Automatic hole making device of robot and machining method

An automatic and robotic technology, applied in manufacturing tools, other manufacturing equipment/tools, manipulators, etc., can solve problems such as inability to realize automatic positioning, large system volume and weight, lack of hole position detection and normal alignment units, etc. , to achieve the effects of simple structure, simplified device structure and good developability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

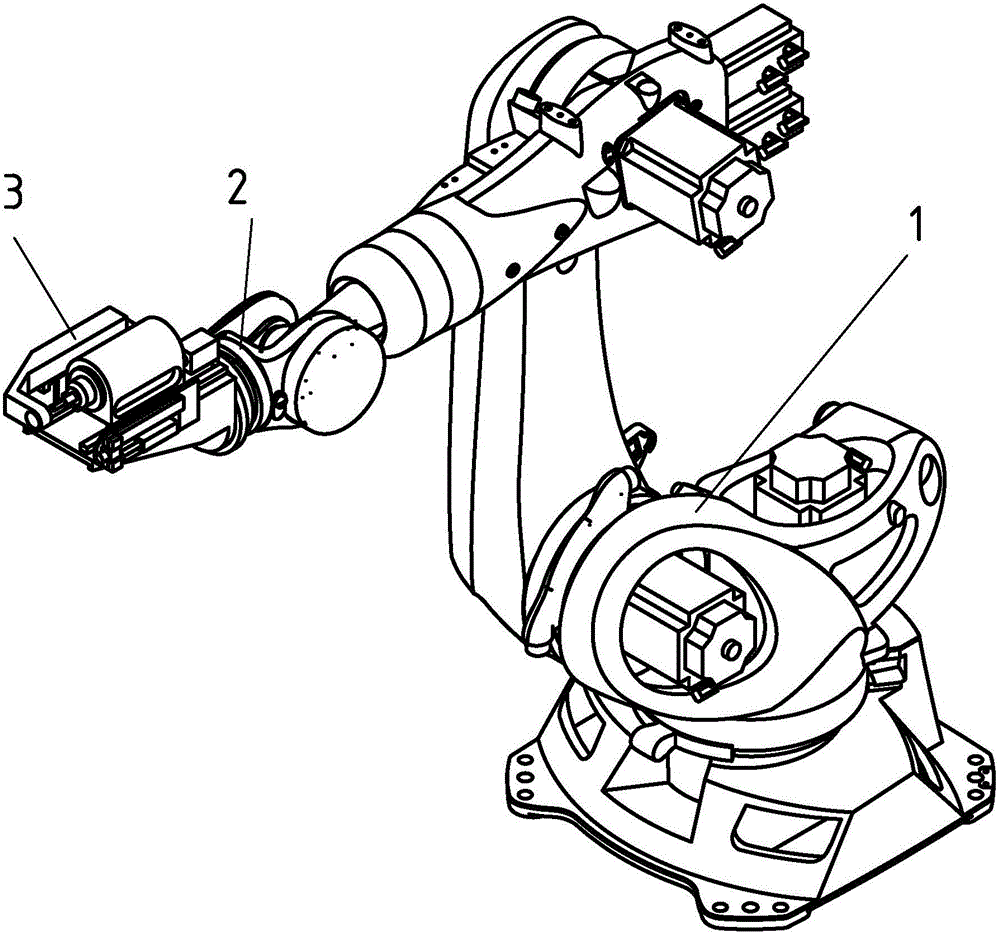

[0046] like Figure 1-Figure 7 As shown, a robot automatic hole-making device includes a six-axis serial robot arm 1, a mechanical arm end rotation mechanism 2 and an automatic hole-making end effector 3, and the six-axis serial robot arm 1 passes through the robot arm end rotation mechanism 2 is connected with the automatic hole making end effector 3,

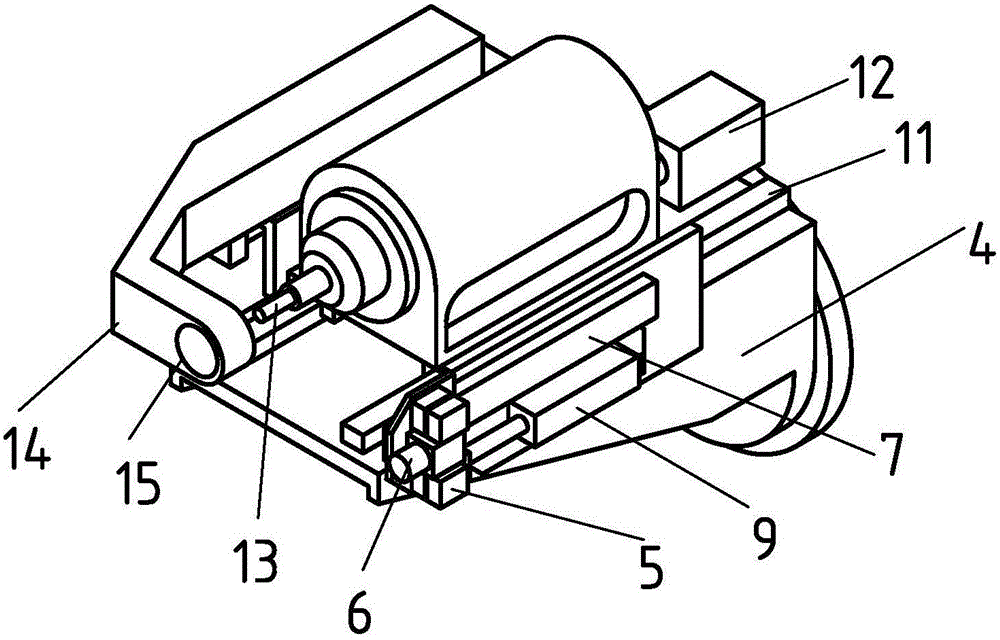

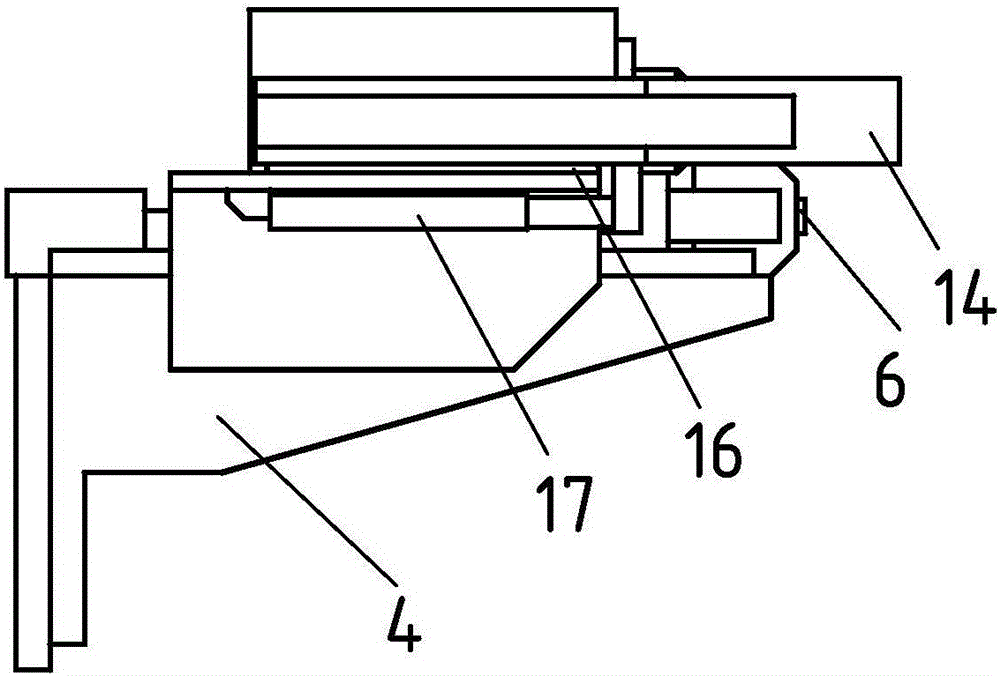

[0047] The automatic hole-making end effector 3 includes an automatic positioning and alignment module, a hole-making module, a pressure foot module and a frame 4,

[0048] The automatic positioning and correcting module includes four laser displacement sensors 5 that are centrally symmetrical and a CCD camera 6 located on the symmetrical center of the four laser displacement sensors 5, and the automatic positioning and correcting module is connected with the linear guide rail I7 The frame 4 is connected, the linear guide rail I7 is parallel to the rotation axis 8 of the rotating mechanism at the end of the mechanical arm, an...

Embodiment 2

[0059] like Figure 8-Figure 15 As shown, a robot automatic hole-making device includes a six-axis serial robot arm 1`, a mechanical arm end rotation mechanism 2` and an automatic hole-making end effector 3`, and the six-axis serial robot arm 1` passes through the mechanical The arm end rotation mechanism 2` is connected with the automatic hole-making end effector 3`,

[0060] The automatic hole making end effector 3` includes an automatic positioning and alignment module, a hole making module, a pressure foot module and a frame 4`,

[0061] The automatic positioning and correcting module includes four laser displacement sensors 5' that are centrally symmetrical and a CCD camera 6' located on the symmetrical center of the four laser displacement sensors 5', and the automatic positioning and correcting module passes through the linear guide rail I7' is connected to the frame 4', the linear guide rail I7' is parallel to the rotation axis 8' of the end rotation mechanism of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com