Multilayer stage heat protection material and preparing method thereof

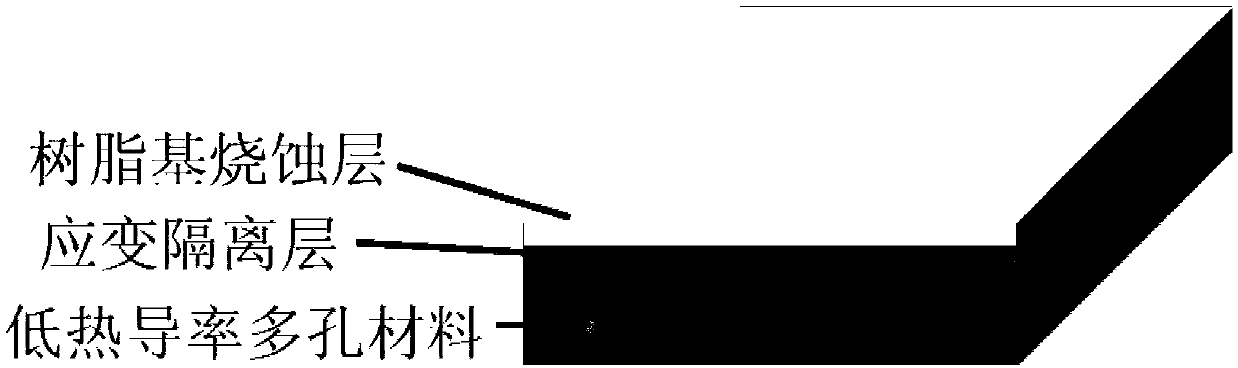

A thermal protection material, multi-level technology, applied in the direction of weight reduction, fuselage insulation, etc., can solve the problems of cracking and delamination of the inner and outer layers of the thermal protection material, affecting the flight use of the aircraft, and large differences in thermal expansion coefficients, so as to prevent collapse. Failure, guaranteeing the effect of anti-scour and thermal insulation, guaranteeing the effect of bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] According to another embodiment, there is also provided a method for preparing the above-mentioned multi-level thermal protection material, which includes the following steps:

[0050] Step 1, forming the inner layer, including:

[0051] Lay a chopped fiber mesh tire with a set number of layers in the mold and perform needle punching to obtain a fiber reinforcement;

[0052] Prepare the polymerized monomer or low-molecular-weight polymer of the resin in the inner layer with an appropriate amount of solvent mixture to prepare a solution;

[0053] Inject the solution into the fiber reinforcement, so that the fiber reinforcement is fully infiltrated with the solution; then solidify at the resin curing temperature;

[0054] Step 2, forming the strain isolation layer, including:

[0055] Coating a certain thickness of room temperature vulcanizable rubber adhesive on the surface of the inner layer, and vulcanizing and setting the rubber adhesive at room temperature;

[005...

Embodiment 1

[0064] The reinforced body of porous material with low thermal conductivity has a density of 0.12g / cm 3 High-silica fiber felt with a size of 300×300×20mm; the resin matrix is made of polysiloxane-modified phenolic resin with a viscosity of 100cP and a gel time of 100°C / 2min. The RTM molding process is used for molding and curing. The resin curing temperature is 120℃, the curing time is 12 hours, and a low-density heat insulation layer is formed after curing. On the surface of the porous material with low thermal conductivity, coat a layer of 0.5mm thick silicone rubber adhesive, after room temperature vulcanization, lay 3mm on its surface with a density of 1.5g / cm 3 The micro-ablative ceramizable phenolic resin prepreg reinforced with quartz phenolic mixed fibers was sealed with a vacuum bag and cured at 160°C for 4 hours to form a multi-level density gradient thermal protection material.

Embodiment 2

[0066] The reinforcement of the low-density heat insulation layer adopts a density of 0.12g / cm 3 Quartz fiber mat with a size of 300×300×20mm; the resin matrix is made of modified methoxysilane resin with a viscosity of 30cP and a gel time of 100°C / 4h. It is molded and cured by RTM molding process, and the resin curing temperature is 120°C , The curing time is 12 hours, and a low-density heat insulation layer is formed after curing. On the surface of the porous material, a layer of 1.5mm thick methyl phenyl vinyl silicone rubber is coated, and after room temperature vulcanization, it is wound on its surface for 10mm with a density of 1.2g / cm 3 The high-silicone phenolic mixed fiber-reinforced phenolic resin prepreg is sealed with a vacuum bag and cured at 160°C for 4 hours to form a multi-level density gradient thermal protection material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com