Pipe pulling and drawing lubricating device and pipe pulling and drawing machining method

A pipe drawing and lubricating device technology, which is applied in the direction of quantitative devices, lubricating parts, engine lubrication, etc., can solve problems such as uneven addition of lubricating oil, low production efficiency, lack of lubricating oil, etc., and achieve good automatic control effect, Effect of improving inner surface quality and improving lubrication conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

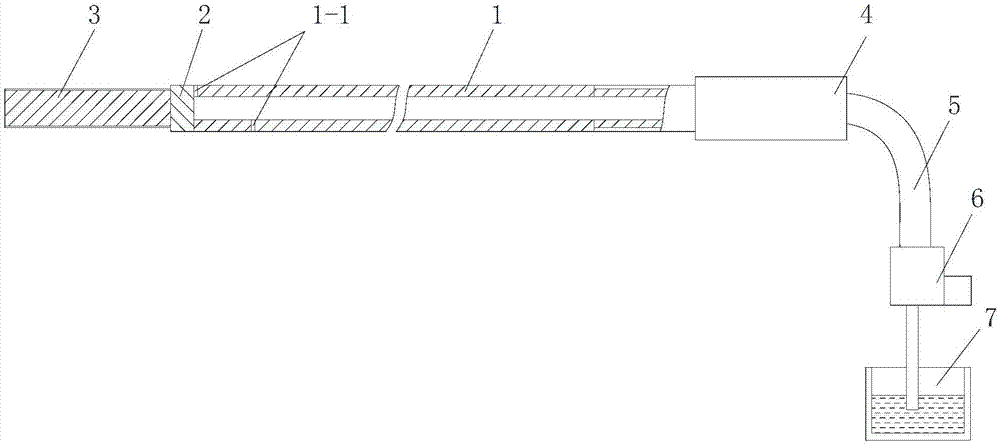

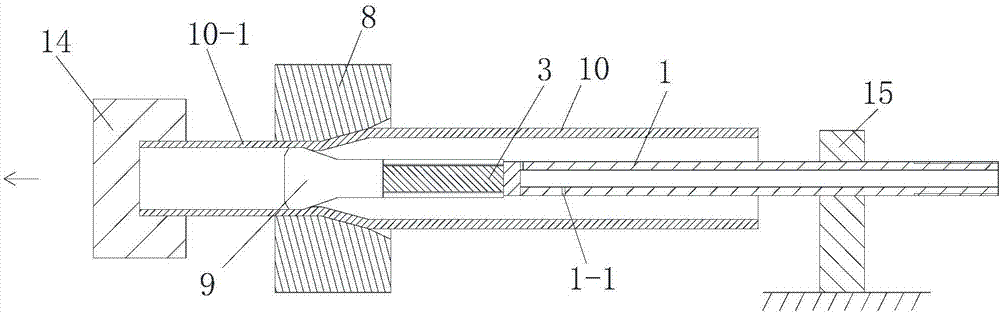

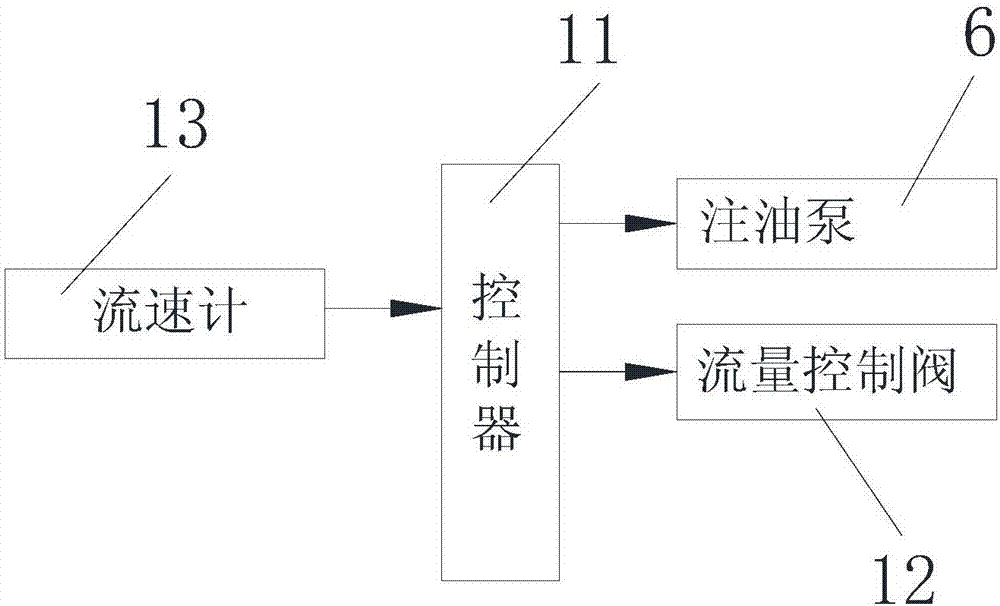

[0048] Such as figure 1 , figure 2 and image 3 As shown, a lubricating device for pipe drawing provided by the present invention includes an oil supply mechanism arranged on a chain broaching machine and a lubricating pipe connected to the oil supply mechanism, and the oil supply mechanism includes an oil tank for holding lubricating oil 7. The oil injection pipe 5 connected to the lubrication pipe and the oil injection pump 6 connected between the oil tank 7 and the oil injection pipe 5. The lubrication pipe is composed of a straight steel pipe 1, a sealing plate 2 arranged at one end of the straight steel pipe 1 and The connecting rod 3 installed on the end face of the sealing plate 2 and used to connect with the drawing core 9 is composed of the straight steel pipe 1 composed of an oil injection section, a clamping section and a connecting section, and the oil injection section is close to a part of the sealing plate 2 On the side, the pipe wall of the oil injection sec...

Embodiment 2

[0063] In this embodiment, the pipe drawing processing method includes the following steps:

[0064] Step 1. Preparation of the tube blank to be drawn:

[0065] Step 101, preparation of raw material tube;

[0066] Step 102, the pretreatment of the raw material tube blank includes the following steps:

[0067] Step 1021, pretreatment of the inner surface of the raw tube blank: using a honing machine to grind the inner surface of the raw tube blank so that the surface roughness of the inner surface of the raw tube blank is 1.6 μm;

[0068] Step 1022, pretreatment of the outer surface of the raw material tube blank: first, seal the openings at both ends of the raw material tube blank with rubber plugs; then, use a coreless grinder to grind the outer surface of the raw material tube blank; then, use an abrasive belt to polish Machine polishing the outer surface of the raw tube blank, so that the surface roughness of the outer surface of the raw tube blank is 0.8 μm;

[0069] St...

Embodiment 3

[0092] In this embodiment, the difference from embodiment 2 is:

[0093] In step 1, the outer diameter of the raw tube blank is 15mm, and the wall thickness of the raw tube blank is 3mm; the surface roughness of the inner surface of the tube blank 10 to be drawn in step a is 1.6um; the outer surface of the tube blank 10 to be drawn in step b is The surface roughness is 0.8um; the length of the elongated section 10-1 is 150mm in the step 103; the cone angle of the frustum-shaped hole described in the step 2 is 27 °; the core head of the drawing core 9 described in the step 3 The gap between the outer surface of the end and the inner surface of the circular tube to be drawn 10 in step 2 is 0.03 mm; is 15mm / s; in step 4, the pipe blank 10 to be drawn is reduced in diameter and wall to form a drawn pipe with an outer diameter of 12mm and a wall thickness of 2.9mm; the set value of the lubricating oil flow rate is 8mm 3 / s.

[0094] In this embodiment, the remaining steps and pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com