Hole-enlarging deforming device and method for metal pipe fitting

A technology of metal pipe fittings and deformation devices, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems affecting the dimensional accuracy of metal pipe fittings, scratches on metal pipe fittings, easy damage to molds, etc., and improve the quality of the inner surface , Avoid direct friction, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

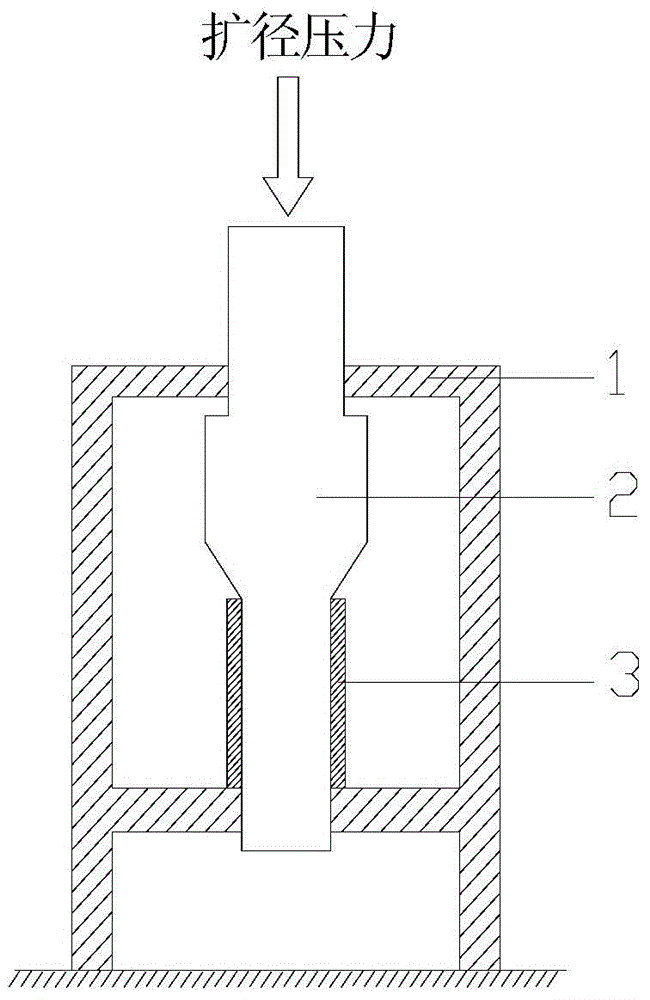

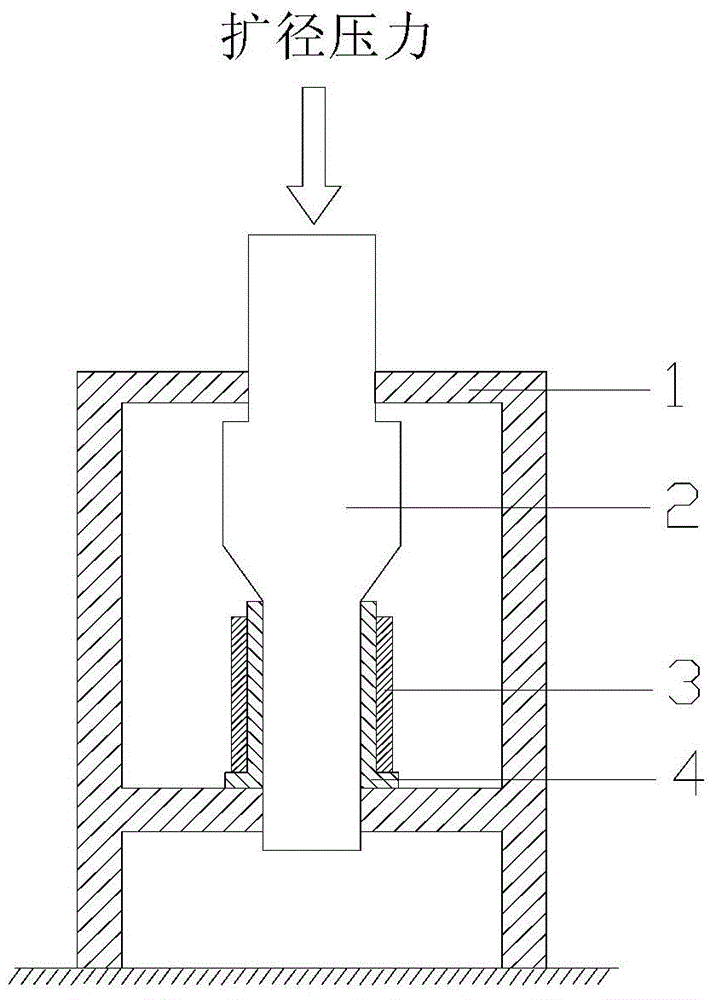

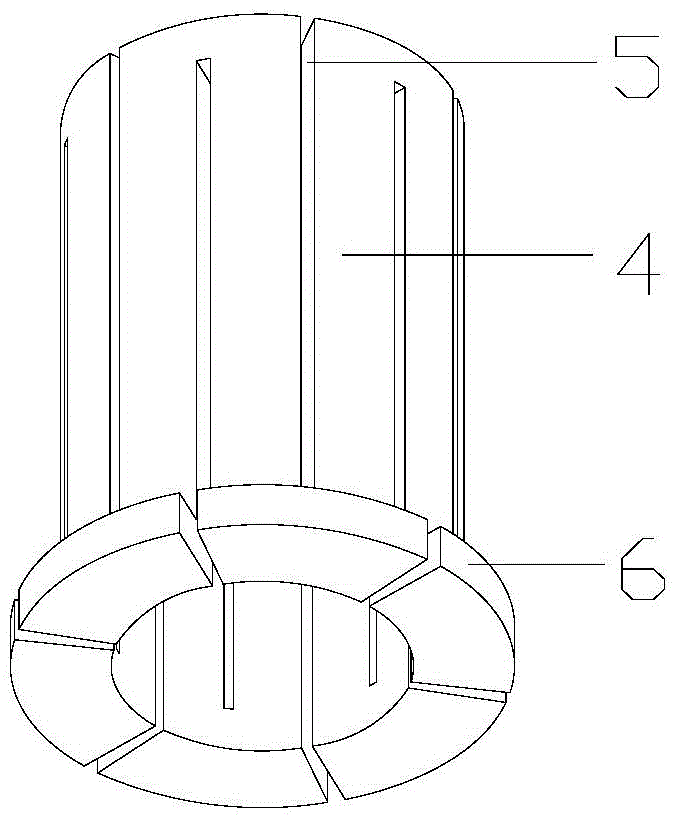

[0023] Such as figure 2 As shown, it is a schematic diagram of a diameter-expanding deformation device for a metal pipe fitting of the present invention. Wherein 1 is the expansion support, 2 is the expansion die, 3 is the metal pipe fitting, and 4 is the elastic mold cover. The expanding die 2 is processed by GCr15 die steel, the hardness is greater than HRC55, and the size of the sizing band is 8.98mm. The metal pipe fitting 3 is a TA1 titanium alloy pipe with an inner diameter of 9.70mm and an outer diameter of 12.10mm. The elastic mold cover 4 is processed by 60Si2MnA steel with good elasticity and rigidity. The inner diameter of the elastic mold cover 4 is 8.70mm, and the outer diameter is 9.90mm. The upper and lower ends of the elastic mold cover 4 are processed with symmetrical non-penetrating concave There are 6 slots, and the slot width is 0.50mm.

[0024] The expansion deformation process of the TA1 titanium alloy pipe fitting of the present invention is as follo...

Embodiment 2

[0029] refer to figure 2 Diameter expansion deformation method of metal pipe fittings shown. The expanding die 2 is processed by Cr12MoV die steel, the hardness is greater than HRC55, and the size of the sizing band is 17.67mm. The metal pipe fitting 3 is a Ni47Ti44Nb9 memory alloy pipe with an inner diameter of 17.95mm and an outer diameter of 23.00mm. The elastic die set 4 is processed by 60Si2MnA steel. The inner diameter of the elastic die set 4 is 15.40mm, and the outer diameter is 18.55mm. The upper and lower ends of the elastic die set 4 are each processed with 5 symmetrical non-penetrating grooves, and the groove width is 0.50mm. .

[0030] The Ni47Ti44Nb9 memory alloy pipe fitting diameter expansion deformation process of the present invention is as follows:

[0031] (1) The radial diameter expansion deformation of the designed Ni47Ti44Nb9 memory alloy pipe fitting is 16% (inner diameter deformation).

[0032] (2) The elastic mold cover 4 is installed in the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com