Independent taping embroidery device and embroidery machine comprising same

A tape embroidery and rope embroidery technology, which is applied in the field of computerized embroidery machines and embroidery machines, can solve the problems of high cost of mechanism maintenance, high requirements for gear meshing and installation, and increase the external space of the machine head, so as to improve the aesthetics and three-dimensionality The effect of sense, compact structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, where there is no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

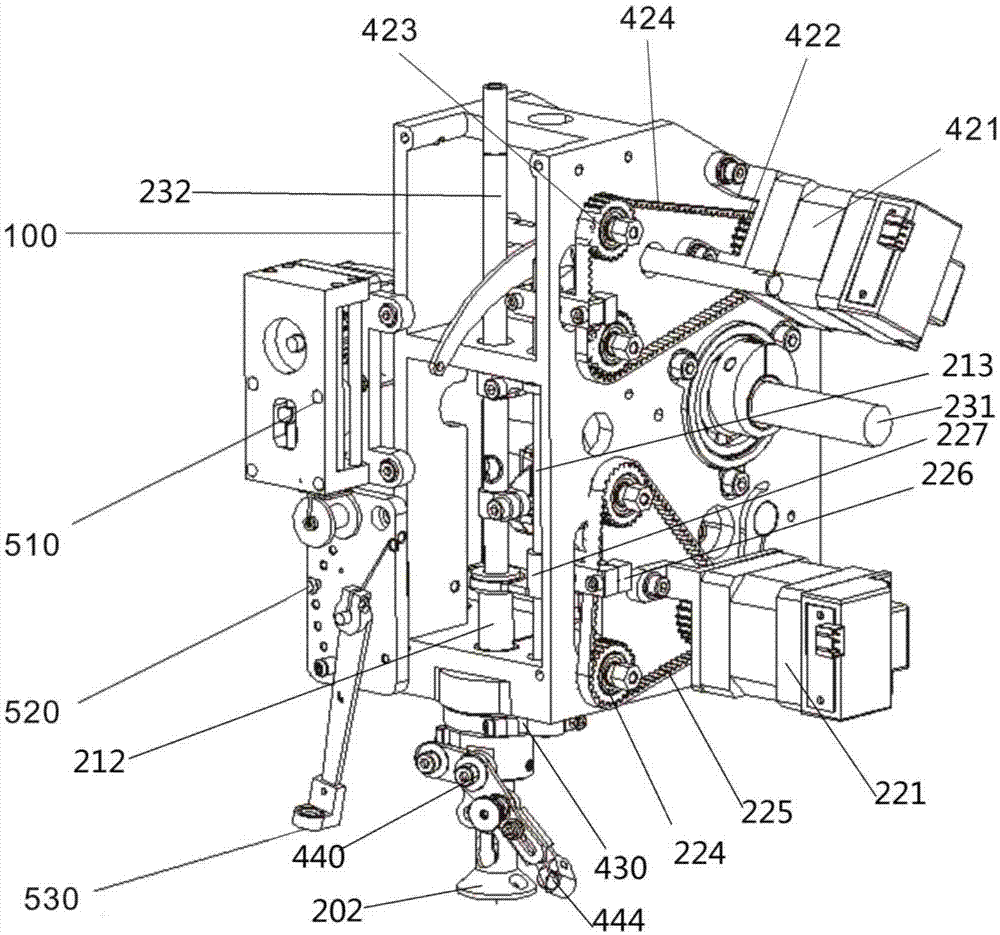

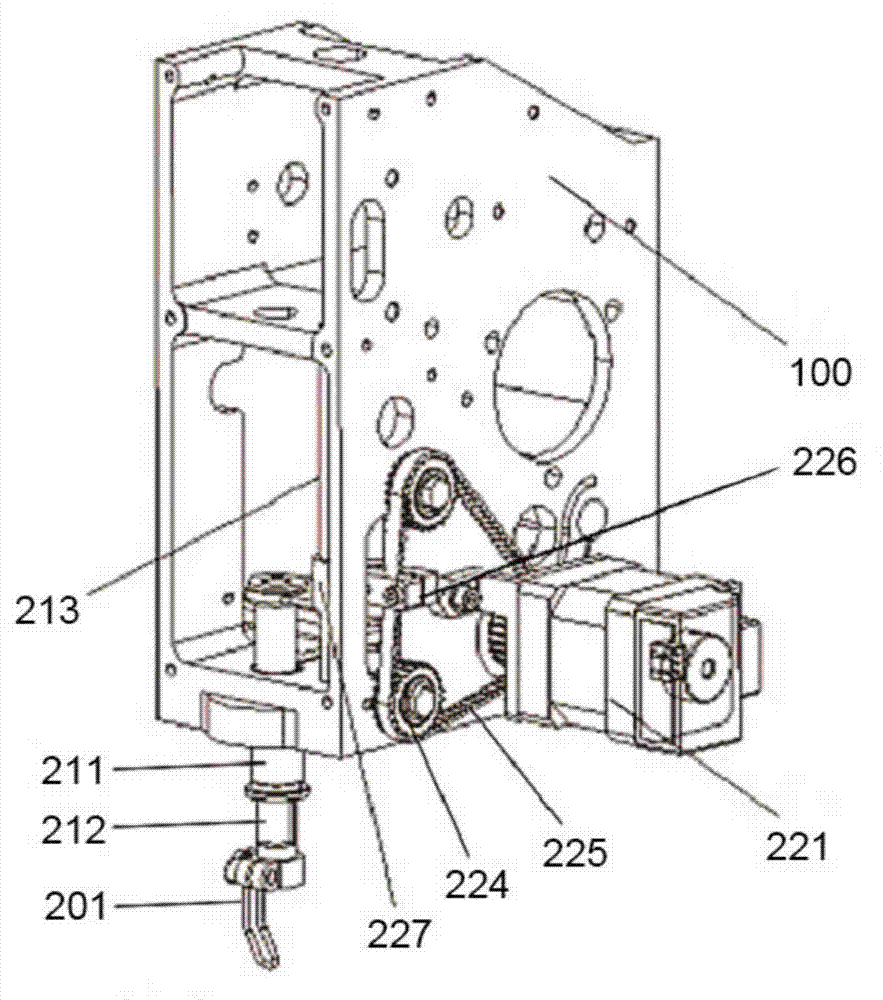

[0051] Such as figure 1 As shown, according to the embodiment of the present invention, the independent taping embroidery device includes a casing 100, a needle bar driving mechanism 230 (not shown) arranged on the casing 100, a presser foot mechanism 200, an embroidery trajectory tracking mechanism 300 and cord embroidery mechanism 400. The casing 100 provides a certain space for installing various components therein. The size of the cavity and the effective coordination of various internal components, as well as the effective work and simplicity of the structure, are the key to embodying the embroidery machine head.

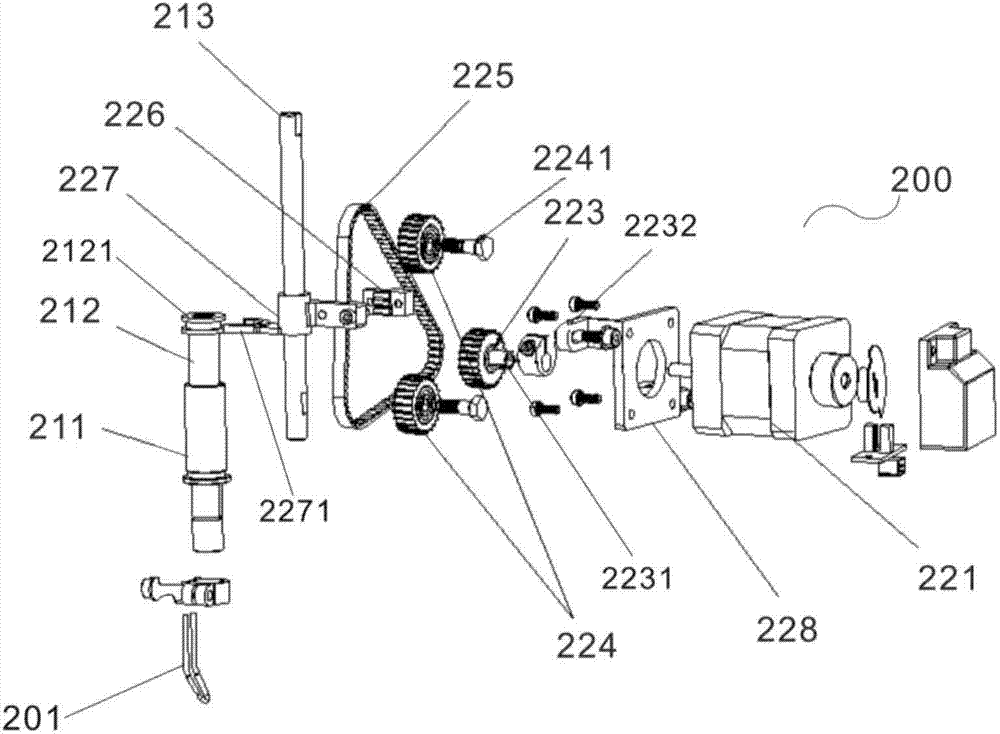

[0052] The presser foot mechanism 200 includes a presser foot 201 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com