Needle bar and thread hooking assembly of sewing machine

A combined device and sewing machine technology, which is applied in the direction of sewing machine components, sewing machine needle holders, sewing machine ring mechanisms, etc., can solve the problems of fixed stroke, unrealizable motion track, simple needle bar motion track, etc., and achieve the goal of increasing complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

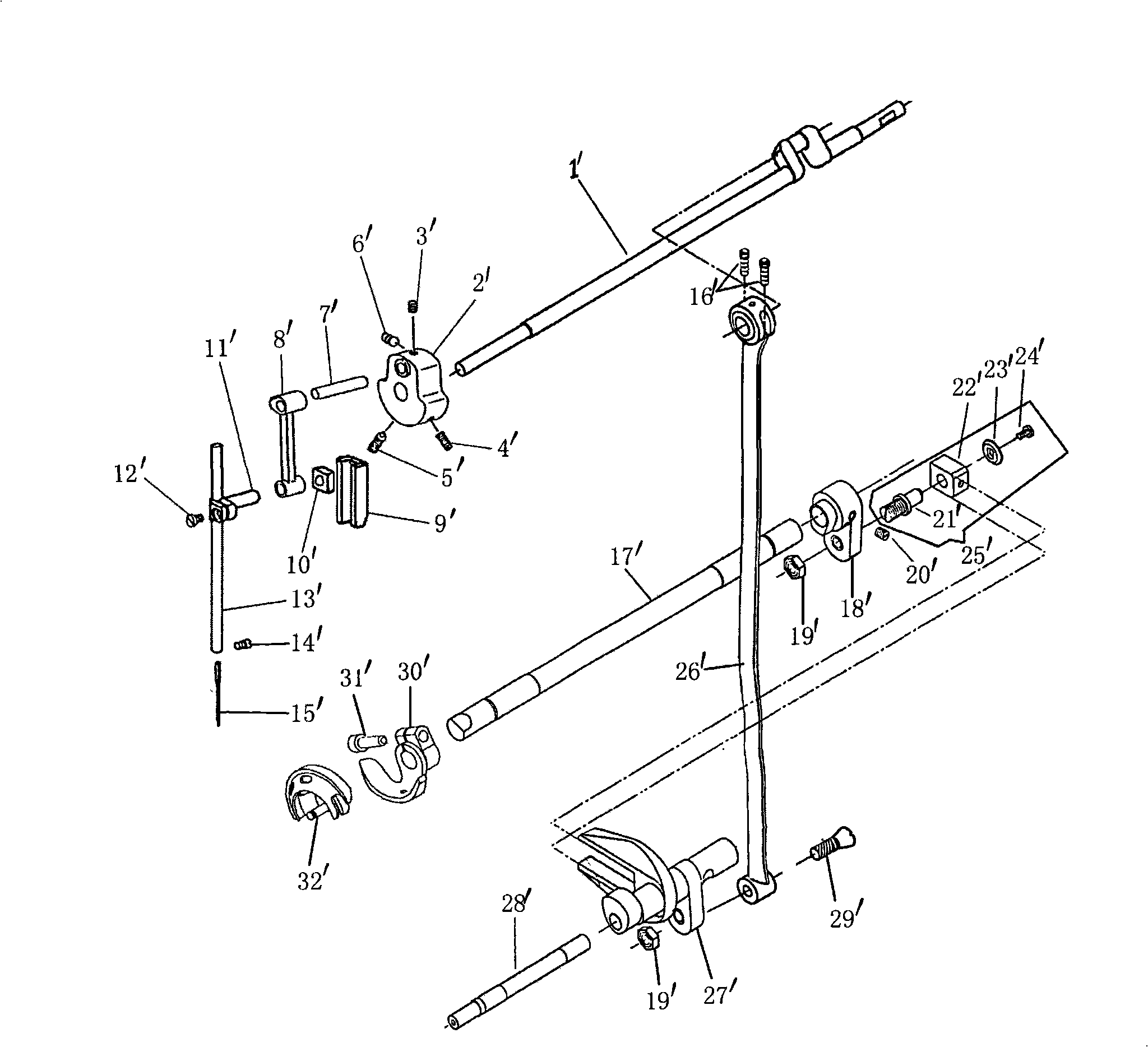

[0044] Below in conjunction with accompanying drawing, the shuttle swing mechanism of the novel sewing machine and the needle bar stabbing material and its combined mode are illustrated.

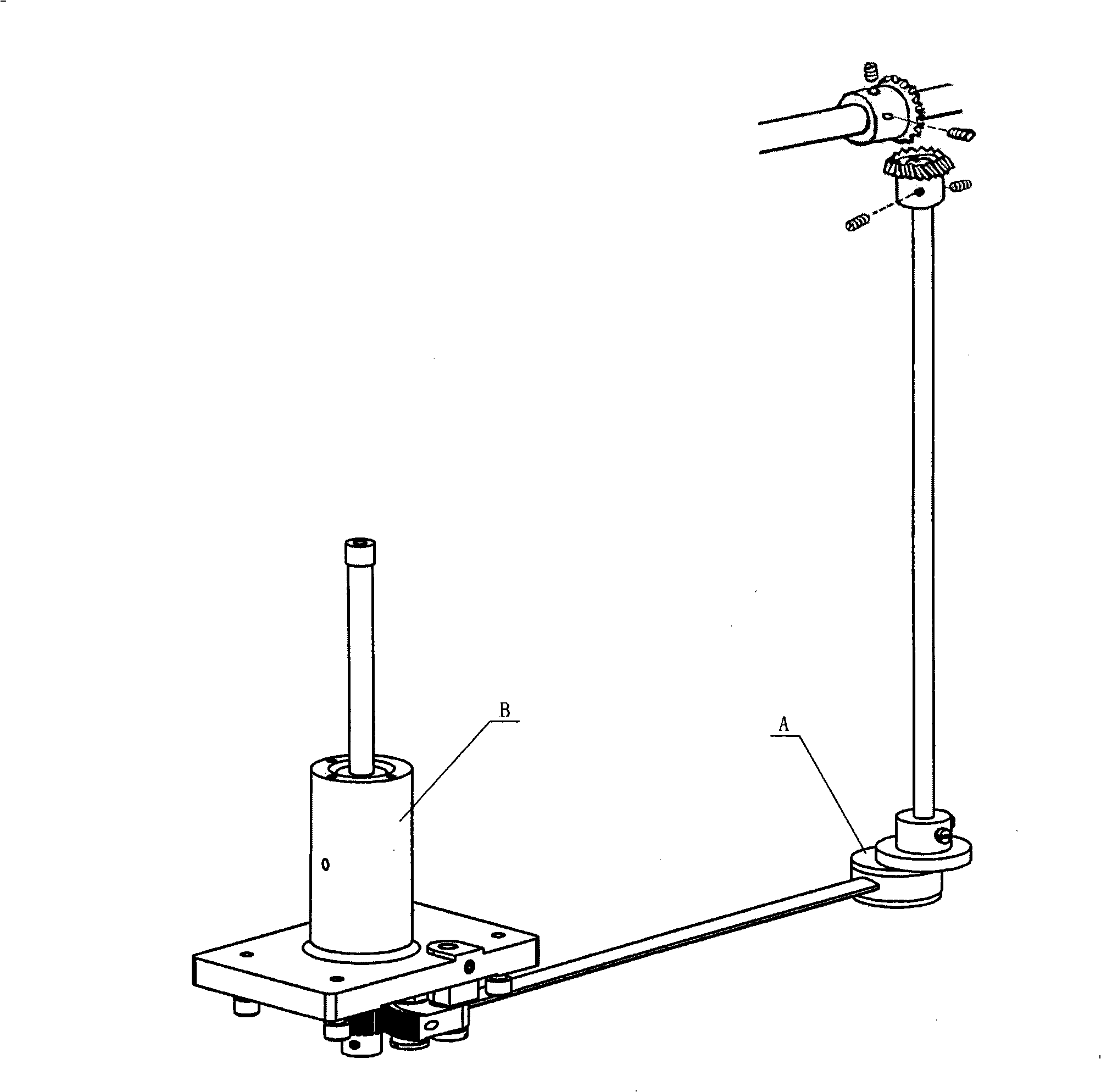

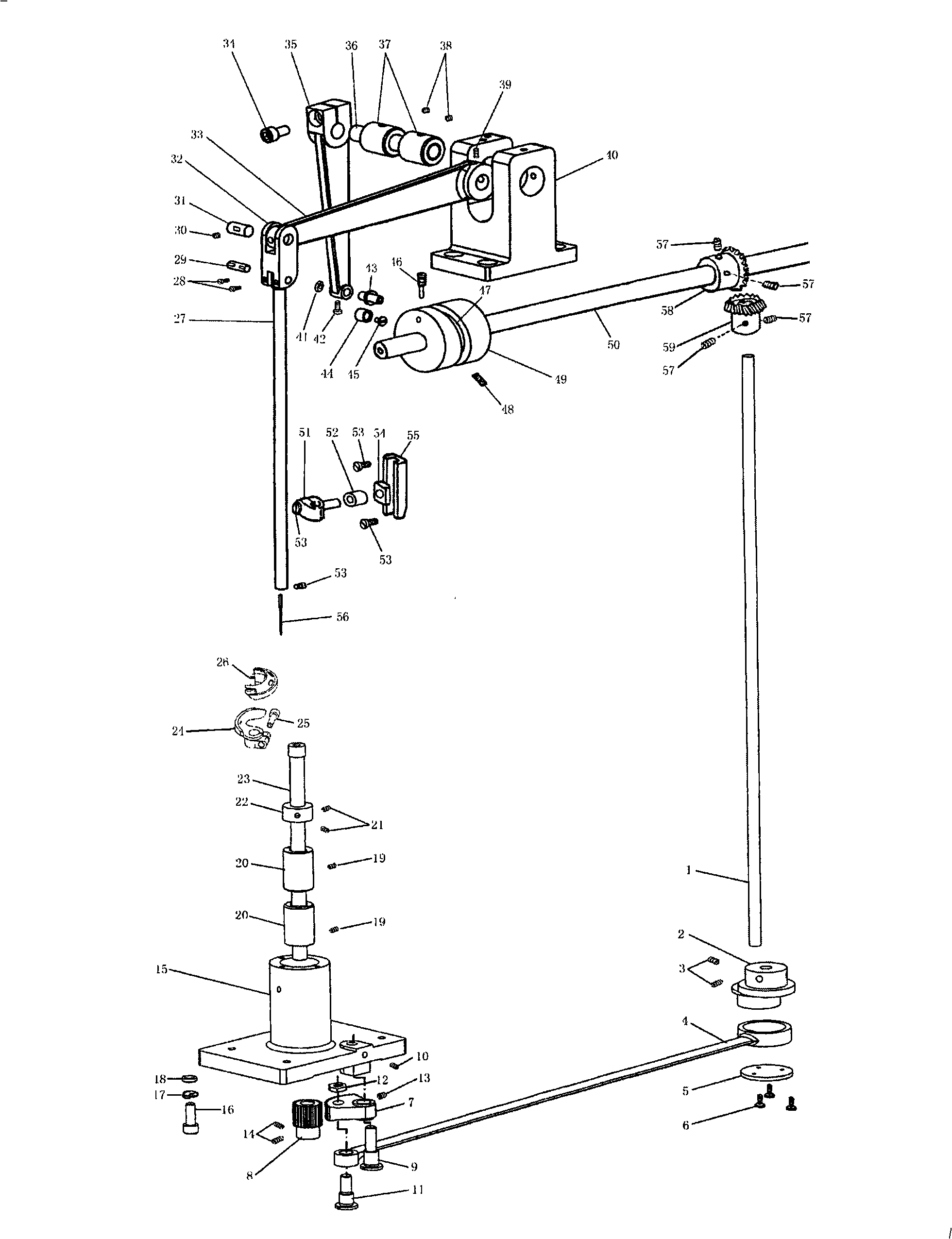

[0045] refer to figure 2 , image 3 Structure and mechanism transmission of the present invention are further described as follows:

[0046] The stabbing and hooking combination device of the sewing machine includes a shuttle hooking mechanism and a stabbing mechanism; it is characterized in that:

[0047] The crank assembly A includes a vertical shaft 1, a hook crank 2, a long connecting rod 4, a sector gear 7, a pinion 8, an upper shaft gear 58, and a vertical shaft gear 59. Wherein the upper shaft gear 58 and the vertical shaft gear 59 keep meshing, the upper end of the vertical shaft 1 is fixed on the vertical shaft gear 59 via a screw 57, and the lower end of the vertical shaft 1 is fixed in the center hole on the upper part of the hook crank 2 via a screw 3; One end of the long con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com