Improvement method of sandy clay loam saline-alkaline soil

A saline-alkali soil and soil technology is applied in the improvement field of sandy clay loam saline-alkali soil, and achieves the effects of hindering the rise of capillary water, low production cost and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take soil samples from the plow layer (0-20cm) in the sandy clay loamy saline-alkali soil area to be improved, and analyze the mechanical composition after air drying (see Table 1). The soil bulk density is 1.32g / cm 3 . Take iron tailing sand samples and analyze the mechanical composition (see Table 2).

[0038] Table 1. Mechanical composition of sandy clay loamy saline-alkali soil

[0039] Particle size classification

<0.002mm

0.002≤~<0.05mm

0.05≤~<2mm

content(%)

21.1

26.6

52.3

[0040] Table 2. Mechanical composition of iron tailings

[0041] Particle size classification

<0.002mm

0.002≤~<0.05mm

0.05≤~<2mm

content(%)

8.4

68.2

23.4

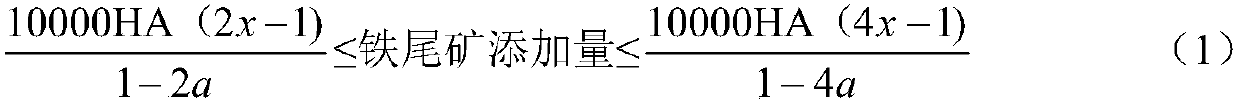

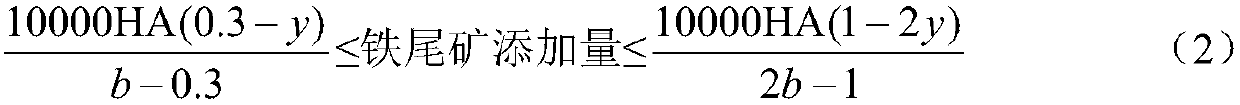

[0042] Select 30m in the area to be improved 2 After the plot is leveled, add 850kg of iron tailings sand to the soil according to the formula (1) and (2), and mix it evenly with the plow layer soil (depth 20cm), and set the control plot 1 (30m 2 , with...

Embodiment 2

[0050] The mechanical composition of the plow layer soil in the sandy clay loamy saline-alkali soil area to be improved is the same as Table 1, and the soil bulk density is 1.32g / cm 3 . The mechanical composition of iron tailings is the same as Table 2.

[0051] Mix iron tailings with hydrolyzed polymaleic anhydride with a molecular weight of 400-800, a solid content of 48-50%, and a 1% aqueous solution with a pH of 2-3, stir evenly, adjust the pH of the iron tailings to 6.0, and obtain modified iron tailings sand.

[0052] Select 30m in the area to be improved 2 After the plot is leveled, add 850kg of modified iron tailings sand to the soil according to the formula (1) and (2), and then mix it evenly with the plow layer soil (20cm depth), and set the control plot 1 (30m 2 , undisturbed soil), control plot 2 (30m 2 , adding iron tailings without adding organic acid) for farming, the planting crop is corn, and other planting operations and management are the same as those i...

Embodiment 3

[0060] Take the dewatered sludge with a water content of 80%±5 and a pH of 8.5±0.5 from a domestic sewage treatment plant and mix it evenly with corn straw powder to control the C / N ratio of 25 to 35:1. After composting, the sludge with a water content of 25.7% and a pH of 8.3 is obtained Decomposed sludge.

[0061] The mechanical composition of the plow layer soil in the sandy clay loamy saline-alkali soil area to be improved is the same as Table 1, and the soil bulk density is 1.32g / cm 3 . The mechanical composition of iron tailings is the same as Table 2. Select 30m in the area to be improved 2 After leveling the plot, add 850kg of iron tailings to the soil according to formula (1) and (2), mix evenly with the plow layer soil, then add 60kg of decomposed sludge, mix evenly with the mixed soil, and let it stand for a month , set control plot 1 (30m 2 , undisturbed soil), according to plot 2 (30m 2 , adding decomposed sludge but no iron tailings sand), control plot 3 (30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com