Elastic brass alloy and preparation method thereof

A brass alloy and elasticity technology, applied in the field of elastic brass alloy and its preparation, can solve the problem of not developing a preparation process, and achieve the effect of improving strength and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

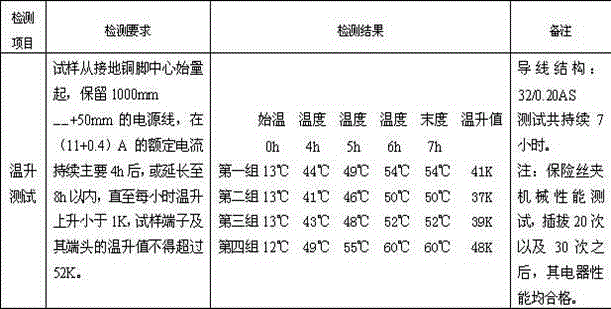

Image

Examples

Embodiment 1

[0021] Use a 50Kg intermediate frequency induction furnace for melting, first add Cu-Ni master alloy and electrolytic copper, the melting temperature is 1100-1150°C, after melting, add zinc ingots, Al wire, and finally add Cu-Cr master alloy, then pour, the temperature is 1080 ~1130°C. Iron mold casting is used, the size of the ingot is 60mm×120mm×450mm, and the size after milling is 48mm×120mm×450mm. The alloy composition is as follows:

[0022] Copper is 70% by weight, zinc is 24% by weight, aluminum is 3% by weight, nickel is 2.5% by weight, and chromium is 0.5% by weight, wherein the impurities in copper and zinc are each less than 0.1% by weight.

[0023] Elastic brass alloy according to hot rolling - solution treatment - pickling - rough rolling - annealing - pickling - middle rolling - annealing - pickling - pre-finishing - annealing - pickling - finishing rolling - aging treatment - pickling - classification Bar-pack process preparation. The elastic brass alloy fini...

Embodiment 2

[0036] The composition of the alloy is: 71% by weight of copper, 25% by weight of zinc, 2% by weight of aluminum, 1% by weight of nickel, and 1% by weight of chromium, wherein the impurities in copper and zinc are each less than 0.1% by weight.

[0037] Preparation method is basically the same as Example 1, the difference is:

[0038] Solution treatment, heat in a box-type annealing furnace at 800°C for 90 minutes, then raise the temperature to 910°C for 1-3 minutes, then quickly put the sample into a water pool for quenching until the sample is cooled below 50°C, and remove the sample from Remove from the pool.

[0039] For aging treatment, heat in a box-type annealing furnace at a temperature of 200-300°C and a holding time of 1.5-2 hours.

[0040] Alloy strength and elasticity are shown in Table 3

[0041] Table 3 Alloy properties

[0042] Sample category Tensile strength (Mpa) Elongation (%) Elastic modulus (Gpa) Conductivity (%IACS) Hardness (HV) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com