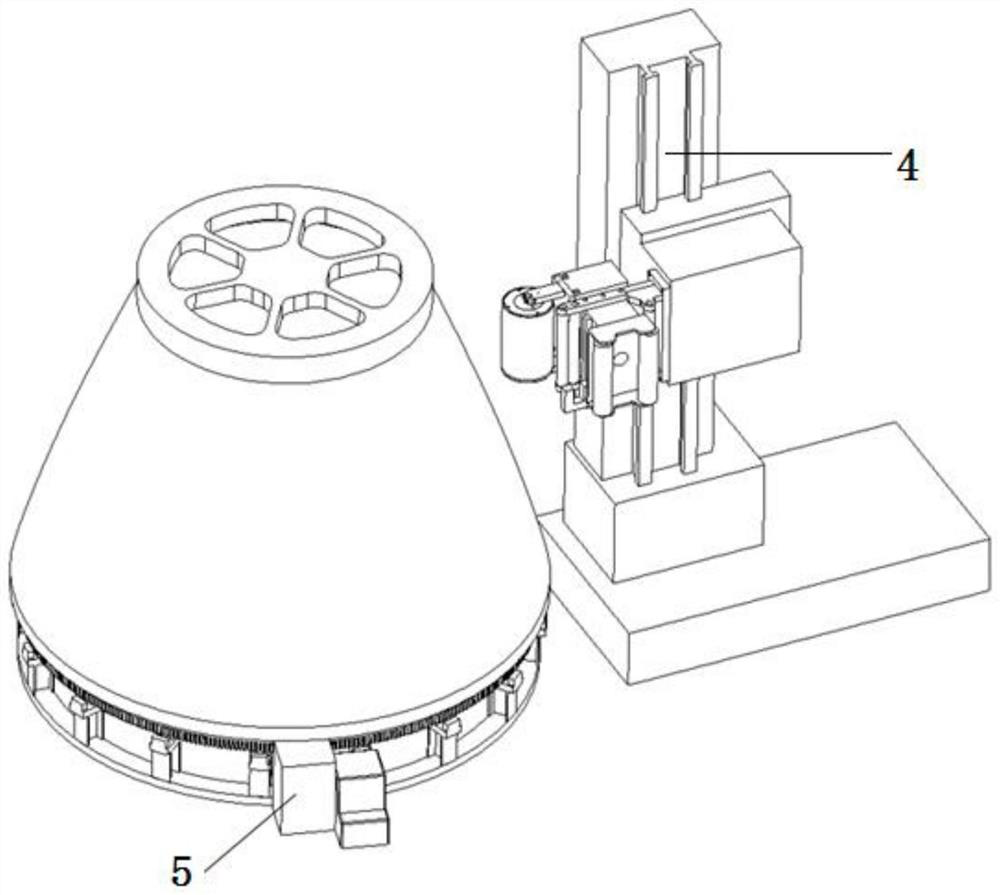

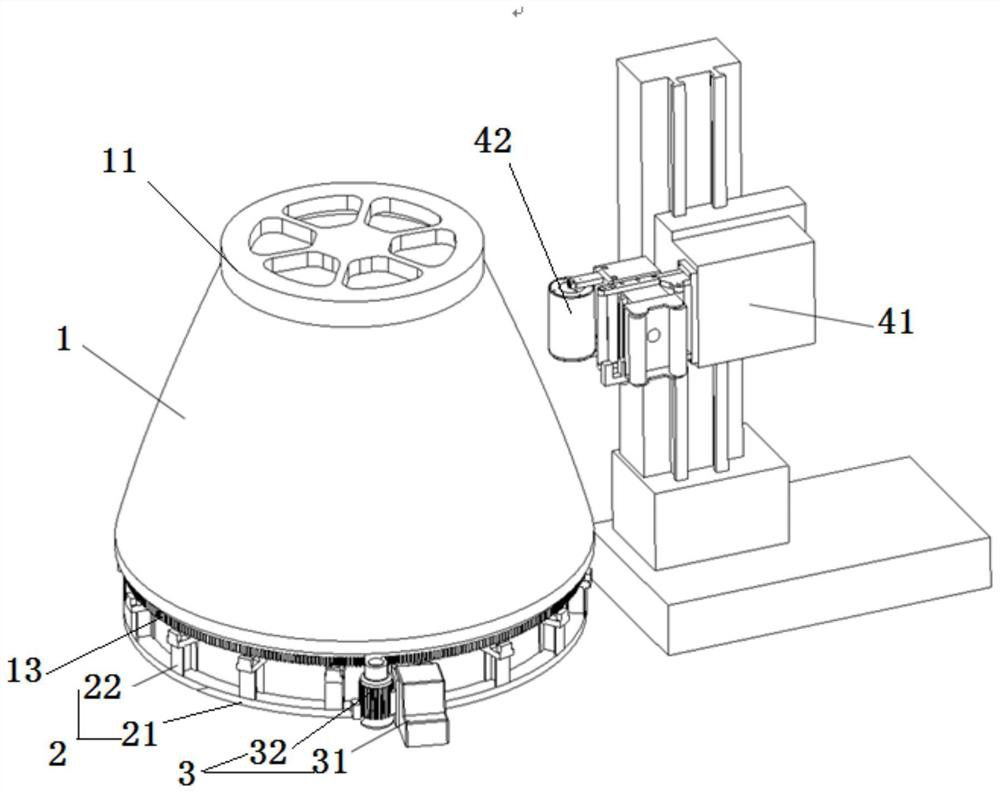

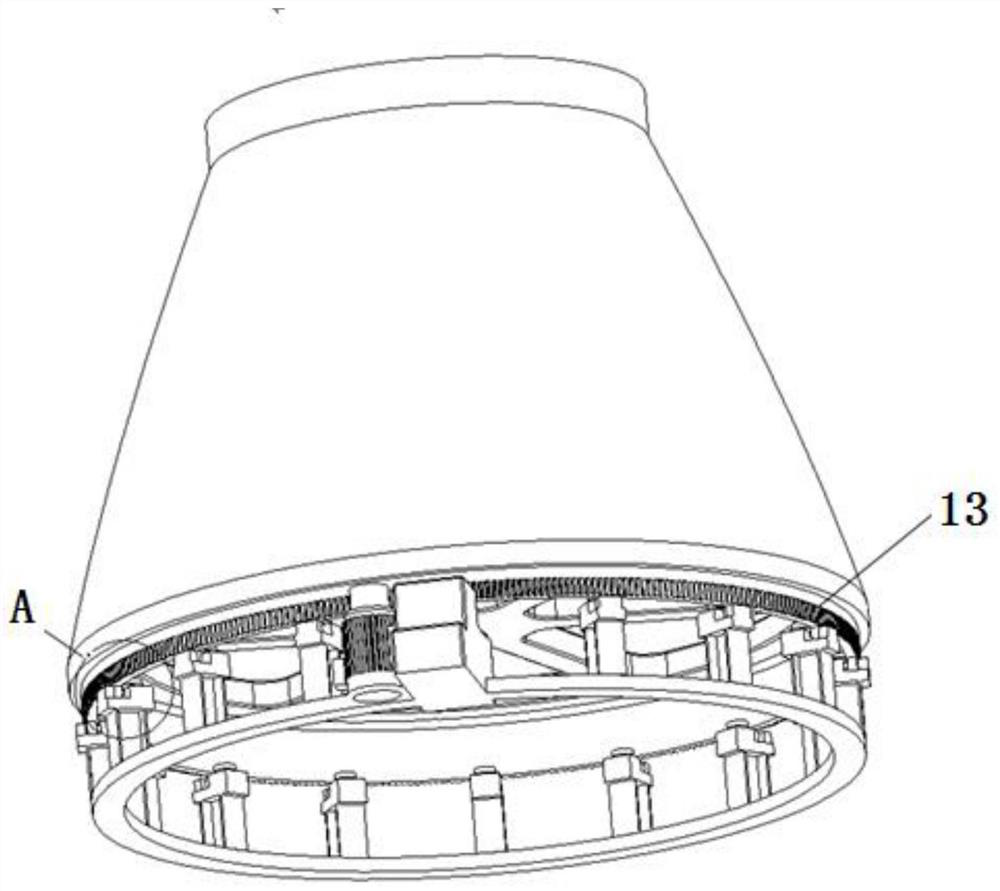

[0055] see figure 1 and figure 2 Shown: a super-large nozzle expansion section prepreg tape vertical composite winding equipment, including expansion section core mold 1, rotating track 2, rotary drive mechanism 3, vertical tape winding mechanism 4, the upper end of the expansion section core mold 1 is provided with The cylindrical winding area 11 can realize the winding molding of prepreg tapes with a width of 20mm-180mm, and the inner and top ends are processed with a reinforcing rib structure 12 (see Figure 5 ), the lower cylindrical surface is circumferentially machined with gear teeth 13 (see image 3 ), the axial section of the expansion section core mold 1 is in the shape of an isosceles trapezoid; the rotating track 2 includes a circular base 21 and a support frame 22 evenly distributed along the circumference of the circular base 21, and the support frame 22 is provided with a gravity support bearing 221 and a circumferential direction Limit bearing 222 (see Fig...

Embodiment 2

[0063] The following will refer to Figure 1-Figure 5 The process of the present invention will be described in detail.

[0064] A vertical composite winding process for prepreg tapes in the expansion section of an oversized nozzle, comprising the following steps:

[0065] Step S1: vertically lift the expansion section core mold 1, and slowly drop it onto the gravity support bearing 221 to ensure that the gear teeth 13 mesh with the drive gear 32, and ensure that the inner cylindrical surface at the bottom of the expansion section core mold 1 cooperates with the circumferential limit bearing 222 to meet the expansion requirements. The segment core mold 1 rotates around the axis on the rotary drive mechanism 3;

[0066] Step S2: adjust the position of the winding trolley 41 of the vertical tape winding mechanism 4 to meet the requirements of the winding station;

[0067] Step S3: Thread the carbon cloth / barium phenolic dry wrapping tape into the vertical tape winding mechanis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com