Manufacturing process for circuit board with long and short gold fingers

A circuit board manufacturing and gold finger technology, which is applied in the directions of printed circuit components, electrical connection printed components, and printed component electrical connection formation, etc., can solve the problems of long production cycle, complex gold finger process, low product reliability, etc. The effect of avoiding residues, reducing the area of the physical connection structure, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

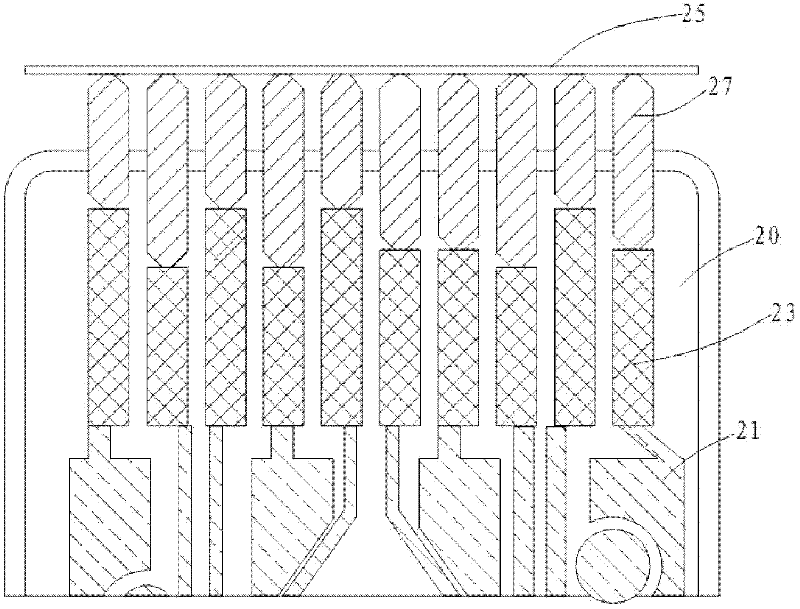

[0029] The specific implementation of the manufacturing process of the long and short gold finger circuit board of the present invention will be described in detail below with reference to the accompanying drawings.

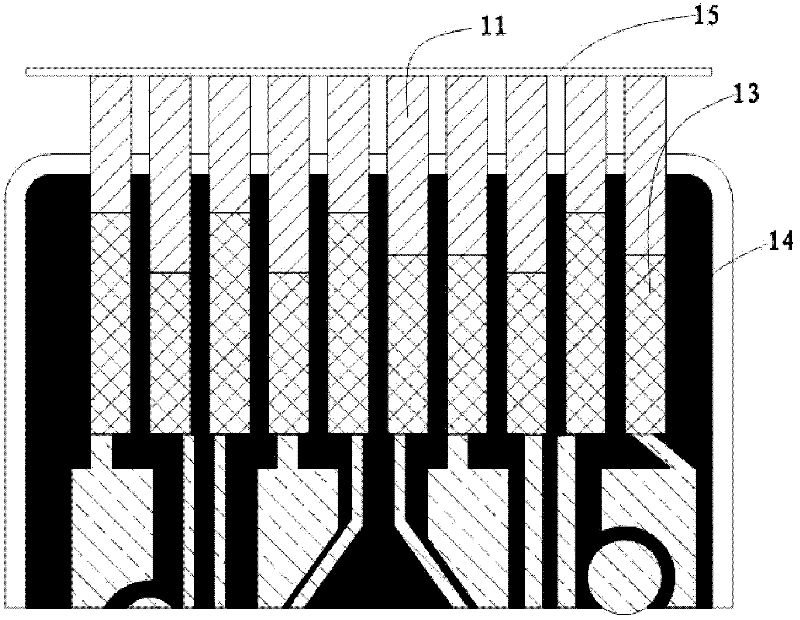

[0030] See figure 2 , Is a schematic diagram of the planar structure of a circuit board in the process of the present invention. The circuit board 2 is a rigid printed circuit board with long and short golden finger structures. The circuit board 2 includes a substrate 20, a plurality of conductive patterns 21 formed on the surface of the substrate 20, a plurality of gold fingers 23, a frame 25 and gold-plated leads 27.

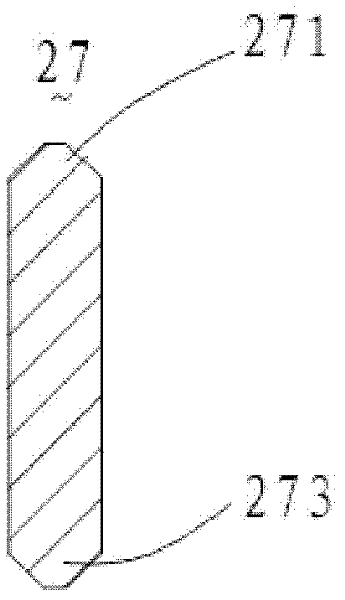

[0031] The substrate 20 is a carrier substrate processed from an insulating resin material for carrying the conductive pattern 21, a plurality of gold fingers 23, a frame 25, and a gold-plated lead 27 on its surface. The gold-plated lead 27 is electrically connected to the plurality of gold fingers 23 correspondingly. At the same time, the gold-pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com