Borosilicate glass medicinal tube and production method thereof

A technology of borosilicate glass and production method, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of uneven chemical composition, peeling off, etc., and achieve the effect of avoiding glass debris and better performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

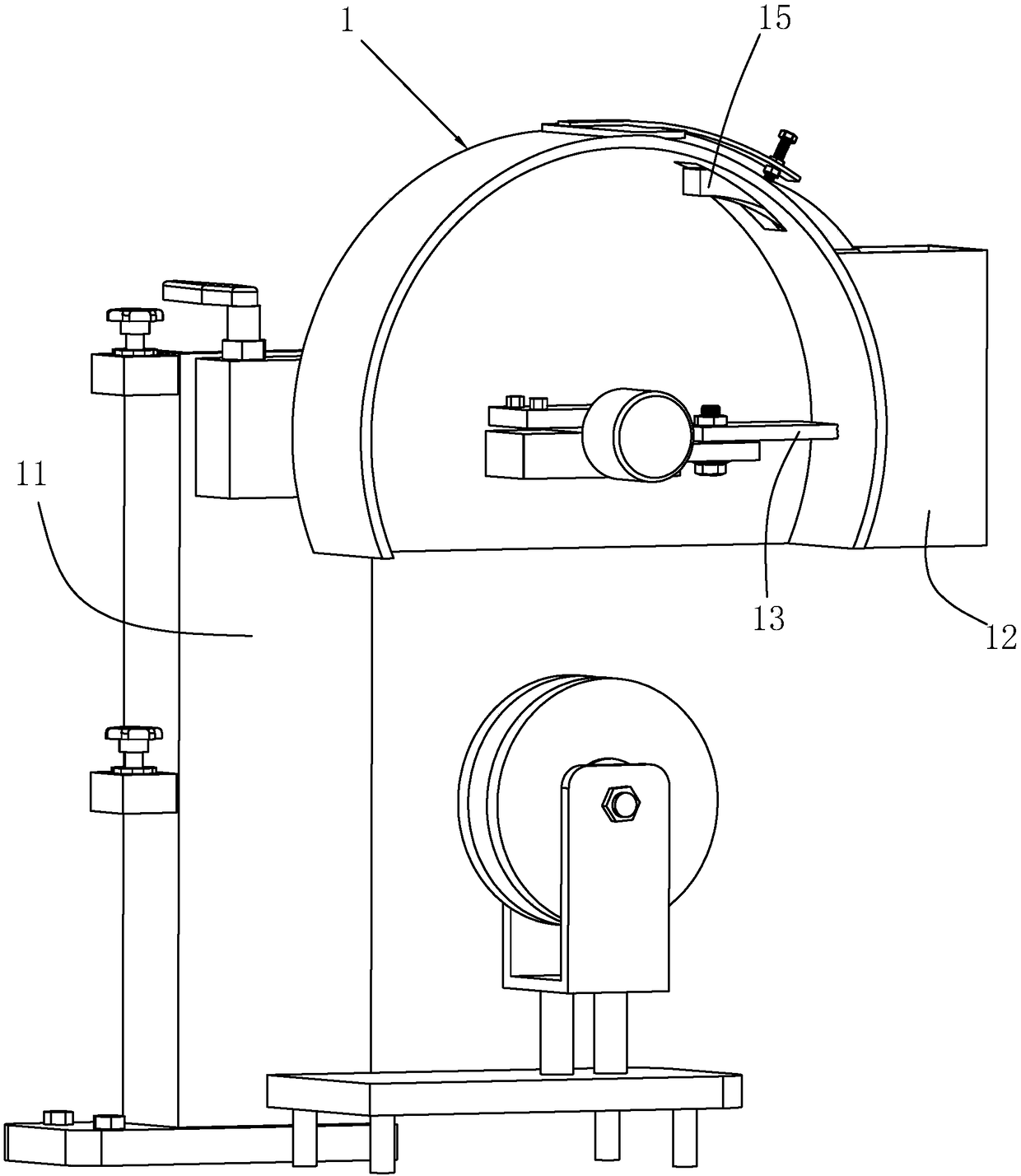

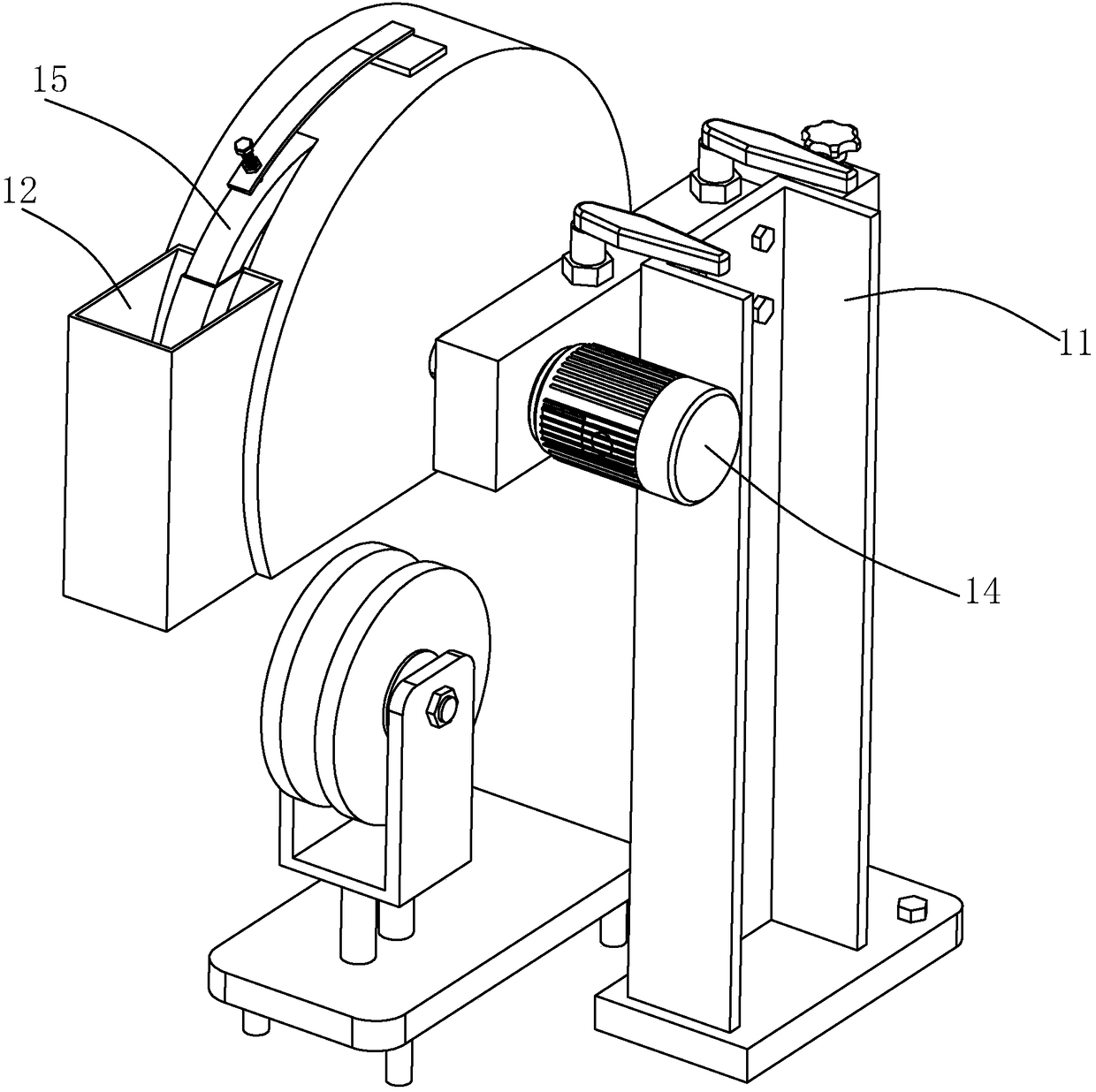

Image

Examples

Embodiment 1

[0046] A borosilicate glass medical tube, comprising 140kg of borax, 400kg of quartz sand, 24kg of spodumene, 24kg of lepidolite, 252kg of cullet, 3kg of vanadium oxide, 3kg of cerium oxide, 6kg of sodium chloride, 6kg of soda ash, Sodium sulfate 2kg.

[0047] The production method of the borosilicate glass medicinal tube comprises the following preparation steps:

[0048] Step 1: Weigh each component material of borosilicate glass medicinal tube for later use;

[0049] Step 2: adding borax, quartz sand, spodumene, and lepidolite into a blender and stirring evenly to obtain the first mixture;

[0050] Step 3: adding vanadium oxide, cerium oxide, sodium chloride, soda ash, and sodium sulfate to the first mixture and mixing evenly to obtain a second mixture;

[0051] Step 4: adding broken glass into the second mixture and stirring evenly to obtain the third mixture;

[0052] Step 5: Add the third mixed material into the kiln for melting. The melting temperature is 1500°C. The...

Embodiment 2

[0060] The difference between Example 2 and Example 1 lies in the difference in the content of glass components and the difference in process parameters during processing.

[0061] Borax 144kg, quartz sand 410kg, spodumene 28kg, lepidolite 26kg, cullet 224.8kg, vanadium oxide 3.6kg, cerium oxide 3.6kg, sodium chloride 8kg, soda ash 8kg, sodium sulfate 4kg.

[0062] The quartz sand in this embodiment is calcined by natural gas. The specific operation process is to add the quartz sand into the roasting furnace to complete the roasting process, and finally collect the calcined quartz sand for use. The temperature of roasting is best controlled at 820°C.

[0063] The production method of the borosilicate glass medicinal tube comprises the following preparation steps:

[0064] Step 1: Weigh each component material of borosilicate glass medicinal tube for later use;

[0065] Step 2: adding borax, quartz sand, spodumene, and lepidolite into a blender and stirring evenly to obtain t...

Embodiment 3

[0074] The difference between Example 3 and Example 1 lies in the difference in the content of glass components and the difference in process parameters during processing.

[0075] Borax 150kg, quartz sand 420kg, spodumene 32kg, lepidolite 28kg, broken glass 204kg, vanadium oxide 4kg, cerium oxide 4kg, sodium chloride 6kg, soda ash 6kg, sodium sulfate 2kg.

[0076] The quartz sand in this embodiment is selected from the quartz sand roasted by thermal plasma. The specific equipment used is a plasma generator, and nitrogen is used as the discharge gas. The gas enters the plasma generator after the flow is controlled by the rotameter. , the gas is ionized in the plasma generator to generate a high temperature plasma jet. The temperature at the jet outlet is 3500°C, and the quartz sand enters the plasma jet outlet from the feeding outlet through the valve control, and is rapidly heated to above 1600°C by the plasma jet in the reactor section. The treated quartz sand enters the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com