Automatic sewing machine

A sewing machine and automatic technology, applied to program-controlled sewing machines, sewing machine components, sewing machine needle seats, etc., can solve the problems of product quality degradation, damage to fabric fibers, damage to needle points, etc., and achieve the effect of improving sewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

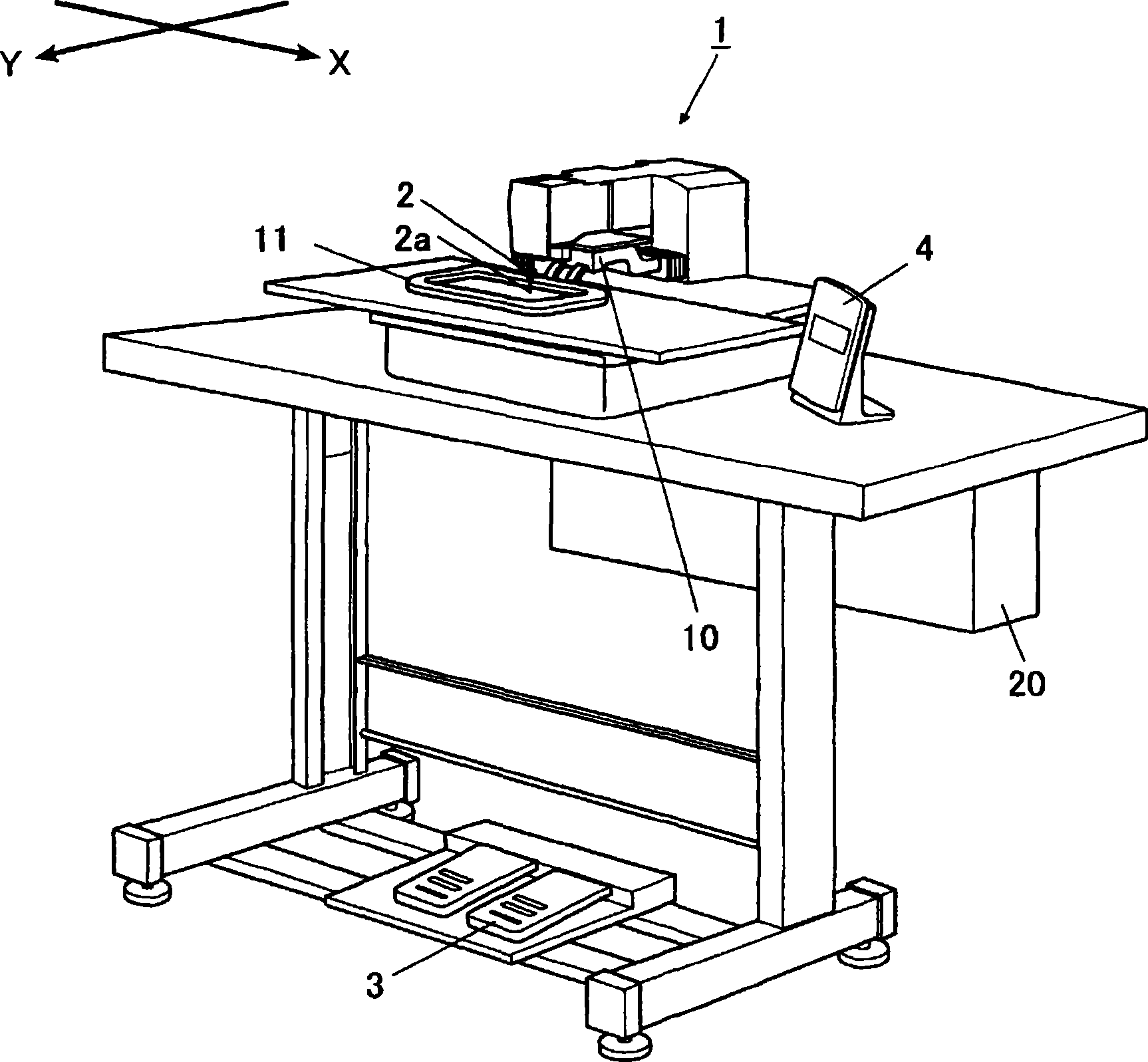

[0033] (Overall structure of the sewing machine of the present invention)

[0034] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0035] The sewing machine 1 according to the present invention is an automatic sewing sewing machine provided with a moving device 10 movable along a horizontal plane perpendicular to the vertical movement direction relative to the vertical movement of the needle bar 2 to which the sewing needle 2a is attached. , hold the sewing product and carry out sewing.

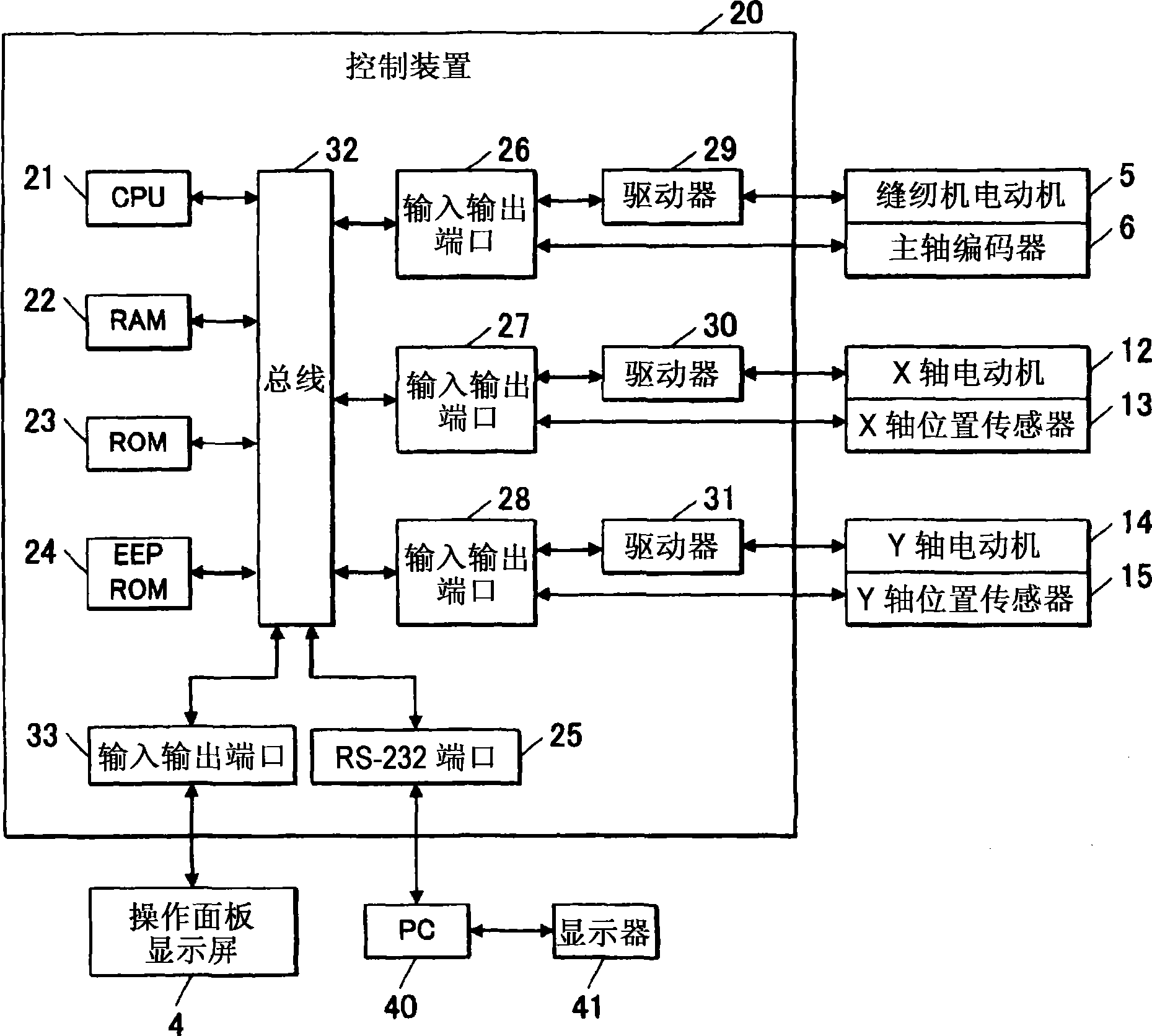

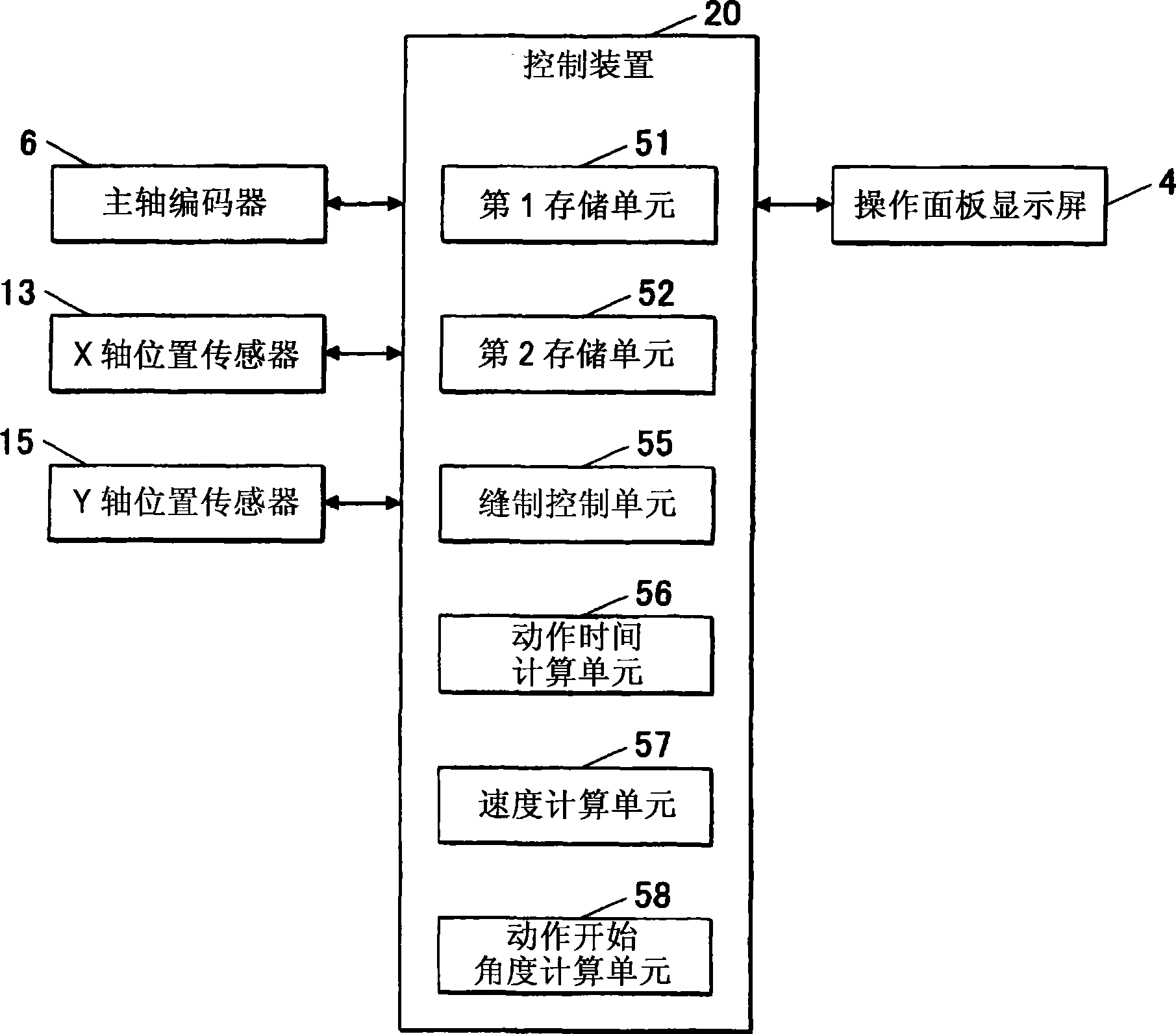

[0036] figure 1 It is a perspective view showing the structure of the sewing machine 1 according to the present invention. figure 2 It is a block diagram showing the control device 20 and various configurations connected to the control device 20 .

[0037] Such as figure 1 as well as figure 2 As shown, the sewing machine 1 has: the needle bar 2, which is arranged on the lower surface portion of the arm of the sewing machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com