Construction machine for casting underdrain on site by cement

A technology of construction equipment and cement, which is applied to the field of cast-in-place construction equipment of farmland irrigation and drainage culverts, can solve the problems of insecurity, easy damage, low efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

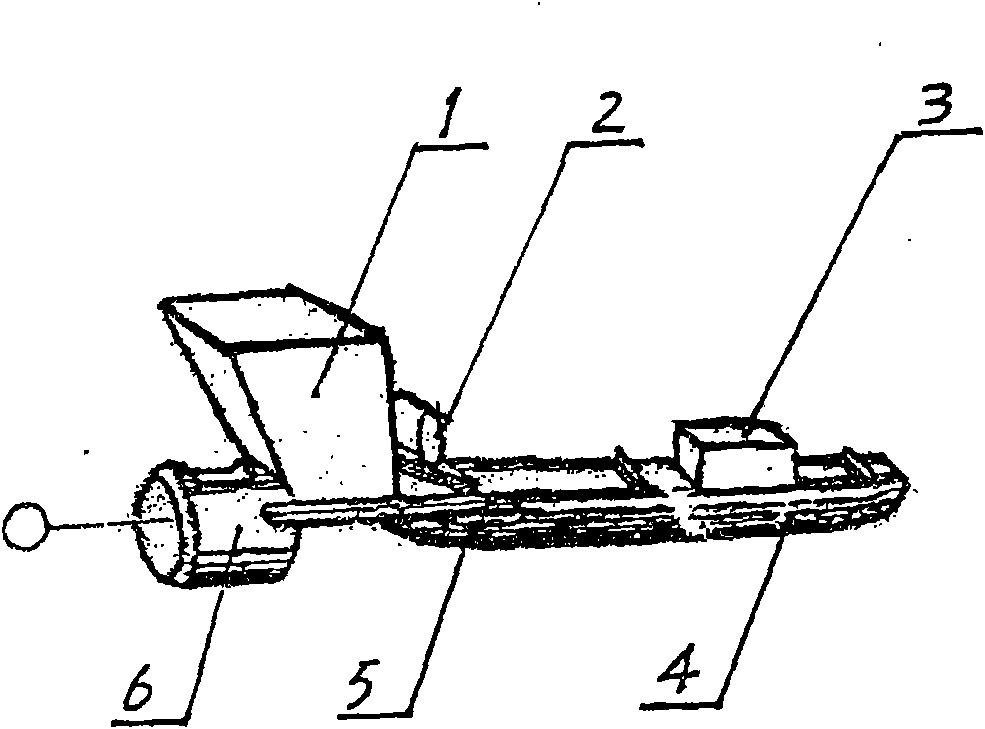

[0011] figure 1 Shown is the schematic diagram of the lower half-pipe forming slipform. When pouring the lower half-pipe, the excavated soil canal wall must be smoothed and the residual soil in the groove must be removed, and then the lower half-pipe forming slipform shall be erected in the soil groove Above, the gap between the sliding form and the wall of the soil tank should be equal to the wall thickness of the cement pipe. Put the cement concrete into the lower half pipe hopper 1, and the front traction mechanism pulls the lower half pipe forming sliding form forward through the guide section 6, and the cement concrete continues to move forward. To fill the cavity of the soil canal, there is a vibrator 2 on the upper side of the lower half-pipe vibration forming section 5 to vibrate the cement compactly, and there is a counterweight 3 on the lower half-pipe smoothing section 4, and their function is to compact the cement. The cement is troweled, so that the sliding form k...

Embodiment 2

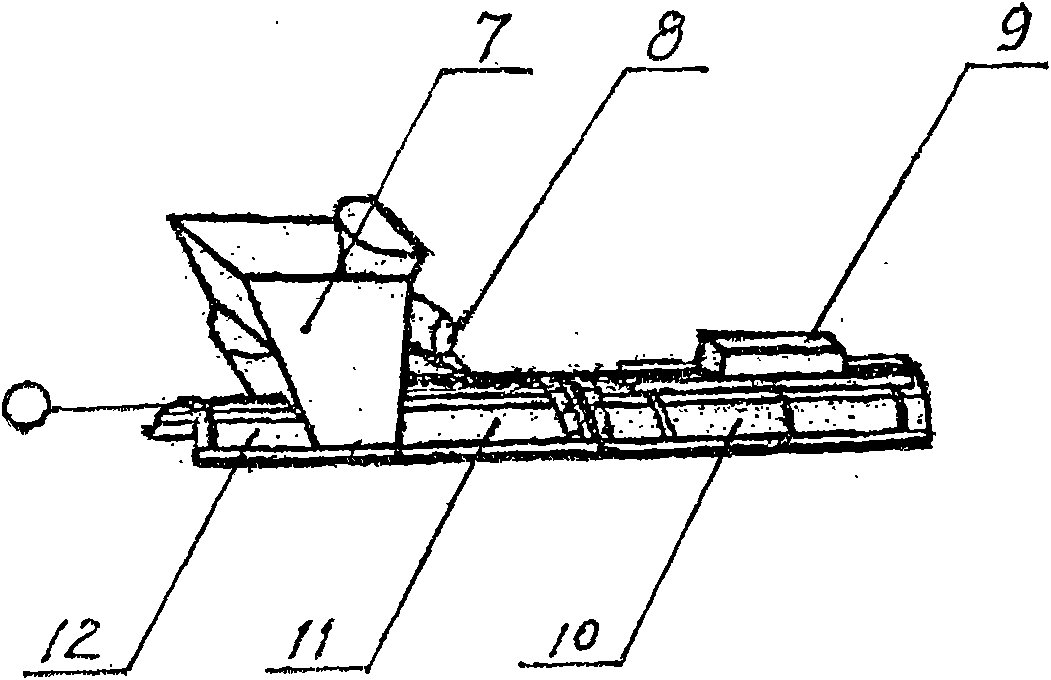

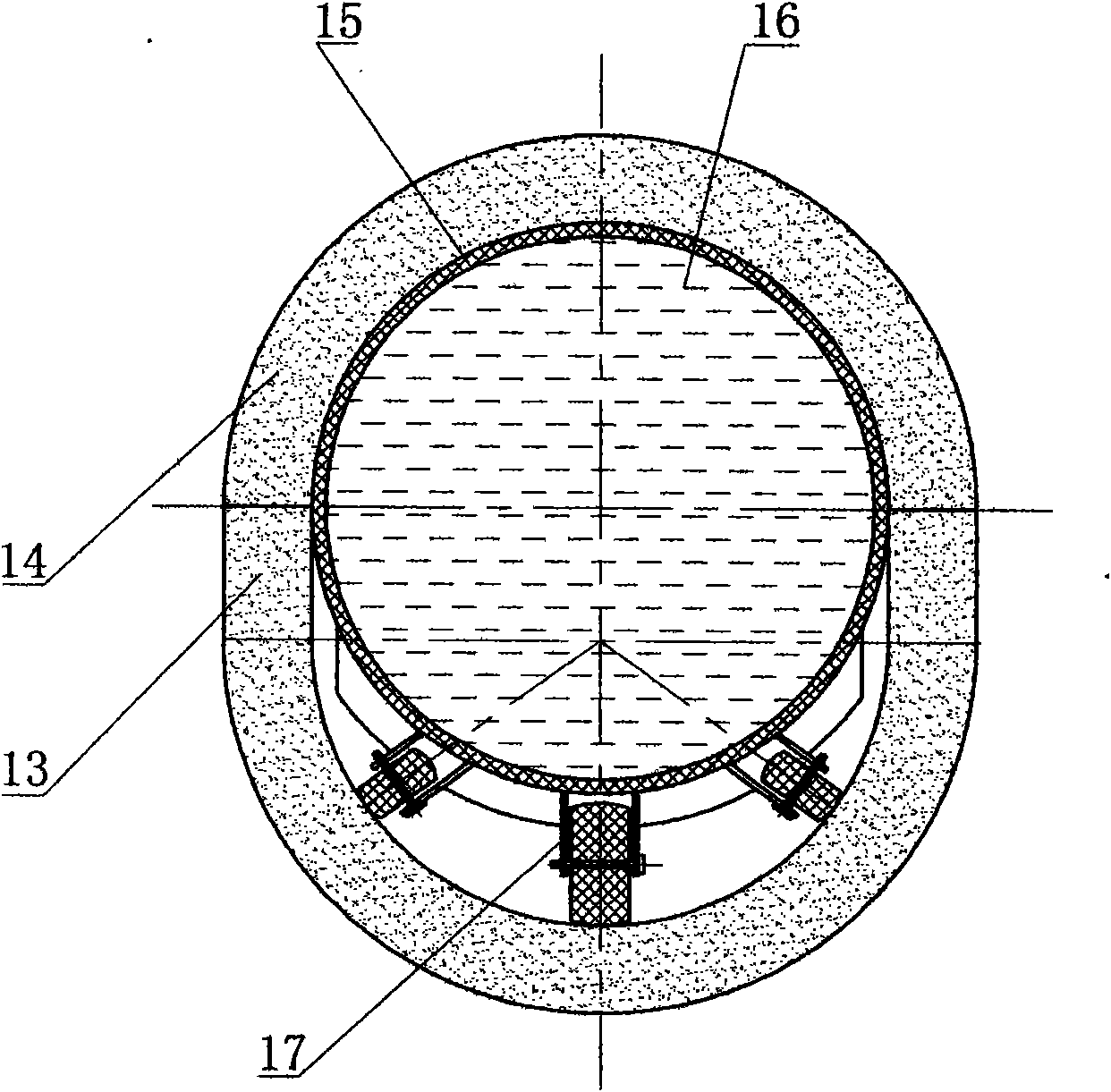

[0013] Such as image 3 As shown, after the lower half pipe is poured and solidified, several small sports cars 17 are laid in the lower half pipe. The length of each small sports car is 2 meters. The number of small sports cars is determined according to the length of the water bag. The small sports cars are connected by wire ropes. , Water bladder 15 is laid on the small sports car. When the pressure water 16 was full of the water bag 15, the pouring construction of the upper half pipe could be carried out. In order to prevent the cement from sticking to the water bag 15, a layer of plastic film was spread on the surface of the upper half of the water bag 15. Set up the upper half pipe forming slide form on the lower half pipe 13 and the water bag 15, the gap between the upper half pipe sliding form inner cavity and the water bag 15 should be equal to the wall thickness of the upper half pipe 14 of cement, and add the upper half pipe feeding hopper 7 For cement concrete, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com