Cloth thickness variety supervisory instrument of sewing machine

A change detection and sewing machine technology, which is applied to sewing machine components, program-controlled sewing machines, sewing machine ring mechanisms, etc., can solve the problems of increased number of parts and difficulty in correct detection, etc., to reduce the number of parts and realize small size The effect of softening and suppressing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0053] (Overall configuration of the embodiment)

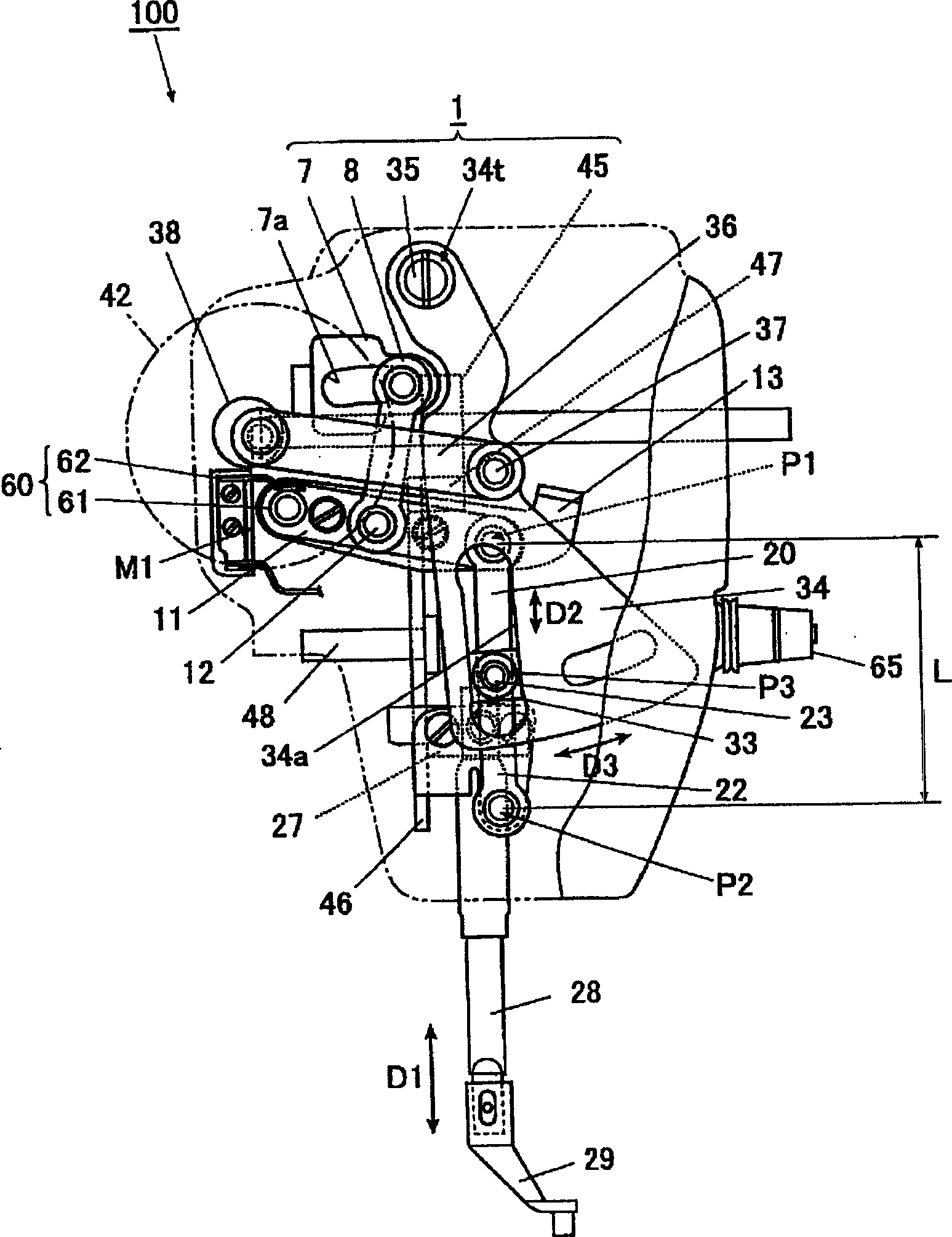

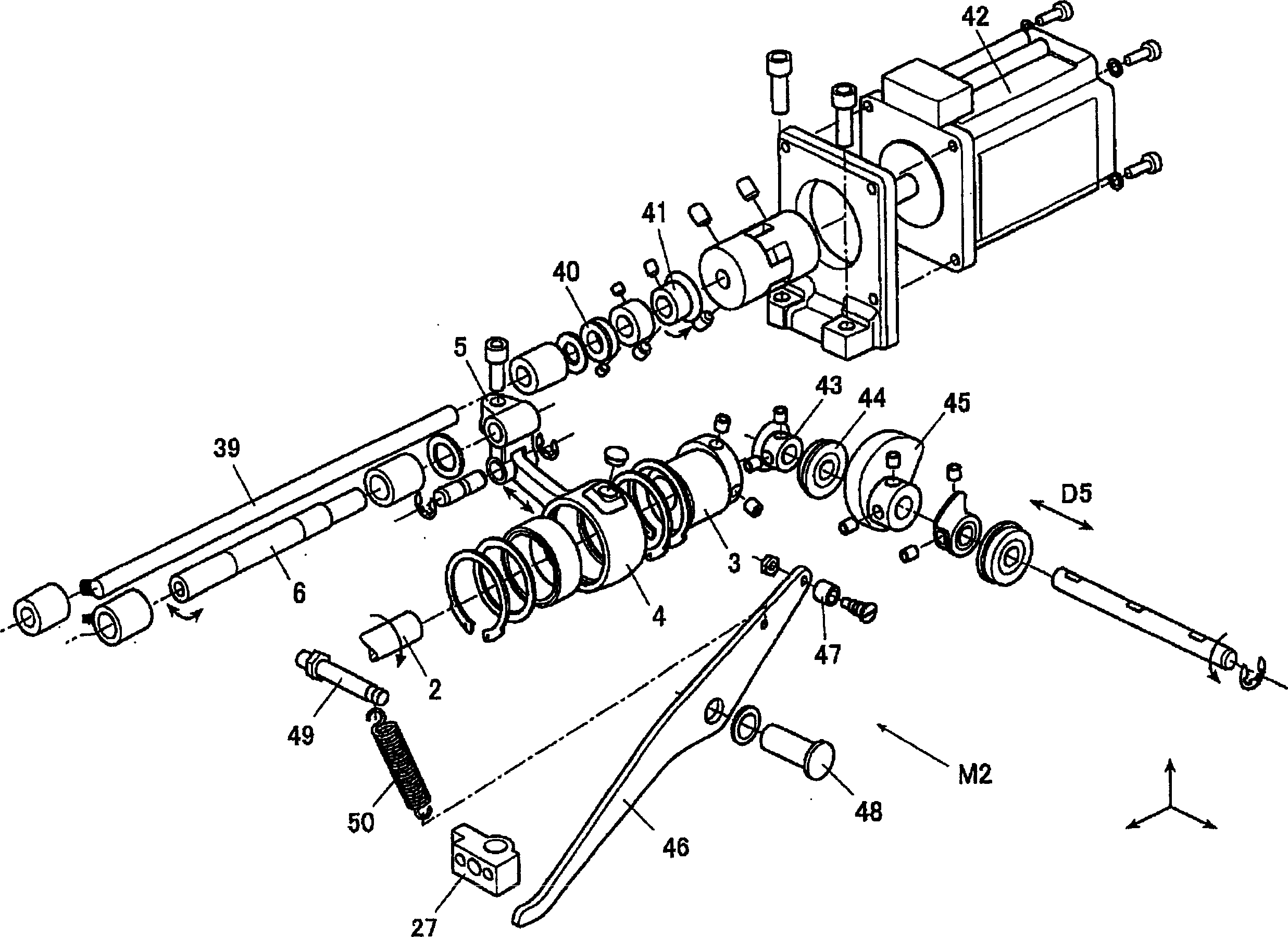

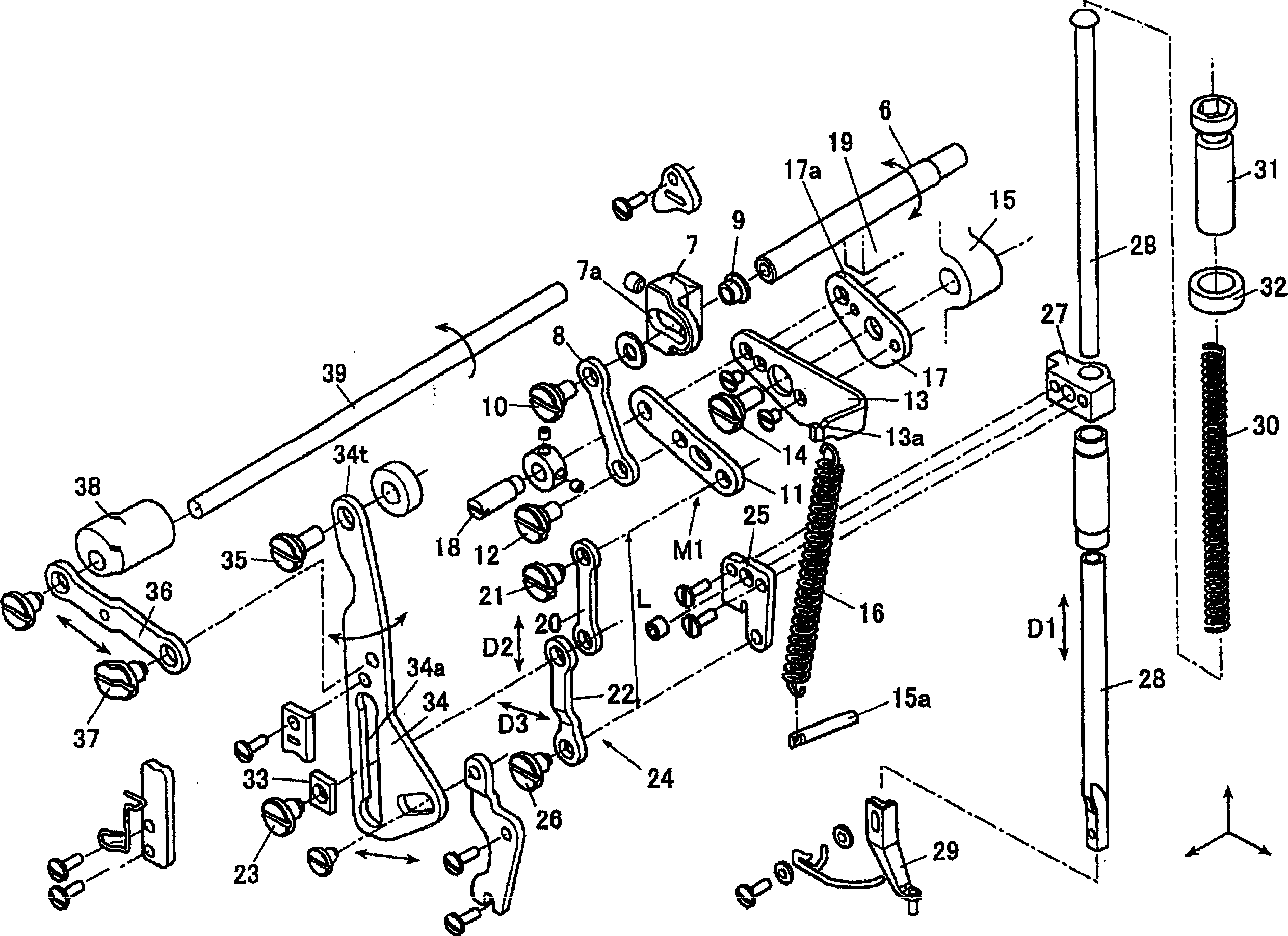

[0054] figure 1 It is a left side view of the main part of the sewing machine 100 in this embodiment viewed from the front side, figure 2 yes figure 1 An exploded perspective view of a part of the shown main part, image 3 yes figure 1 An exploded perspective view of the composition of the remaining part of the main part shown.

[0055] The sewing machine 100 has an unillustrated vertical movement mechanism for moving the needle up and down, a rotary hook mechanism for winding the lower thread and the suture thread inserted into the needle under the needle plate, a cloth holding mechanism as a moving mechanism, and a sewing machine. During sewing, the intermediate presser 29 moves back and forth up and down to press the object to be sewn to the needle plate side, and the intermediate presser as a thickness change detection device detects the thickness change of the fabric through the intermediate presser 29. The foot sen...

Embodiment approach 2

[0161] (summary of embodiment)

[0162] Below, based on Figure 10 ~ Figure 13 A second embodiment, 100A of sewing machines, will be described.

[0163] Such as Figure 10 As shown, the sewing machine 100A is newly equipped with an intermediate presser foot sensor 60A that can detect the amount of change in the up and down movement of the end of the first contact point 61 of the second link 11. The difference from the above sewing machine 100 is that the intermediate presser foot sensor 60A is used to The amount of change in thickness can be obtained when the cloth thickness changes, and motion control can be performed in consideration of the amount of thickness change.

[0164] Only the intermediate presser controller 60A differs from the sewing machine 100 in configurations other than the processing content of motion control. Therefore, in the sewing machine 100A, the same configurations as those in the sewing machine 100 are assigned the same symbols, and only the differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com