Silicon dioxide colloid pole plate and preparation method and application thereof

A silica and colloid technology, applied in battery electrodes, lead-acid battery electrodes, electrical components, etc., to reduce water loss, reduce resistance, and reduce usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

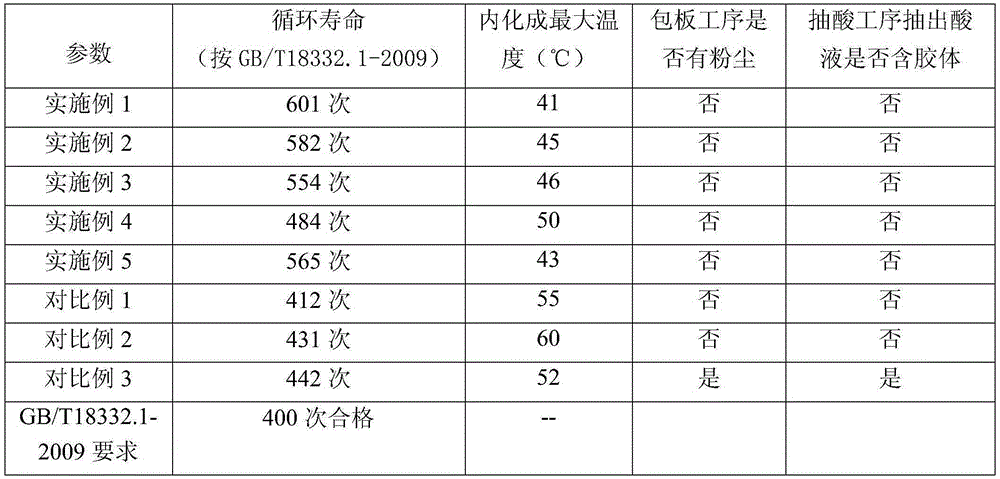

Examples

Embodiment 1

[0030] (1) Coating: Place the raw plate on the gluing machine, the plate relies on the vacuum suction cup to absorb the plate lug, close the vacuum suction cup, the plate falls on the chain, the chain hook drives the plate, and the mass fraction is 0.2wt % silica colloidal aqueous solution was spray-coated on the upper and lower sides of the raw electrode plate, and then stood still for 0.5h to obtain a wet electrode plate.

[0031] (3) Drying: The wet plate is transported to the surface drying kiln by a chain hook, and it is dried by three stages of temperature control. h; the second stage is at 200°C, and the drying time of the second stage is 0.5h; the third stage is at 160°C, and the drying time of the third stage is 1h; a silica colloidal plate is obtained. After measurement, the moisture content of the prepared silica colloidal plate was 0.3%.

Embodiment 2

[0033] (1) Pretreatment: completely immerse the raw plate in dilute sulfuric acid aqueous solution with a density of 1.06g / mL, soak the positive plate for 40 minutes, and soak the negative plate for 20 minutes, then dry it at 30-60°C for 1- 2h, get the acid-leached plate;

[0034] (2) Coating: Place the acid leached plate on the gluing machine, the plate relies on the vacuum suction cup to absorb the plate lug, close the vacuum suction cup, the plate falls on the chain, the chain hook drives the plate, and the mass fraction is 0.3 The wt% silica colloidal aqueous solution was spray-coated on the upper and lower sides of the raw electrode plate, and then left to stand for 0.5h to obtain a wet electrode plate.

[0035] (3) Drying: The wet plate is transported to the surface drying kiln by a chain hook, and is dried by three stages of temperature control. h; the second stage is 210°C, and the drying time of the second stage is 0.7h; the third stage is 160°C, and the drying time ...

Embodiment 3

[0037] (1) Pretreatment: Immerse the raw plate completely in dilute sulfuric acid aqueous solution with a density of 1.09g / mL, soak the positive plate for 50 minutes, and soak the negative plate for 25 minutes, then dry it at 30-60°C for 1- 2h, get the acid-leached plate;

[0038] (2) Coating: Place the acid leached plate on the gluing machine, the plate relies on the vacuum suction cup to absorb the plate lug, close the vacuum suction cup, the plate falls on the chain, the chain hook drives the plate, and the mass fraction is 0.3 The wt% silica colloidal aqueous solution was spray-coated on the upper and lower sides of the raw electrode plate, and then left to stand for 0.5h to obtain a wet electrode plate.

[0039] (3) Drying: The wet plate is transported to the surface drying kiln by a chain hook, and it is dried by three stages of temperature control. h; the second stage is 210°C, and the drying time of the second stage is 0.6h; the third stage is 180°C, and the drying ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com