Automatic presser foot lifting and backward and forward sewing device of sewing machine and sewing machine

A presser foot lifting and sewing machine technology, which is applied in the field of industrial sewing equipment components, can solve the problems of high labor cost, low production efficiency, unsatisfactory, etc., and achieve the effect of simple and compact structure, convenient installation and maintenance, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

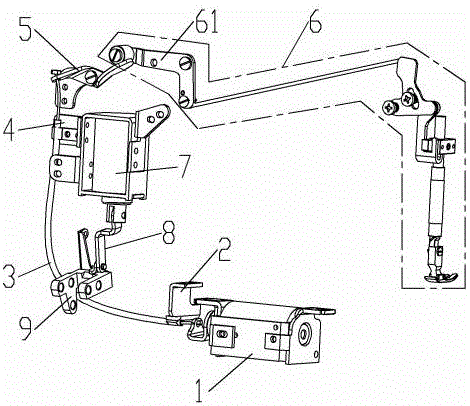

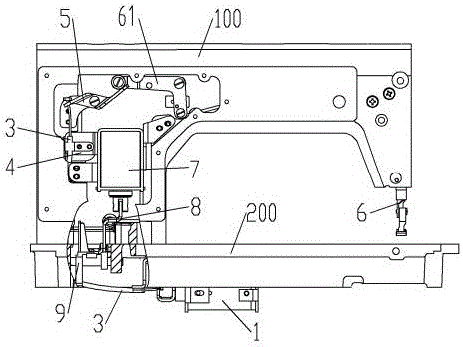

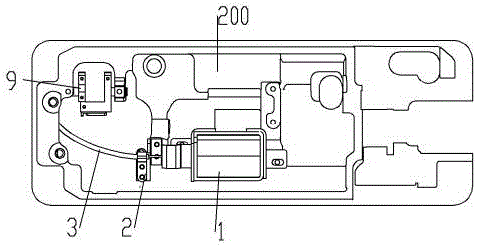

[0027] Such as Figure 1 to Figure 3 As shown, the automatic presser foot lifter and reverse sewing device of the sewing machine of the present invention includes a presser foot lifter driver 1, which is fixedly installed on the base plate 200, and a presser foot lifter driver 1 has a reciprocating motion along a straight line. Straight bar; the drawstring assembly 3 is composed of a drawstring cover and a stay rope, the stay rope can slide flexibly in the drawstring cover, the two ends of the drawstring cover are respectively fixed on the lower bracket 2 and the upper bracket 4, and the two ends of the stay rope are respectively It is connected with the straight rod of the presser foot driver 1 and one end of the swing rod 5; the swing rod 5 is connected to the machine head 100 and can swing around the swing center; It swings around the center of the pendulum shaft to drive the presser foot lifting rear lever 61 of the presser foot lifting mechanism 6, so that the presser foo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com