Integrated forming manufacturing method of I-shaped beam made from composite material

A composite material, integral molding technology, applied in the field of composite materials, can solve the problems of low connection strength, reinforced composite material I-beam, material damage, etc., and achieve the effect of improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0022] The present invention comprises the following steps:

[0023] Step 1, the preparation of mold

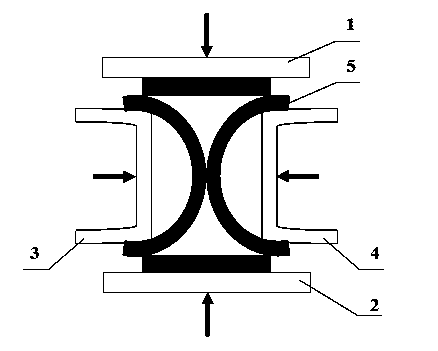

[0024] Such as figure 1 As shown, the mold is composed of 4 mold plates, which are upper mold plate 1, lower mold plate 2, left mold plate 3 and right mold plate 4;

[0025] Step 2. Fiber cloth cutting, dipping and lamination

[0026] Composite material fiber cloth is cut in two sizes, one size specification is the fiber cloth of the wing plate, and the other size specification is the fiber cloth of the web plate; after the cut fiber cloth is fully dipped in resin, according to the composite material I In the beam loading direction, the fiber cloth is laminated to obtain 4 fiber cloth laminates dipped in resin and in a wet state;

[0027] Step 3, the fiber cloth stack is placed in the mold

[0028] Such as figure 1 As shown, after applying the release ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com