Novel lead-free environment-friendly high-strength wear-resistant copper-base alloy bar and preparation method thereof

An alloy rod and high-strength technology is applied in the field of preparation of lead-free, environmentally friendly, high-strength, wear-resistant copper-based new alloy rods and alloy rods. It can solve the problems of poor machinability, hot embrittlement, and lead environmental hazards, and achieve machinability Excellent, avoiding environmental pollution, and beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

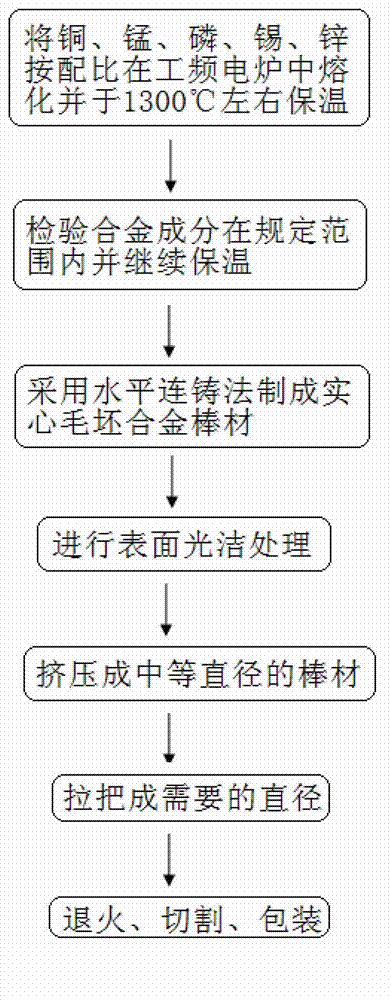

[0028] A new lead-free, environmentally friendly, high-strength, wear-resistant copper-based alloy rod, which is composed of the following components in weight percentage: manganese 1%-3%, tin 2%-4%, phosphorus 0.01%-0.5%, zinc 1.5%-4.5% %, the balance is copper. Its preparation method is as figure 1 As shown, specifically:

[0029] Step 1: Place electrolytic copper, manganese, phosphorus, tin, and zinc in a power frequency electric furnace according to the proportion, heat to 1230°C-1350°C to completely melt, and cool down to 1300°C.

[0030] Step 2 After fully stirring the completely melted alloy liquid with a special graphite tool, cover it with high-purity scaly graphite powder to prevent its oxidation, with a thickness of about 15-20 cm.

[0031] Step 3 After the holding time of 50 to 60 minutes, the composition of the sample taken out of the furnace is inspected three times with a direct-reading spectrometer imported from Germany to confirm that the alloy composition i...

Embodiment 2

[0037] A lead-free, environmentally friendly, high-strength, wear-resistant copper-based new alloy rod is composed of the following components in weight percentages: 1% manganese, 2% tin, 0.01% phosphorus, 1.5% zinc, and the balance is copper. Its preparation method is as figure 1 As shown, specifically:

[0038] Weigh each component according to the formula, put it in a power frequency electric furnace and melt it, (stir evenly with a special graphite rod) cover it with 15cm of high-purity scaly graphite powder to prevent oxidation, and keep it warm for about 50 minutes. Check whether the alloy composition is within the specified range. After the test is completed and qualified, continue to keep warm for about 30 minutes, then raise the temperature to 1350°C, turn on the vibration device, and cast a solid blank alloy bar by horizontal continuous casting method. The surface is processed to make the surface smooth, and then extruded by an extruder (the extrusion temperature is...

Embodiment 3

[0040] A lead-free, environmentally friendly, high-strength, wear-resistant copper-based new alloy rod is composed of the following components in weight percentage: 3% manganese, 4% tin, 0.5% phosphorus, 4.5% zinc, and the balance is copper. Its preparation method is as figure 1 As shown, specifically:

[0041] Weigh each component according to the formula, put it in a power frequency electric furnace and melt it, (stir evenly with a special graphite rod) cover it with 20cm of high-purity scaly graphite powder to prevent oxidation, and keep it warm for about 60 minutes. Check whether the alloy composition is within the specified range. After the test is completed and qualified, continue to keep warm for about 35 minutes, then raise the temperature to 1350°C, turn on the vibration device, and use the horizontal continuous casting method to cast a solid rough alloy bar. The surface is processed to make the surface smooth, and then extruded by an extruder (the extrusion temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com