Method for full-needle knitting of fully-formed sweater on double-needle-bar flat knitting machine

A bed flat knitting and full forming technology, applied in knitting, weft knitting, textile and paper making, etc., can solve the problems of loose fabric, pattern restriction, insufficient tightness, etc., and achieve the effect of tight fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

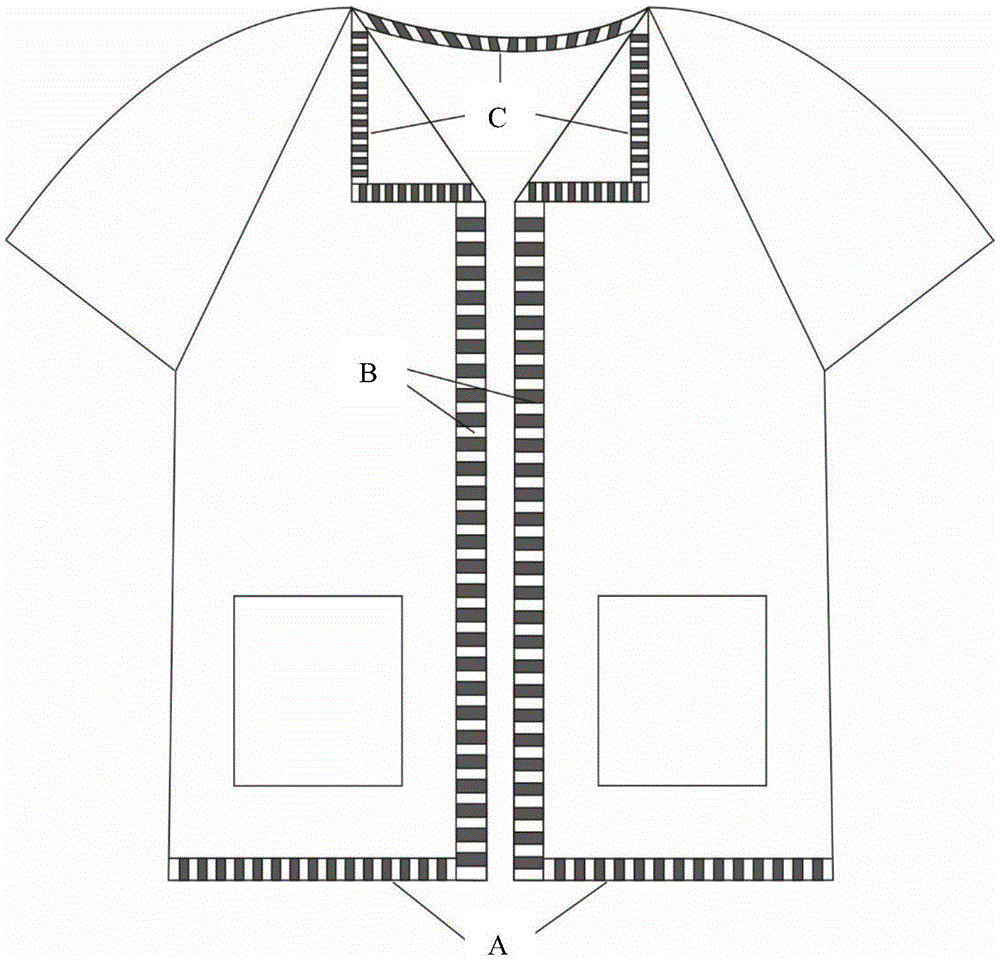

[0025] Embodiment 1, knitting a sweater cardigan with raglan sleeves, the style figure is as follows figure 1 shown.

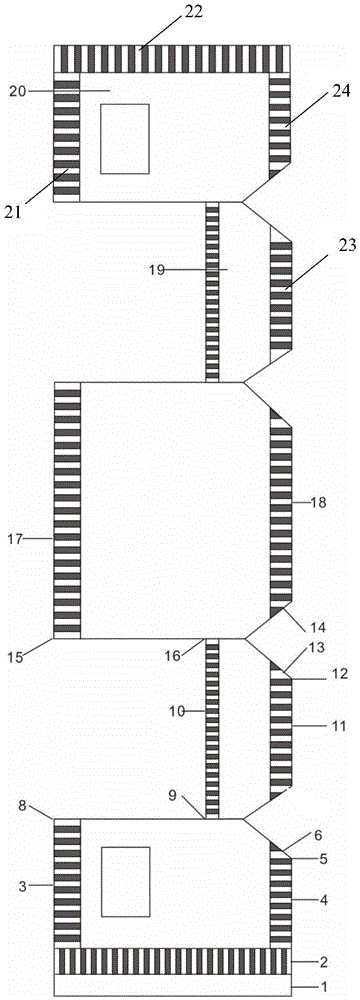

[0026] Such as figure 2 As shown, the steps are:

[0027] (1) Weaving waste yarn to start;

[0028] (2) After the waste yarn knitting is completed, weave one row alternately with one needle forward and one reverse needle, knit one row with needles on the front needle bed every other, knit one row with needles on the rear needle bed every other, and then knit one row with the front needle beds every other Knitting a row with the needle out, completing the rib opening and idling 1;

[0029] (3) After the bottoming of the waste yarn is completed, select 10 rows, and each row is formed by two needles in the front and two needles in the opposite direction to form the placket 2 of the front panel of the cardigan. The number of rows depends on the width of the design placket; select 10 wales, with two rows as a unit loop, the leftmost wale, one row is not knitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com