Refrigerant distributor for heat exchanger and heat exchanger

一种制冷剂分配器、热交换器的技术,应用在热交换设备、制冷和液化、蒸发器/冷凝器等方向,能够解决分层现象,由于重力作用,液态制冷剂在下方,气态制冷剂在上方等问题,达到减轻分层现象、混合均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

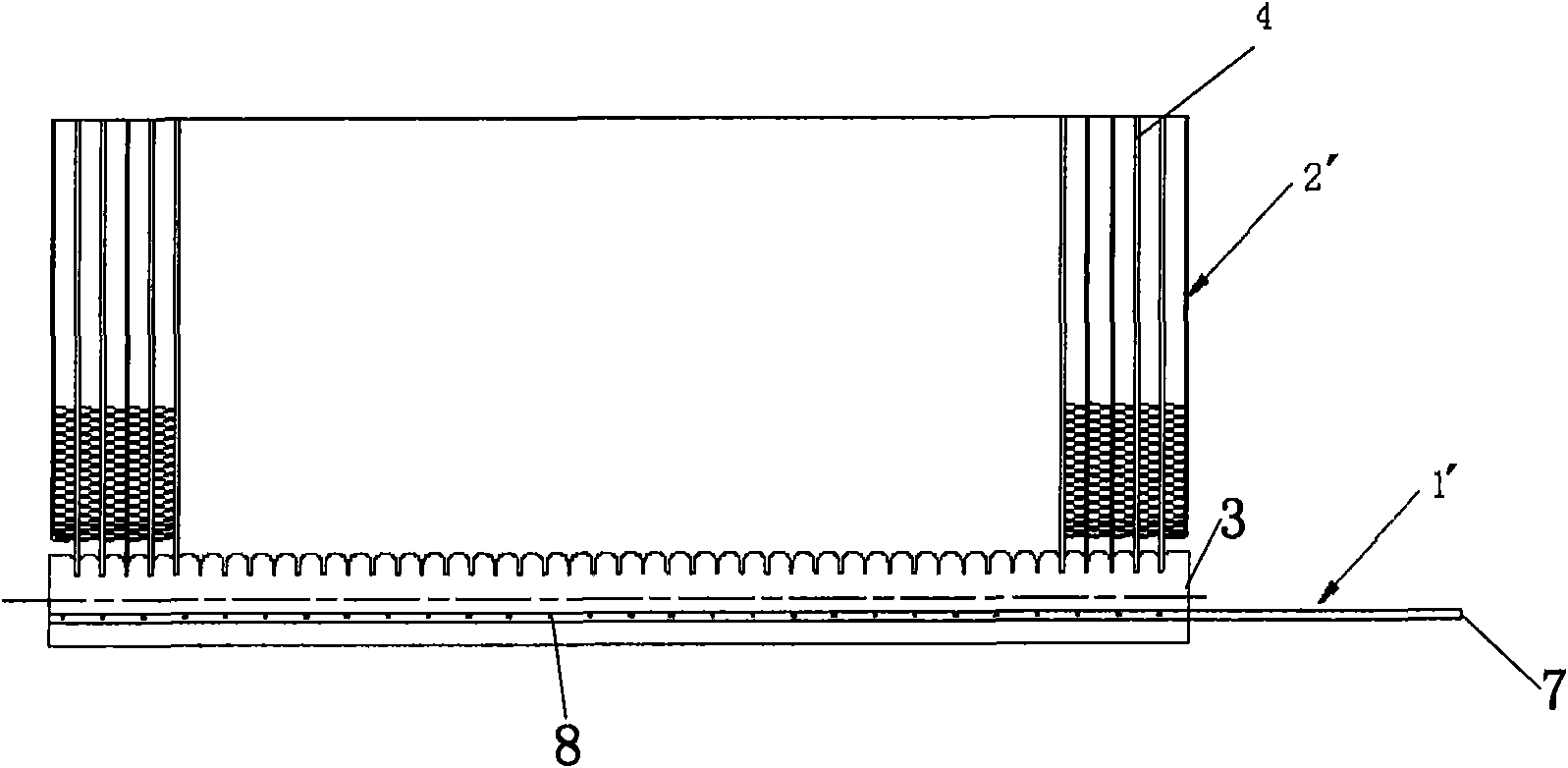

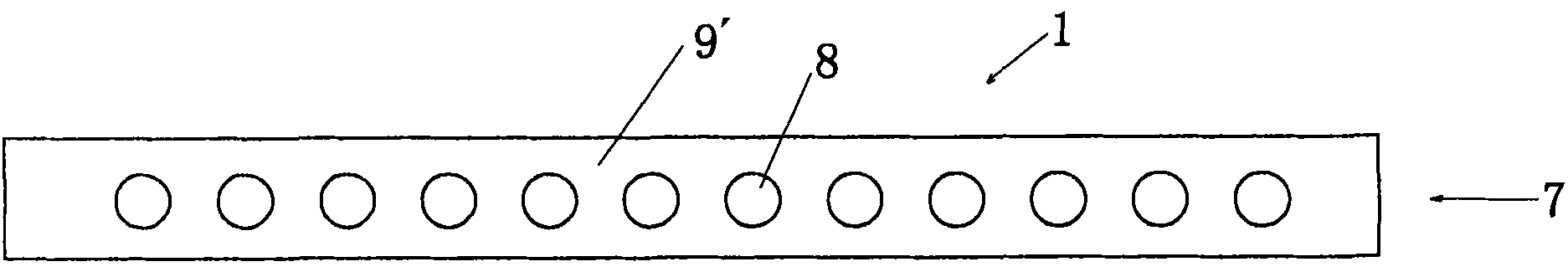

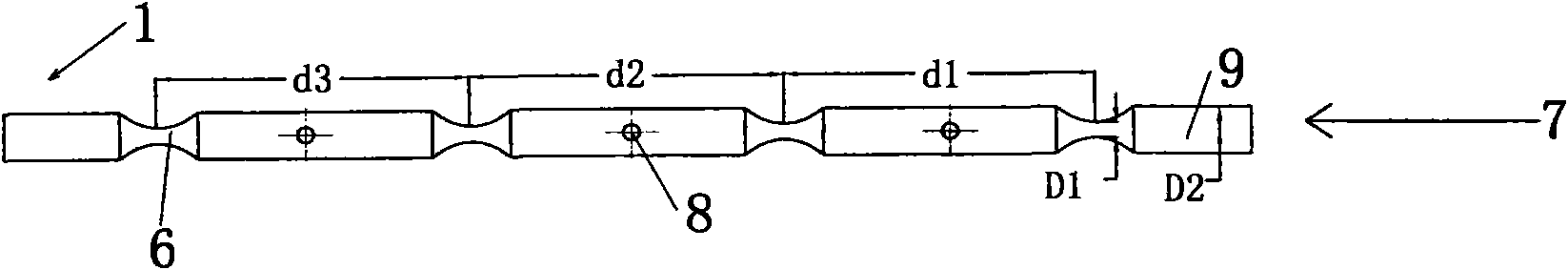

[0029] image 3 is a schematic front view of the refrigerant distributor according to the first embodiment of the present invention. Figure 4 yes image 3 A schematic top view of the refrigerant distributor shown. Figure 5 yes image 3 A perspective view of the refrigerant distributor shown. Such as Figure 3-5 As shown in , the distributor 1 comprises a round tube 9 . The circular tube 9 includes a plurality of outlets 8 for refrigerant outflow and inlets 7 for refrigerant inflow.

[0030] The diameter of the circular tube 9 shrinks to a predetermined diameter at regular intervals in the length direction of the circular tube 9 to form a necking section 6 as an example of a part with a reduced cross-sectional area, that is, D2 Figure 3-4 The right side of the middle enters the distributor 1, and every time it passes through a necking section 6, the refrigerant is sprayed once, so that the two-phase refrigerant is mixed evenly, a part of the refrigerant is sprayed out th...

Embodiment 2

[0037] A refrigerant distributor according to a second embodiment of the present invention will be described below. Image 6 is a schematic perspective view of a refrigerant distributor according to a second embodiment of the present invention. Figure 7 yes Image 6 Schematic front view of the refrigerant distributor shown. Figure 8 yes Image 6 A schematic top view of the refrigerant distributor shown. Such as Figure 6-8 As shown in , the distributor 1 comprises a round tube 9 . The circular tube 9 comprises a plurality of outlets 8 for the outflow of refrigerant. The difference from the first embodiment is that the flattened section 6', which is an example of a part with a reduced cross-sectional area, is different from the necked section 6 in the above-mentioned first embodiment. This flattened section 6' is convenient to process, and can be made In the shape of a flattened duckbill, such as Figure 6-8 shown in .

[0038] The distributor of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com