Fibre cement plate with high doping quantity of fly ash

A technology of fiber cement board and fly ash, which is applied in the field of building materials, can solve the problems of shrinkage value reduction, board flexural strength reduction, board bulk density reduction, etc., and achieve the effects of optimizing performance, increasing consumption, and good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

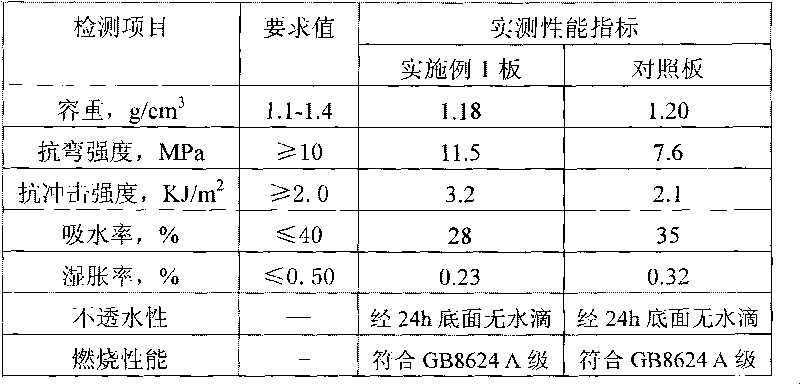

Embodiment 1

[0026] The following method is used to prepare an economical lightweight decorative board with high fly ash content, and the specific method includes the following steps:

[0027] (1) Weigh 9kg of vinylon fiber, 3kg of pulp, and 13.5kg of fibrous sepiolite, pour it into a debonder for 10 minutes, put it into a beater, and then add 2.4kg of aluminum hydroxide, 10mm chopped glass 3kg of fiber, 15kg of silica fume, 9kg of mica, 111kg of fly ash, 9kg of residual ash from a biological power plant, 9kg of anhydrite, 116.1kg of 42.5# ordinary Portland cement and water, stirred for 15 minutes to form a slurry, and the concentration of the slurry was controlled at 10~22% (percentage of dry material / (dry material + water)).

[0028] (2) The slurry is drawn into a slab by a forming machine, and the linear pressure of the forming cylinder is controlled at 0.5-0.6 MPa.

[0029] (3) The slab is subjected to steam curing, the initial temperature entering the curing kiln is not higher than 4...

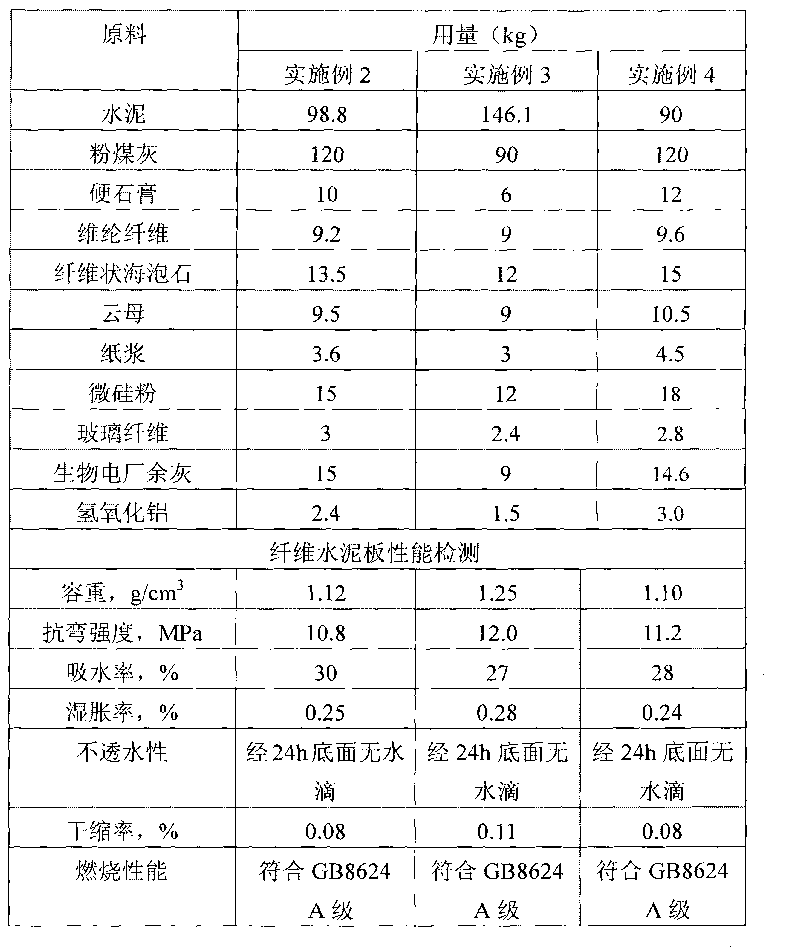

Embodiment 2~4

[0037] According to the method of Example 1, the fiber cement board was prepared with the raw materials listed in Table 2. The test results of the plates are also listed in Table 2.

[0038] Table 2 Combination of raw materials and physical and mechanical properties of fiber cement boards with different fly ash content

[0039]

[0040] The test results show that all the fiber cement boards prepared by the present invention meet the standard of medium density boards, and the strength reaches the index of Class III non-asbestos boards.

[0041]On the other hand, under the premise of meeting the standard, the amount of fly ash in the raw material of the board can be up to 40%, which can maximize the utilization of industrial waste fly ash; also, the amount of cement in the raw material of the present invention is reduced to below 50% According to a comprehensive estimate, the production cost of the present invention can be reduced by about 15% compared with similar fiber cem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com