Process method for replacing trunnion of ladle

A process method and trunnion technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of insignificant heating effect of the package body, freezing trunnions, inadvisability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

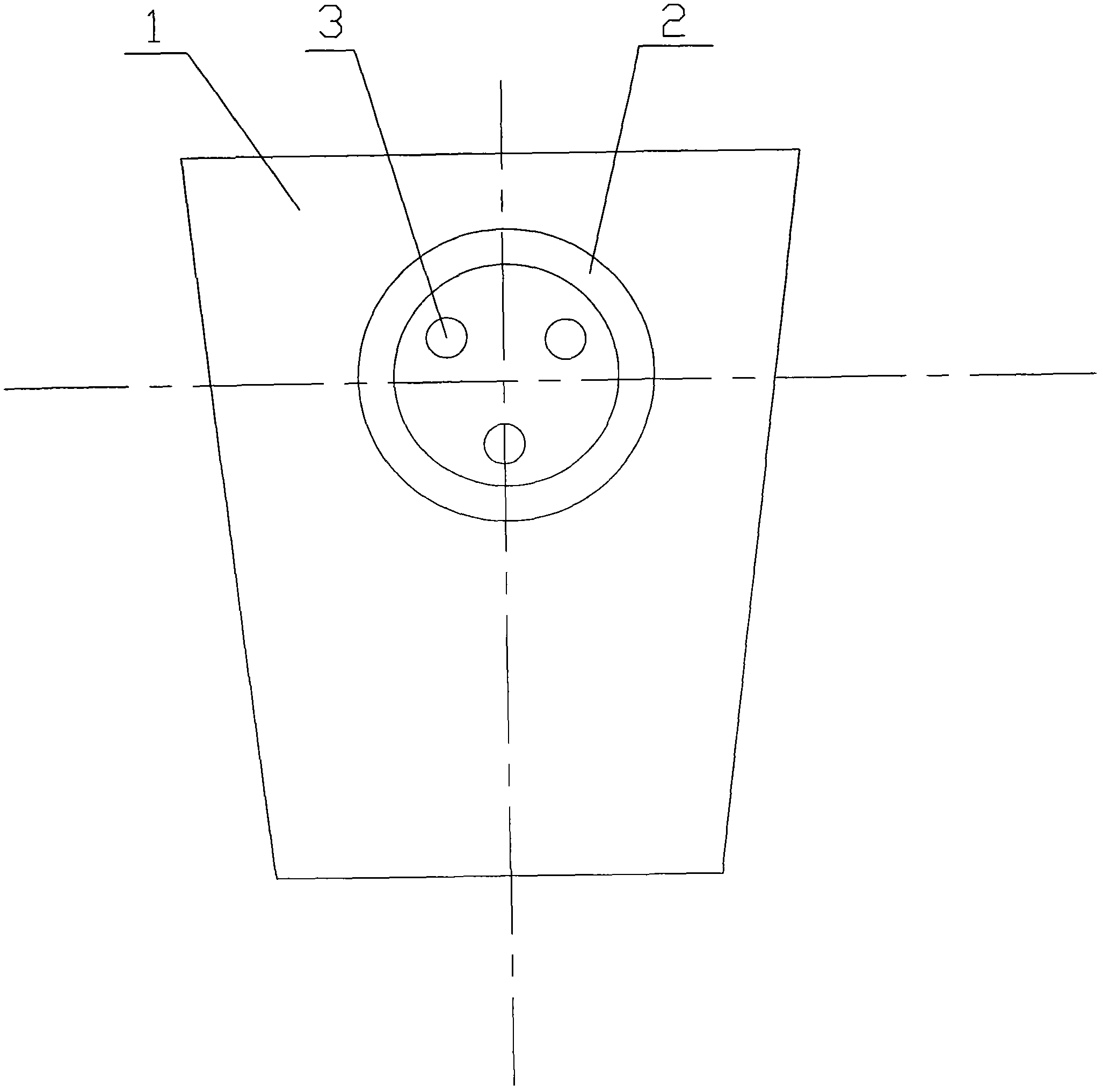

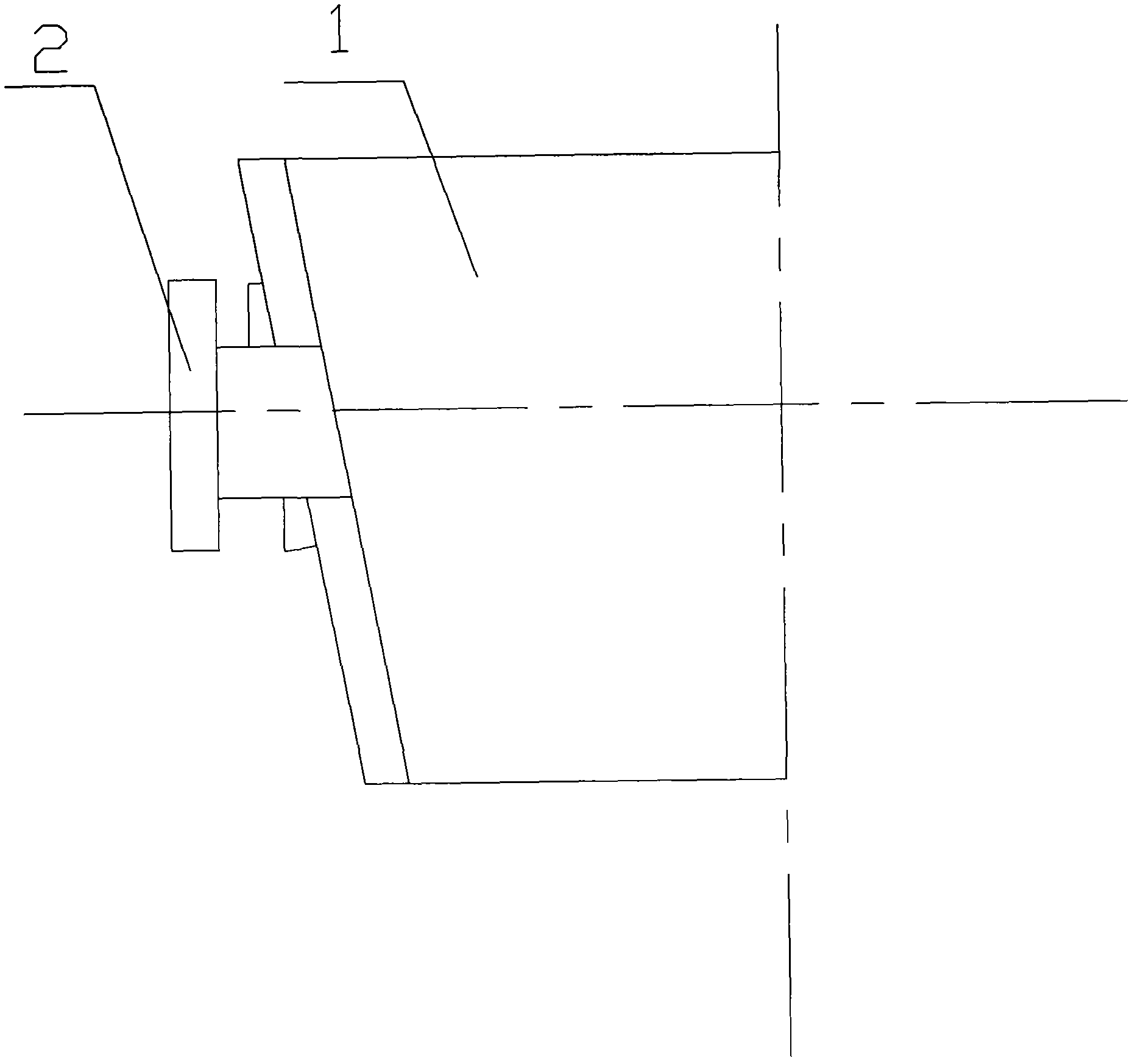

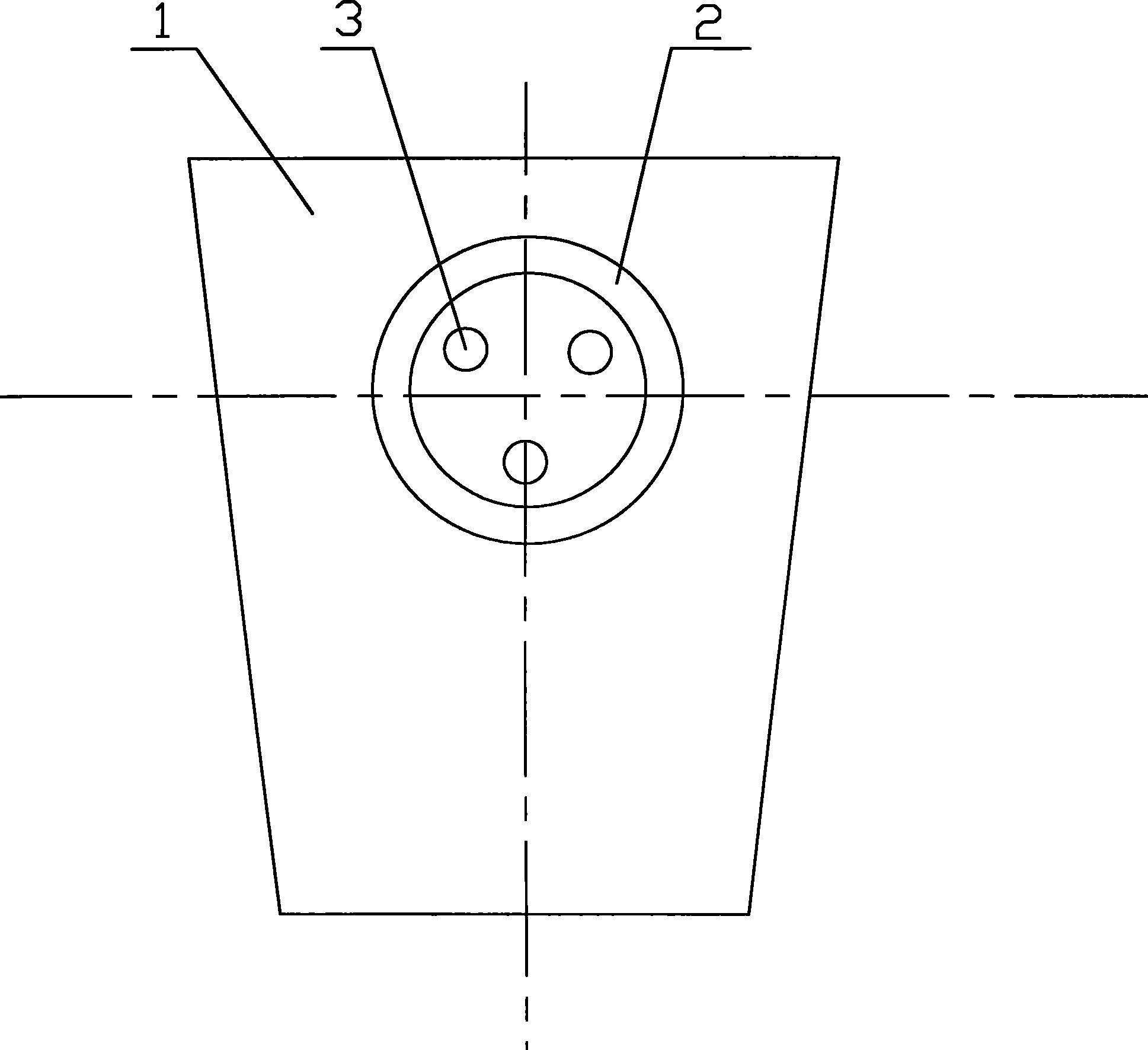

[0025] A process for replacing the ladle trunnion, the structure diagram of the ladle is as follows figure 2 shown.

[0026] First, the trunnion 2 extends out of the steel ladle 1 for cutting off, and planes off the welding seam at the joint between the trunnion 2 and the steel ladle 1;

[0027] Then, the end face of the trunnion 2 is spaced at a certain distance to form a triangular shape and heated with an oxy-acetylene flame cutting torch to liquefy the metal at these three parts;

[0028] After the metal in the heated part is liquefied, use a high-pressure oxygen blowing pipe to blow oxygen at these three parts, and use the chemical reaction between iron and oxygen to blow out three holes 3 in these parts, such as figure 1 As shown, in this process, due to the rapid heating of the trunnion 2, the trunnion 2 expands rapidly, and the connecting hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com