Socket pipe piece of heat melted connection

A socket-insertion and hot-melt technology, which is applied in the direction of pipes/pipe joints/pipes, pipeline connection arrangement, mechanical equipment, etc. The effect of avoiding false melting or false welding, improving connection strength and improving work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

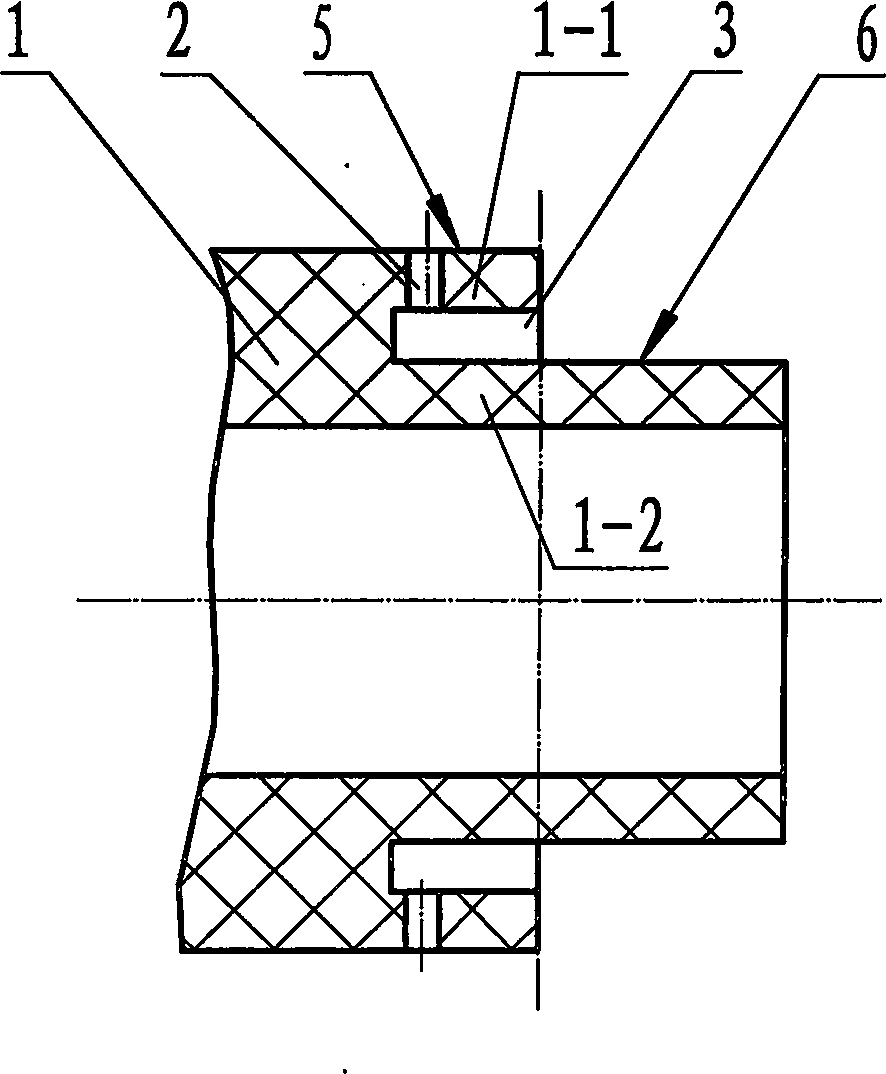

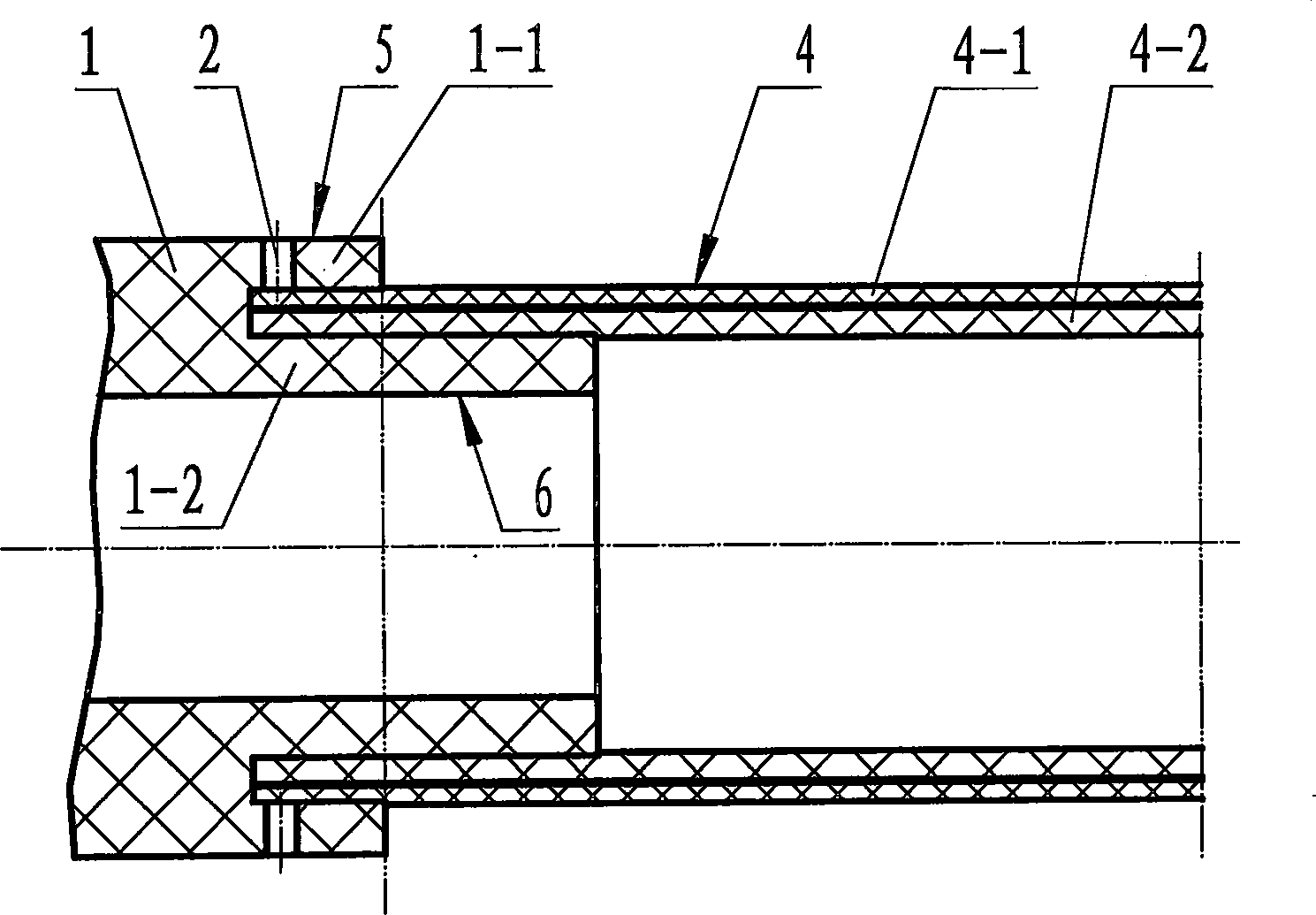

[0019] see figure 1 , figure 2 As shown, one end of a hot-melt connection socket fitting for aluminum-plastic composite pipe is a joint 1, which is composed of an inner layer connection section 6 at the front end and a socket section 5 adjacent thereto, and the inner layer connection Section 6 is equal in diameter to the inner ring 1-2 of socket section 5 and is connected as a whole. An annular socket 3 is formed between them, and four radial exhaust observation holes 2 are evenly distributed on the same circumference at the rear of the outer ring 1-1. The axial length of the inner layer connection section 6 is longer than that of the socket section 5, the inner layer connection section 6 and the outer ring surface of the inner ring 1-2 form the main connection surface of the hot-melt connection, and the inner ring surface of the outer ring 1-1 It is the sealing end surface of the aluminum-plastic composite pipe 4, which belongs to the secondary connecting surface, and the ...

Embodiment 2

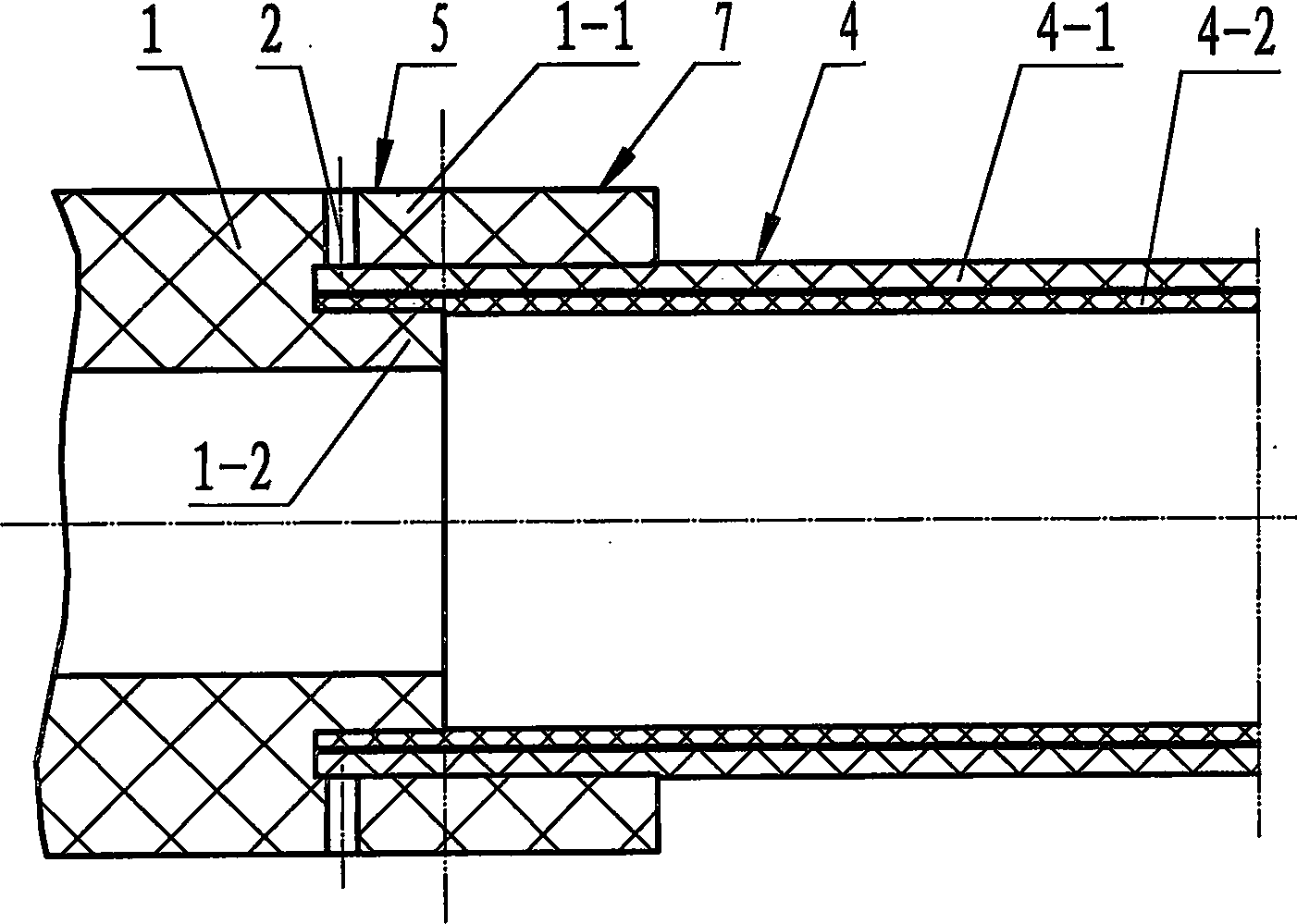

[0022] see image 3 As shown, compared with embodiment 1, the present embodiment has the following differences in the structure of joint 1:

[0023] The single-layer connection section of the joint 1 adopts the outer layer connection section 7 , which is an equal-diameter extension section of the outer ring 1 - 1 of the socket section 5 .

[0024] All the other structures are the same as in Example 1. The axial length of the outer layer connection section 7 is longer than the axial length of the socket section 5, and the outer layer connection section 7 and the inner ring surface of the outer ring 1-1 form the main connection surface of the hot-melt connection, and the inner ring 1-2 The outer ring surface of the aluminum-plastic composite pipe 4 is the sealing end surface of the aluminum-plastic composite pipe 4, which belongs to the secondary connection surface. The outer layer connecting section 7 and the pipe ring of the outer ring 1-1 are equal in diameter and wall thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com