Automatic spot welding equipment

An automatic spot welding and equipment technology, applied in welding equipment, resistance welding equipment, metal processing equipment and other directions, can solve the problems of high labor intensity, difficult product welding quality, low production efficiency, etc., to improve quality and production efficiency, improve The effect of market competitiveness and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] For the convenience of those skilled in the art to understand, the following In conjunction with specific embodiment and accompanying drawing to this

[0031] Inventive structure principle is described in further detail:

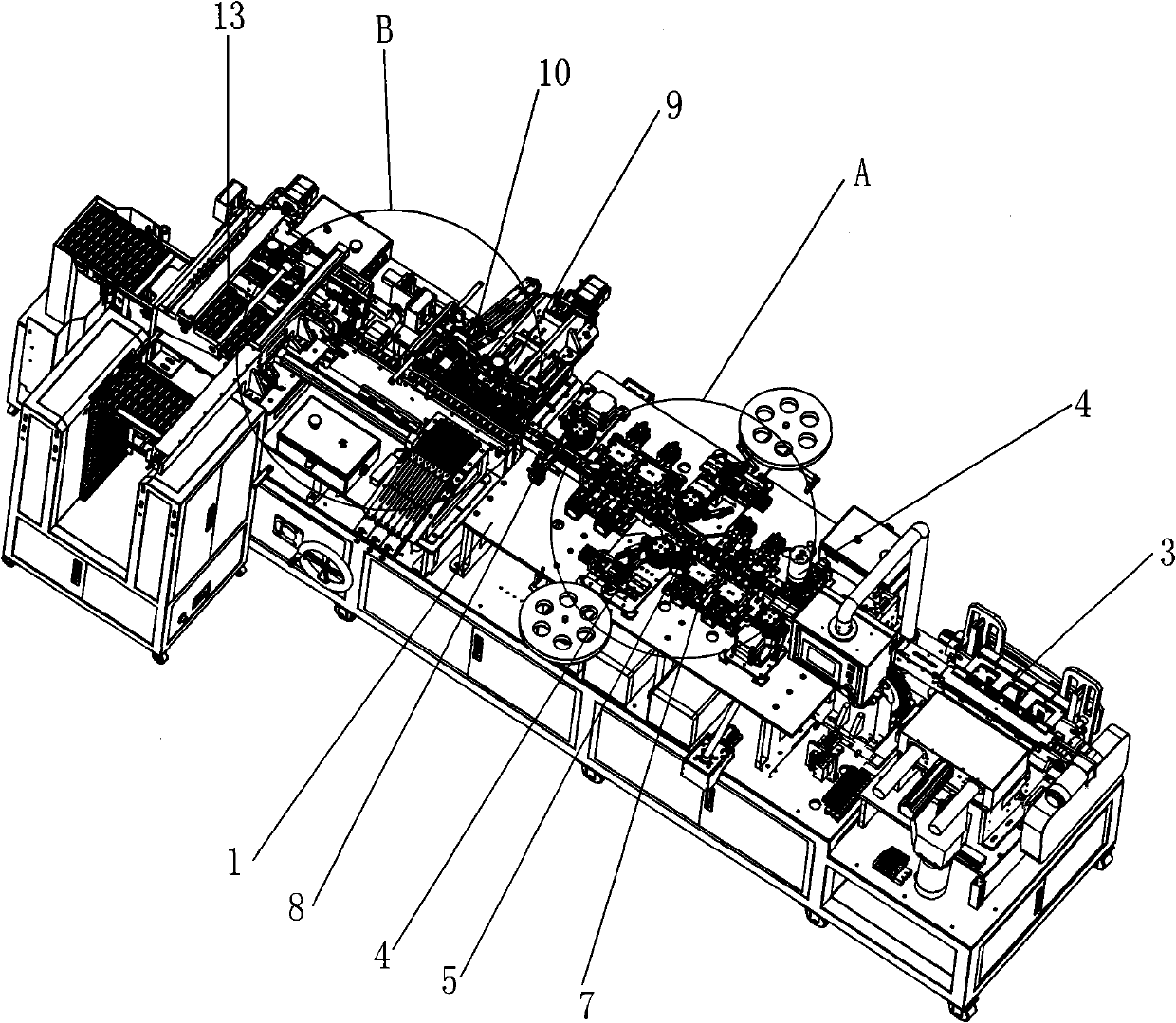

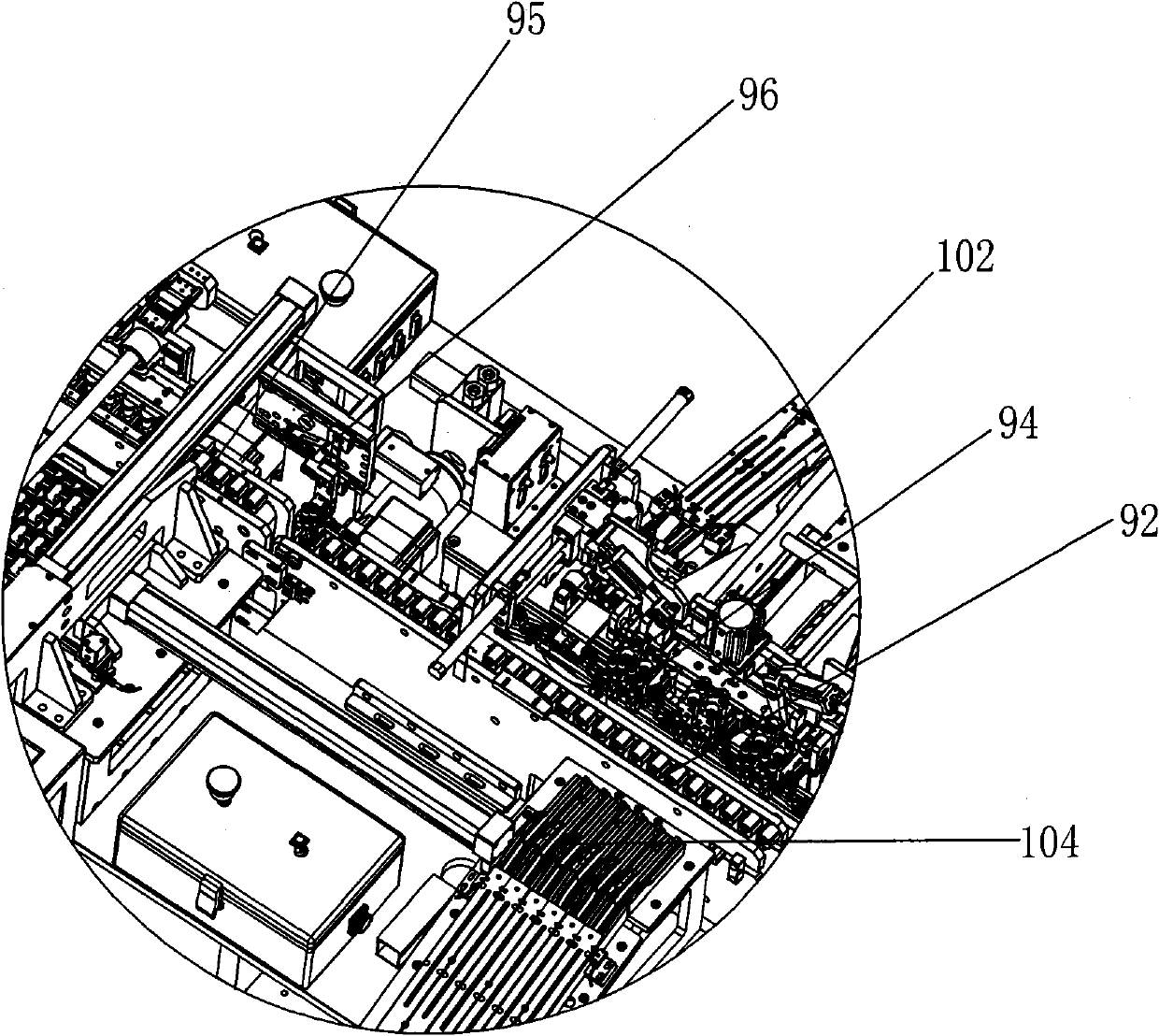

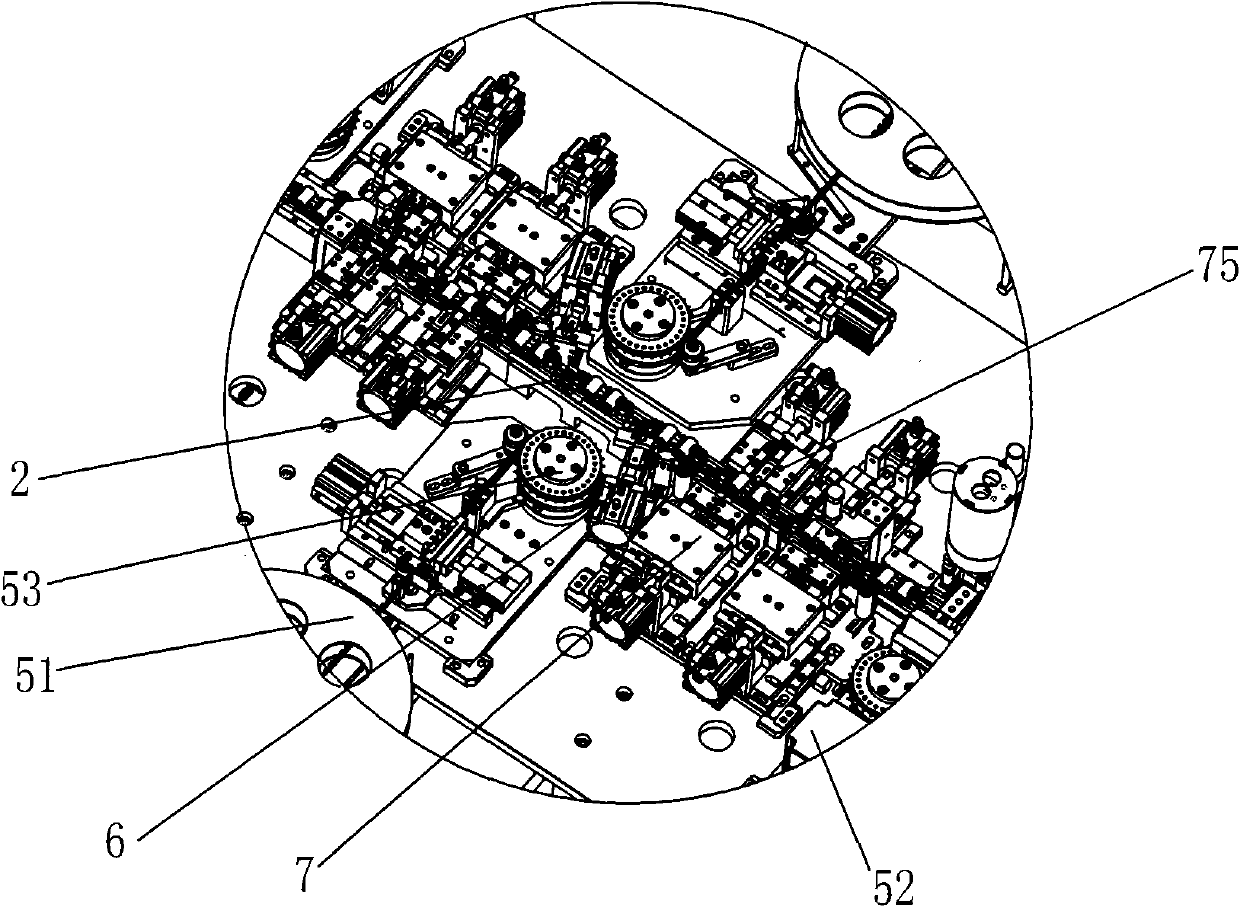

[0032] as attached Figure 1-13 , an automatic spot welding equipment, including a frame and a workbench 1 arranged on the frame, on the workbench 1, a battery feeding mechanism 3, a transfer mechanism 2, a battery label alignment mechanism 4, and a steel strip feeding mechanism are arranged in sequence 5. Solder sheet cutting mechanism 6, welding mechanism 7, reflective optical fiber detection mechanism 8, good product unloading mechanism 9, defective product recovery mechanism 10, battery feeding mechanism 3 and steel belt feeding mechanism 4 respectively The battery 11 and the steel strip 12 are sent into the welding station, the steel strip 12 is connected with a solder piece 121, the transfer mechanism 2 carries and transfers the battery 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com