Blocky carpet and preparation method thereof

A carpet and block technology, which is applied in the direction of carpets, chemical instruments and methods, and synthetic resin layered products, can solve the problems of easy delamination of carpets, difficulty in bonding, and large differences in asphalt performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

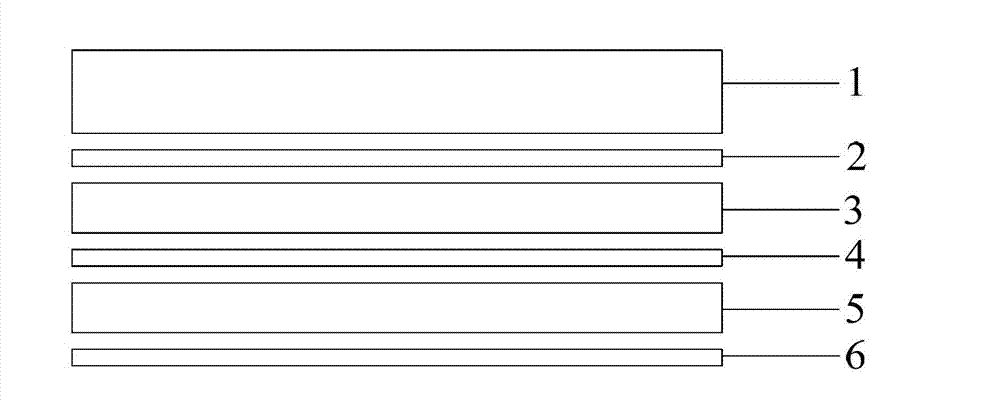

[0024] The invention provides a method for preparing a block carpet, which comprises the following steps: A) EVA glue is coated on the back of the blank carpet, and after heating and reacting, a blank carpet with a waterproof layer is obtained, and the EVA glue contains 30 to 50 wt. The ethylene-vinyl acetate copolymer of 10~50 parts by weight, the calcium carbonate of 10~50 parts by weight, the auxiliary material of 1~2 parts by weight, the insoluble silicate material of 8~40 parts by weight, the water of 10~20 parts by weight; B ) Coat the second PU adhesive layer on the non-woven protective layer, then press the second PU adhesive layer with the glass cloth, after the first heating and curing reaction, then coat the first PU adhesive layer, and then combine with the The blank carpet containing the waterproof layer is rolled and subjected to a second heating and curing reaction to obtain a block carpet.

[0025] The source of the gray carpet described in this aspect is not p...

Embodiment 1

[0042] 1.1 the ethylene-vinyl acetate copolymer of 42 parts by weight, the calcium carbonate of 25 parts by weight, the auxiliary material of 2 parts by weight, the portland cement of 17 parts by weight are mixed with the water of 14 parts by weight, obtain EVA glue, described auxiliary material For penetrating agent, dispersant and foaming agent.

[0043] 1.2 After foaming the EVA glue obtained in 1.1, coat it on the back of the green carpet, scrape it flat with a scraper, put it in an oven at 125°C for curing reaction and dry it to obtain a green carpet with a waterproof layer.

[0044] 1.3 Coat the PU adhesive on the smoke gray non-woven fabric, then press the PU adhesive with the glass cloth, heat curing reaction at 130°C for 5 minutes, then coat another layer of PU adhesive on the glass cloth, and mix with the obtained in 1.2 The green carpet containing the waterproof layer is pressed together, rolled with a composite roller and an extrusion roller, and heat-cured at 150°...

Embodiment 2

[0049] 2.1 the ethylene-vinyl acetate copolymer of 40 parts by weight, the calcium carbonate of 12 parts by weight, the auxiliary material of 2 parts by weight, the Portland cement of 30 parts by weight are mixed with the water of 16 parts by weight, obtain EVA glue, described auxiliary material For penetrating agent, dispersant and foaming agent.

[0050] 2.2 After foaming the EVA glue obtained in 2.1, coat it on the back of the green carpet, scrape it flat with a scraper, put it in an oven at 125°C for curing reaction and dry it to obtain a green carpet with a waterproof layer.

[0051] 2.3 Coat the PU adhesive on the smoke gray non-woven fabric, then press the PU adhesive with the glass cloth, heat curing reaction at 130°C for 5 minutes, then coat another layer of PU adhesive on the glass cloth, and mix with the obtained in 2.2 The green carpet containing the waterproof layer is pressed together, rolled with a composite roller and an extrusion roller, and subjected to a hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com