Treatment method for recycling waste red mud residues

A treatment method and technology for red mud, applied in chemical instruments and methods, removal and application of solid waste, etc., can solve problems such as unsuccessful development, achieve significant economic and social benefits, and the treatment method is scientific and reasonable, beneficial to The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: A treatment method for red mud waste recycling

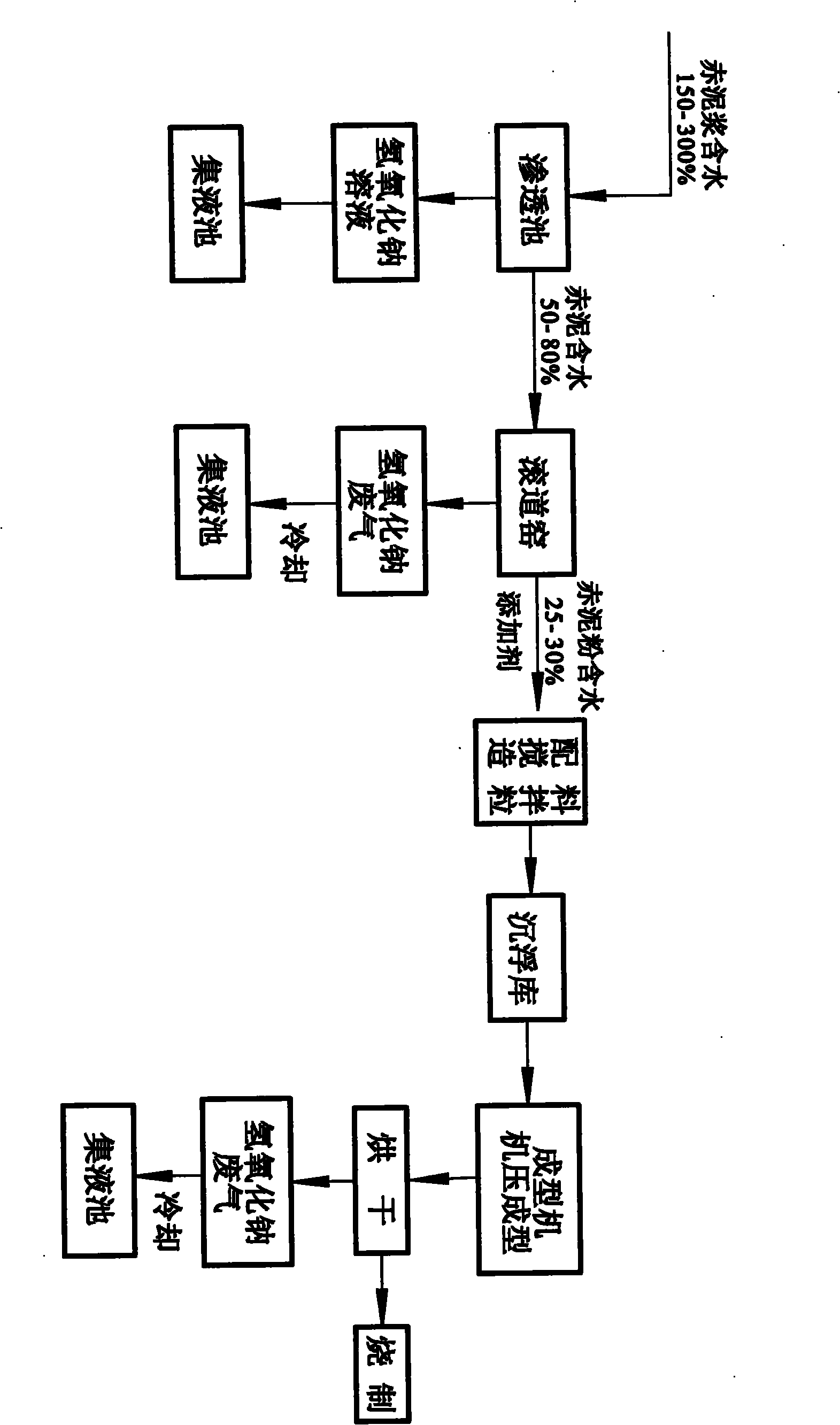

[0027] The processing method of red mud waste slag recycling of the present invention, the detailed steps of this processing method are as follows (see attached figure 1 ):

[0028] a. The red mud slurry with a moisture content of 200% transported from the alumina plant through pipeline water is injected into the osmosis tank for initial dehydration, and after dehydration, red mud with a moisture content of 60% and a sodium hydroxide solution with a pH value of 11-12 are obtained (Sodium hydroxide solution penetrates into the diversion channel from the wall and bottom of the permeation tank, and injects it into the liquid collection tank from the diversion channel), injects it into the liquid collection tank, and transports it to the alumina plant for reuse through pipelines;

[0029] b. The red mud obtained after the initial dehydration in step a is sent to the roller kiln for drying through the conveyor belt...

Embodiment 2

[0033] Embodiment two: basically the same as embodiment one, the difference is:

[0034] In step a: the water content of the red mud slurry transported from the alumina plant is 150%, and the red mud obtained after the initial dehydration in the infiltration tank has a water content of 50%;

[0035] In step c: the amount of additive added accounts for 20% of the total weight of the red mud powder, the additive is a mixture of 8% laterite and 12% fine coal powder, and the granulated mixed material sinks and floats for 6-7 hours at normal temperature in the sink-float store ;

[0036] In step d: the mixed material after sinking and floating is injected into a pressure forming machine according to a conventional method, and pressed into a brick adobe, and stacked for 1 to 3 hours;

[0037] In step e: the red mud brick adobe is dried and heated to 900±5° C. for firing.

Embodiment 3

[0038]Embodiment three: basically the same as embodiment one, the difference is:

[0039] In step a: the water content of the red mud slurry transported from the alumina plant is 300%, and the red mud obtained after the initial dehydration in the infiltration tank has a water content of 80%;

[0040] In step c: the amount of additive added accounts for 10% of the total weight of the red mud powder, the additive is a mixture of 5% laterite and 5% fine coal powder, and the granulated mixed material sinks and floats for 9 to 10 hours at normal temperature in the sinking and floating storehouse ;

[0041] In step e: after the red mud bricks are dried, the temperature is raised to 950±5° C. for firing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com