Sewing method of double-embedded-wire pocket

A technology of double inlays and pockets is applied in the direction of sewing tools, clothing, clothing, etc., which can solve the problems of time-consuming, difficult production, and high skill requirements for sewing workers, so as to reduce the difficulty of the process, improve the sewing speed, The effect of improving sewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

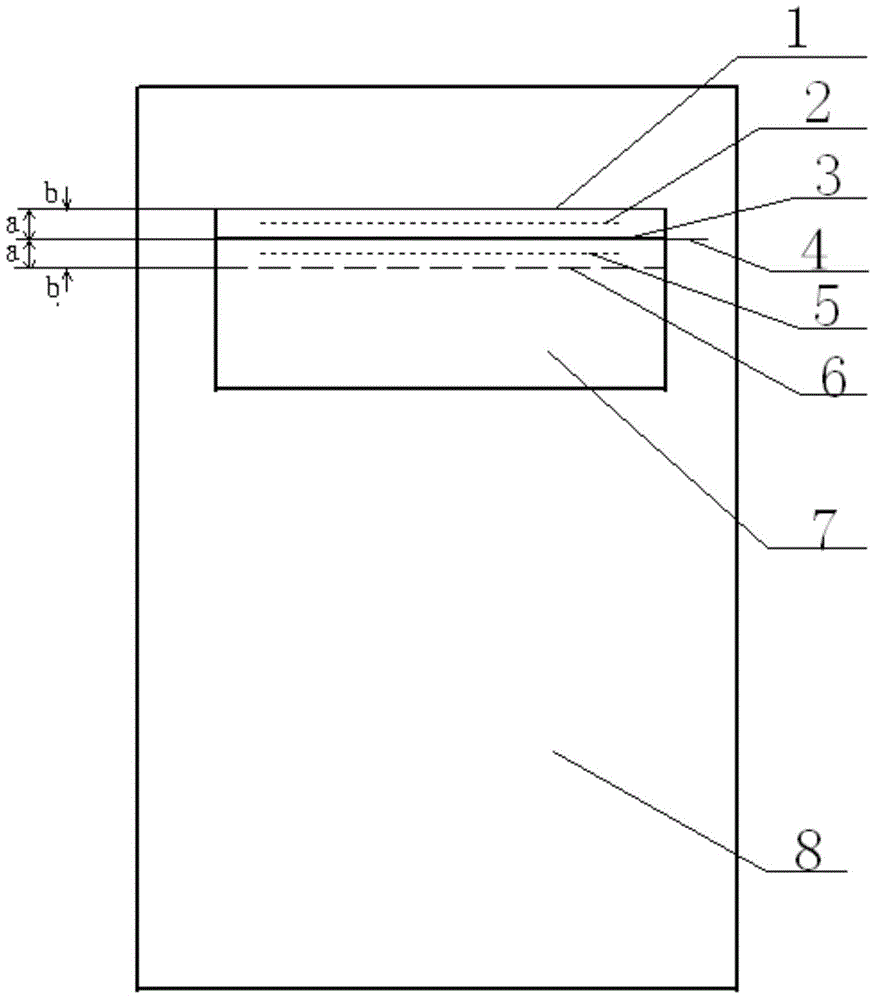

[0023] Such as figure 1 As shown, a sewing method of a double welt pocket, including

[0024] Step 1) Cutting and gluing

[0025] Cut a piece of seam cloth 7, the length dimension of the seam cloth 7 along the extending direction of the pocket mouth is greater than the length of the pocket mouth; the seam cloth 7 is bonded and the back side of the pocket position of the clothes piece 8 is bonded at the same time. lining;

[0026] Step 2) Sewing two ruled lines on the ruled cloth 7;

[0027] Step 3) sewing the fillet;

[0028] In step 1), draw the pocket center line 4 at the front pocket position of the garment body 8 as a positioning line; fold down the raw edge 3 on the top of the seam cloth 7 by the first distance a and fold it Partly buckled and ironed to form the first hemming line 1, and then based on the first hemming line 1, the second distance b is folded downwards and the folded part is buckled and ironed to form the second hemming line 6. The length of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com