Preparation method of welded stainless steel pipe for boiler

A technology for stainless steel tubes and boilers, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of lower product qualification rate, difficult quality control, scratches on the inner wall of the tube, etc., to improve the qualification rate, improve the processing process, The effect of improving the quality of the outer surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

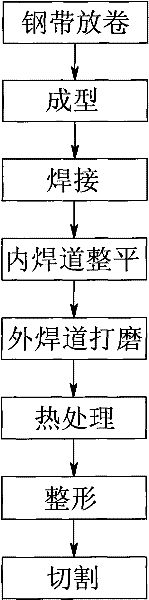

[0029] Processing boiler tubes with an outer diameter of 76.2mm and a wall thickness of 1.65mm

[0030] (1) Steel strip unwinding: Select a stainless steel strip coil with a width of 240mm and a thickness of 1.65mm, put it on the uncoiler and uncoil it, and then enter the welding pipe making unit.

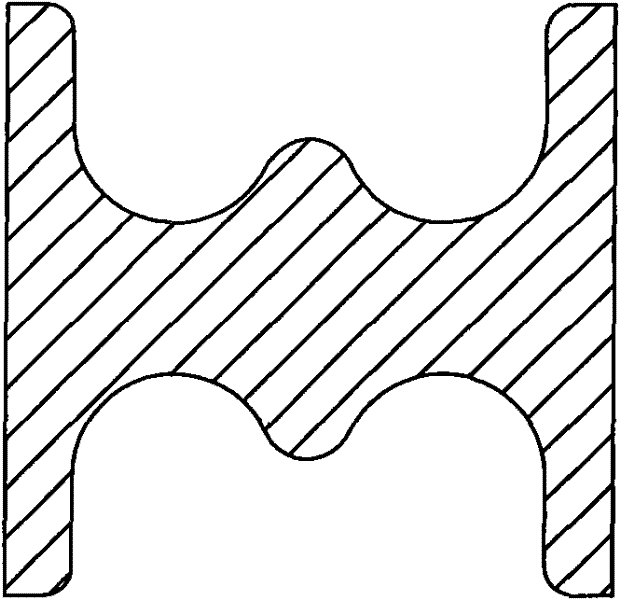

[0031] (2) Forming: Utilize the W-forming forming die to form a tubular shape through the forming section, and reserve a straight line weld.

[0032] (3) Welding: The welding torch current is controlled at 200A for continuous welding into tubes.

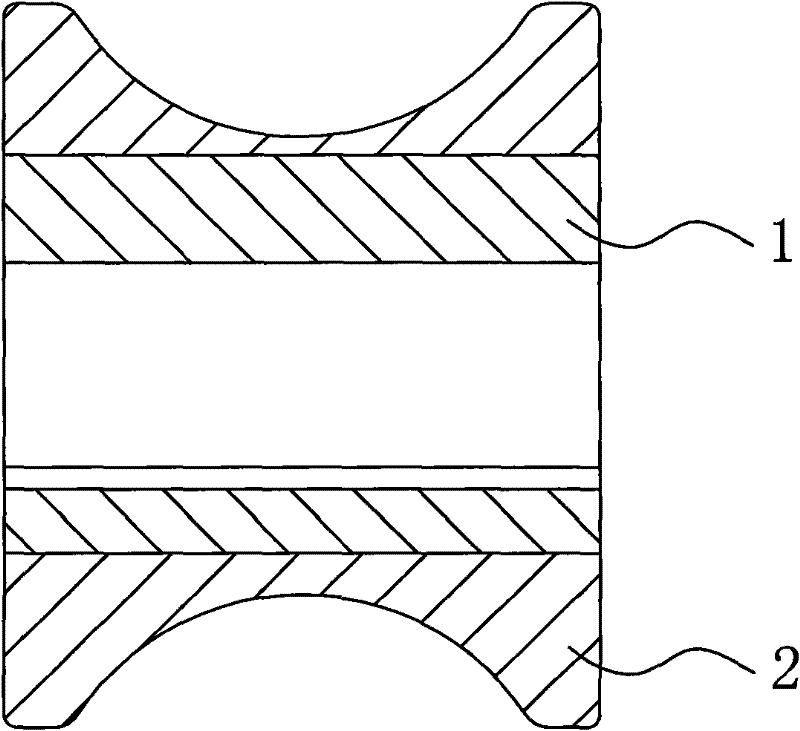

[0033] (4) Inner bead leveling: Use a fixed inner die to scrape the inner bead level and smooth.

[0034] (5) Grinding of the outer weld bead: Use an automatic grinding device to grind the outer weld bead flat and smooth.

[0035] (6) Heat treatment: in an inert gas environment, heat treatment at a temperature of 1050-1150°C and then rapidly cool.

[0036] (7) Shaping: rounding and straightening of welded stainless steel pipes to meet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com