A kind of glass transparent thermal insulation coating and preparation method thereof

A heat-insulating coating, transparent technology, applied in coatings and other directions, can solve problems such as poor thermal insulation performance, and achieve the effect of simple coating components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a novel transparent heat-insulating coating for glass surfaces and a preparation method thereof. The coating contains a general formula of Cs 0.1-3.5 WO 3 Cesium tungsten bronze powder, the crystal phase composition of the powder is Cs 0.2 WO 3 or Cs 0.32 WO 3 , the powder particle size is 100~1300nm, the specific surface area is 7~50m 2 / g. The preparation method of the coating includes the step of mixing the above-mentioned cesium tungsten bronze powder with a film-forming agent, polyvinyl butyral (PVB), polyvinyl alcohol (PVA) or collodion. The cesium tungsten bronze powder described in the present invention is prepared by the following method:

[0025] ① Prepare a precursor solution containing tungstic acid, cesium carbonate and reducing substances according to the Cs / W molar ratio of 0.01 to 0.35:1, and the solvent is water or a mixture of ethanol and water in a volume ratio of 1:4 to 4:1;

[0026] ②The precursor solution is placed in...

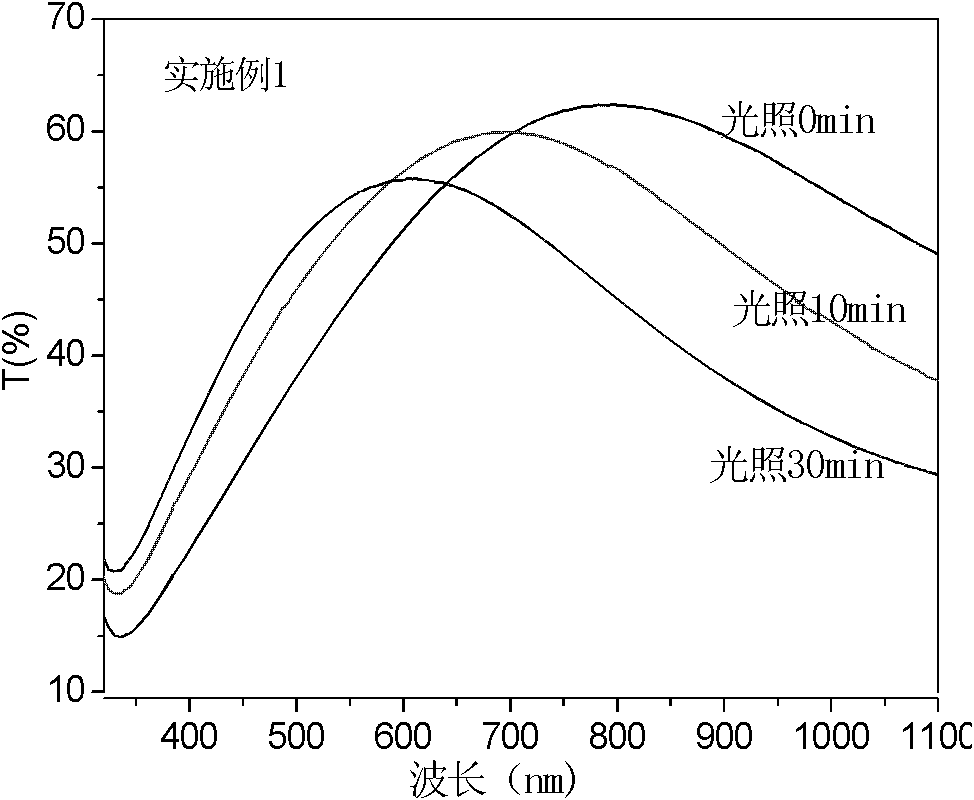

Embodiment 1

[0054] ① Preparation of Cs with Cs / W (molar ratio) = 0.3:1 0.3 WO 3 Powder.

[0055] Weigh a certain amount of sodium tungstate, dissolve it in deionized water, and prepare a 0.5mol / L sodium tungstate solution, and use styrene cation exchange resin to ion-exchange the sodium tungstate solution to obtain 0.5mol / L tungstic acid solution; measure 20ml of 0.5mol / L tungstic acid solution, put it into a beaker, add 30ml of 2mol / L citric acid solution once during stirring, slowly add 5ml of 0.3mol / L cesium carbonate solution dropwise, and continue stirring for 1h. Get prepared Cs 0.3 WO 3 Powder reaction precursor solution; transfer the reaction precursor solution prepared above into an autoclave, and conduct a continuous hydrothermal reaction at 200°C for 3 days; wash the reacted precipitate with water and alcohol three times in sequence, and after centrifugation , dried at 50°C for 10 h in a sub-vacuum to obtain blue Cs 0.3 WO 3 Powder.

[0056] ②Preparation of polyvinyl alc...

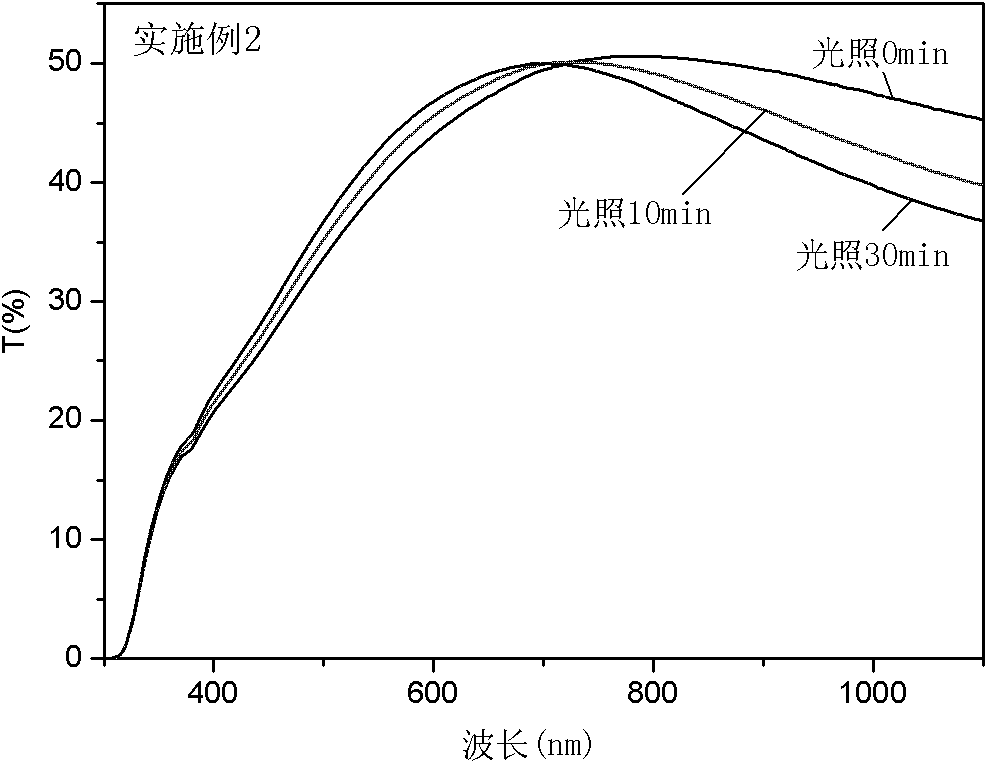

Embodiment 2

[0062] ① Preparation of Cs with Cs / W (molar ratio) = 0.3:1 0.3 WO 3 Powder.

[0063] Weigh a certain amount of sodium tungstate, dissolve it in deionized water, and prepare a 0.5mol / L sodium tungstate solution, and use styrene cation exchange resin to ion-exchange the sodium tungstate solution to obtain 0.5mol / L tungstic acid solution; measure 20ml of 0.5mol / L tungstic acid solution, put it into a beaker, add 12.6g of citric acid once during stirring, after stirring evenly, slowly add 5ml of 0.3mol / L cesium carbonate solution dropwise, and then add 10ml Absolute ethanol and 20ml deionized water, continue to stir for 1h, obtain preparation Cs 0.3 WO 3 Powder reaction precursor solution; transfer the reaction precursor solution prepared above into an autoclave, and conduct a continuous hydrothermal reaction at 190°C for 3 days; wash the reacted precipitate with water and alcohol three times in sequence, and after centrifugation , dried at 50°C for 10 h in a sub-vacuum to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com