Clay-corundum mullite composite runner brick, and production method thereof

A composite flow and mullite technology, applied in the field of refractory materials, can solve the problems that the performance cannot fully meet the needs of use, the corrosion resistance, the poor scouring ability, the high cost of the flow steel brick, etc., to achieve good rapid cooling and rapid heating performance, resistance to erosion. and erosion, good resistance to erosion and scour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

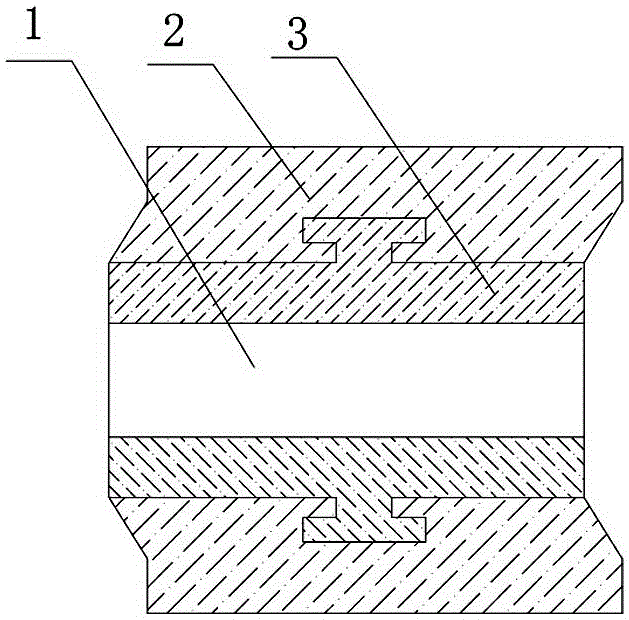

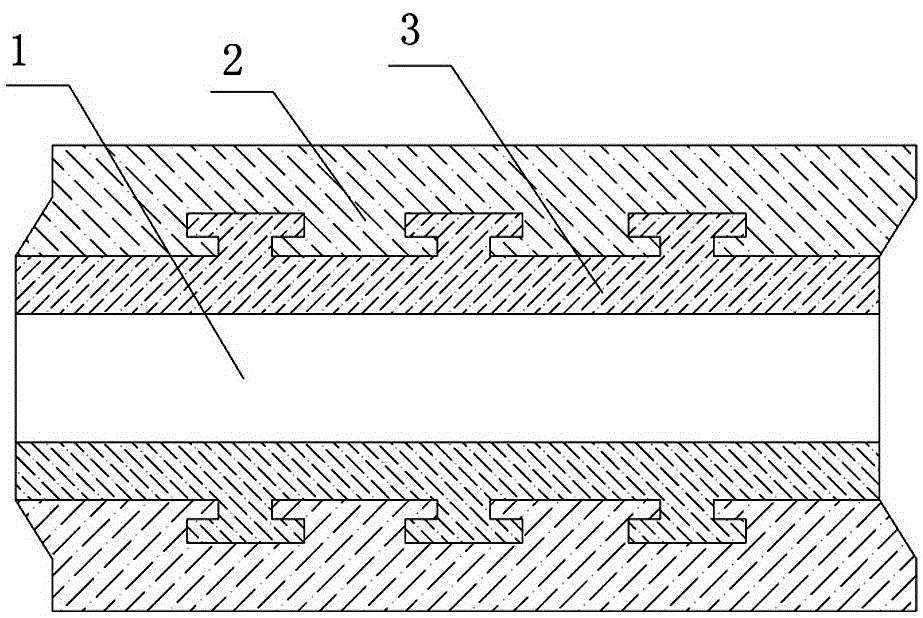

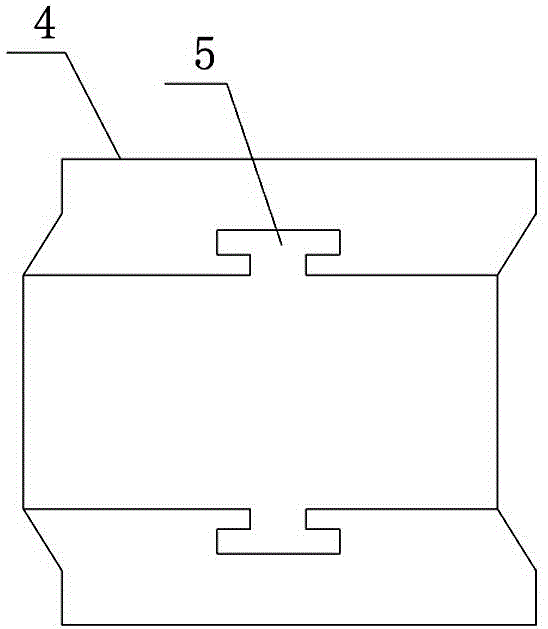

[0030] Such as figure 1 , figure 2 As shown, the clay-corundum mullite composite flow steel brick of the present invention includes a brick matrix 2 with a molten steel flow channel 1, and in order to improve its erosion resistance and corrosion resistance, a composite There is a working layer 3. In order to ensure that the working layer 3 will not be separated from the brick matrix 2 when the molten steel is poured, the joint surface of the brick matrix 2 and the working layer 3 is a cross-cut groove structure. If the length of the brick body is short, only one slot can be designed in the length direction, such as figure 1 shown; if the length of the brick body is longer, multiple slots can be designed in the length direction, such as figure 2 shown. In order to meet the requirements of smelting different special alloy steels, the thickness ratio of the brick matrix 2 and the working layer 3 can be adjusted between 60-80%: 40-20%.

[0031] Below by embodiment 1~6, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com