Process for thin-wall hot-rolled seamless steel tube in double mandrel two-roll rotary rolling production

A technology of seamless steel pipes and double mandrel rods, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of seamless steel pipe production and manufacturing capacity, low quality, irregular radial structure cracking and deformation, and production efficiency Low-level problems, to achieve the effect of improving production efficiency and quality, prolonging wear life, and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

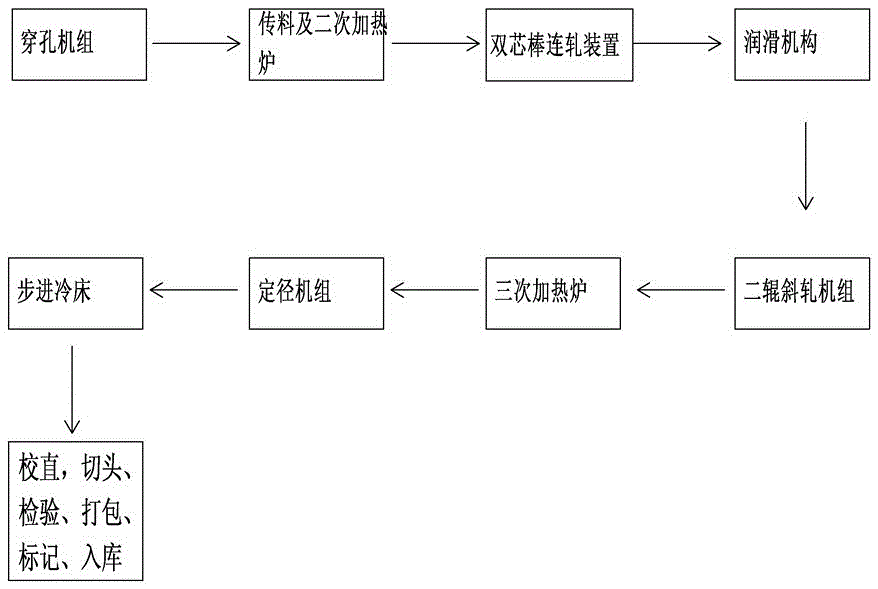

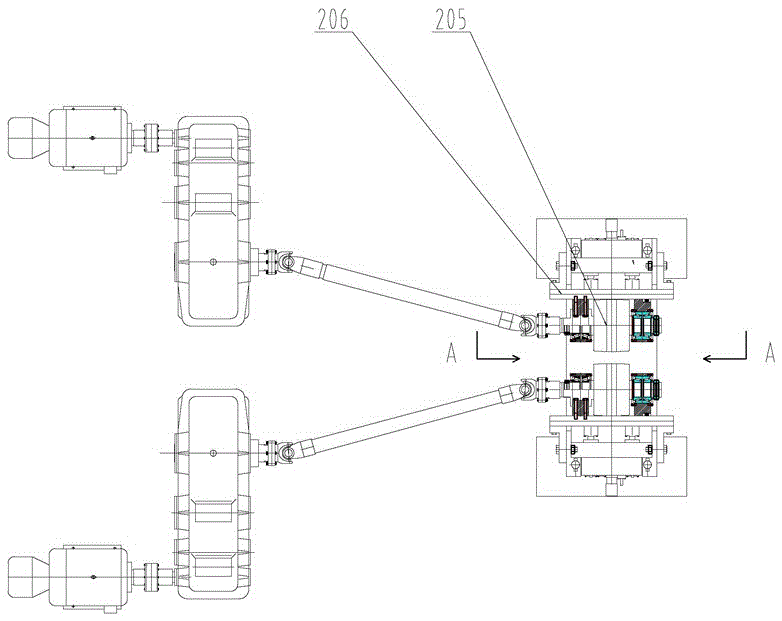

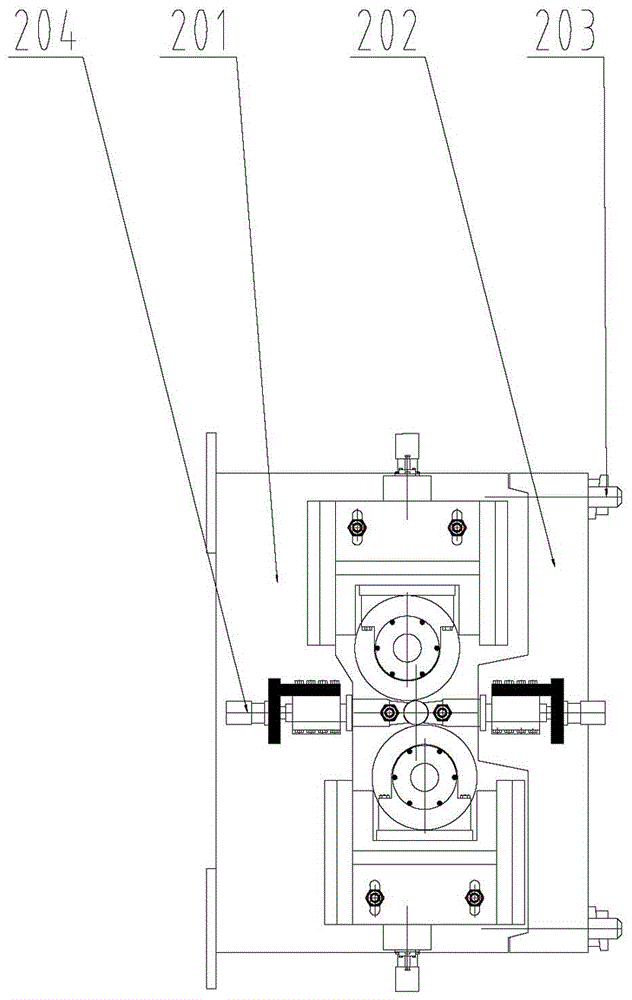

[0045] Such as Figure 1 to Figure 4 Shown, a kind of technology of thin-walled hot-rolled seamless steel pipe in the production of double-mandrel two-roll cross-rolling, comprises the following steps:

[0046] Step 1), heating, heating the tube billet to above 1200°C in the tube billet heating furnace;

[0047] Step 2), piercing, the heated tube blank is pierced by the piercing unit to make a capillary tube;

[0048] Step 3), material transfer and secondary heating, the capillary tube made by the piercing unit is sent into the secondary heating furnace through the material transfer mechanism, and advances at a speed of 0.5m / s-1.5m / s in the secondary heating furnace. Carry out secondary heating and soaking, and the temperature after secondary heating is 900°C; the secondary heating furnace is a long straight furnace, which adopts gas heating or electric heating, and there are multiple sets of V-shaped straight lines in the secondary heating furnace. wheel, and powered by mot...

Embodiment 2

[0058] Such as Figure 1 to Figure 4 Shown, a kind of technology of thin-walled hot-rolled seamless steel pipe in the production of double-mandrel two-roll cross-rolling, comprises the following steps:

[0059] Step 1), heating, heating the tube billet to above 1200°C in the tube billet heating furnace;

[0060] Step 2), piercing, the heated tube blank is pierced by the piercing unit to make a capillary tube;

[0061] Step 3), material transfer and secondary heating, the capillary tube made by the piercing unit is sent into the secondary heating furnace through the material transfer mechanism, and advances in the secondary heating furnace at a speed of 0.5m-1.5m per second for the secondary heating. Secondary heating and soaking, the temperature of the secondary heating is heated to 950°C. The secondary heating furnace is a long straight furnace, which adopts gas heating or electric heating. There are multiple sets of V-shaped wheels arranged in a straight line in the seconda...

Embodiment 3

[0071] Such as Figure 1 to Figure 4 Shown, a kind of technology of thin-walled hot-rolled seamless steel pipe in the production of double-mandrel two-roll cross-rolling, comprises the following steps:

[0072] Step 1), heating, heating the tube billet to above 1200°C in the tube billet heating furnace;

[0073] Step 2), piercing, the heated tube blank is pierced by the piercing unit to make a capillary tube;

[0074] Step 3), material transfer and secondary heating, the capillary tube made by the piercing unit is sent into the secondary heating furnace through the material transfer mechanism, and advances in the secondary heating furnace at a speed of 0.5m-1.5m per second for the secondary heating. Secondary heating and soaking, the temperature of the secondary heating is heated to 1000°C. The secondary heating furnace is a long straight furnace, which adopts gas heating or electric heating. There are multiple sets of V-shaped wheels arranged in a straight line in the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com