Sewing machine

A sewing machine and feeding mechanism technology, applied to sewing machine components, sewing machines, sewing machine control devices, etc., can solve problems such as difficult sewing, easy swinging of the traveling direction to the left or right, and inability to cope with changes in the curvature of the curve, etc. Achieve the effect of realizing sewing quality and stable traveling direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] [Overall structure of sewing machine]

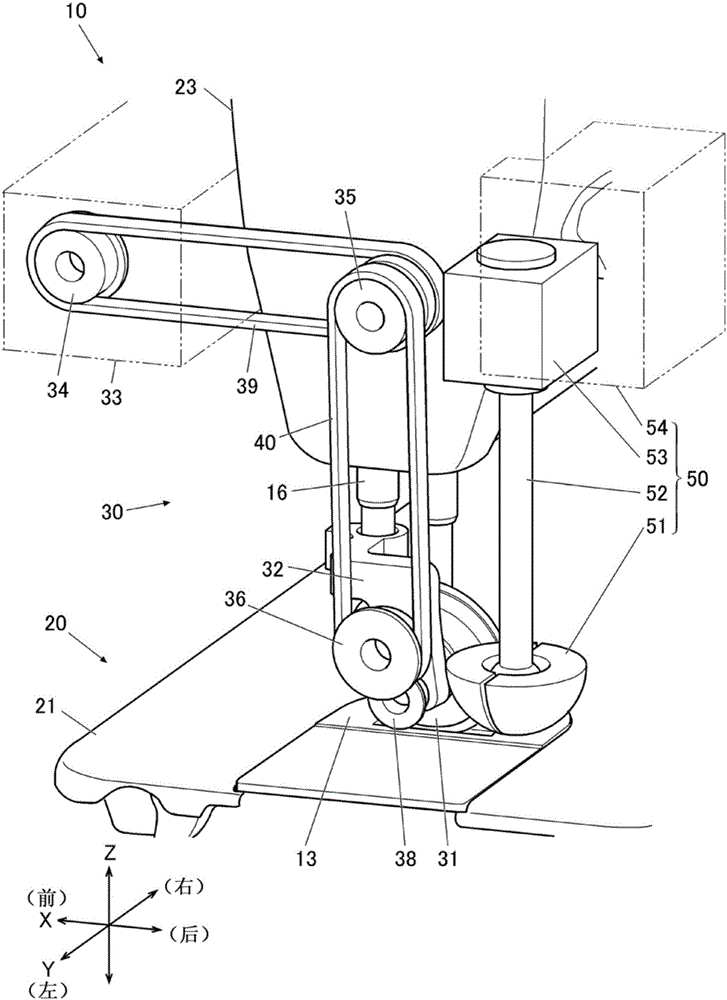

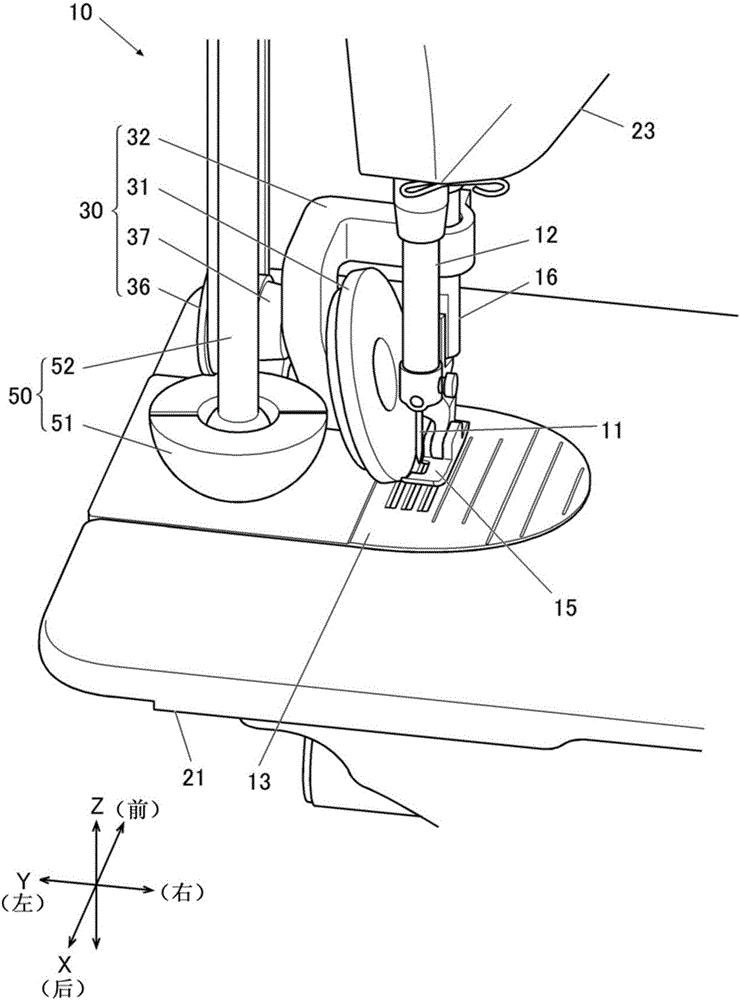

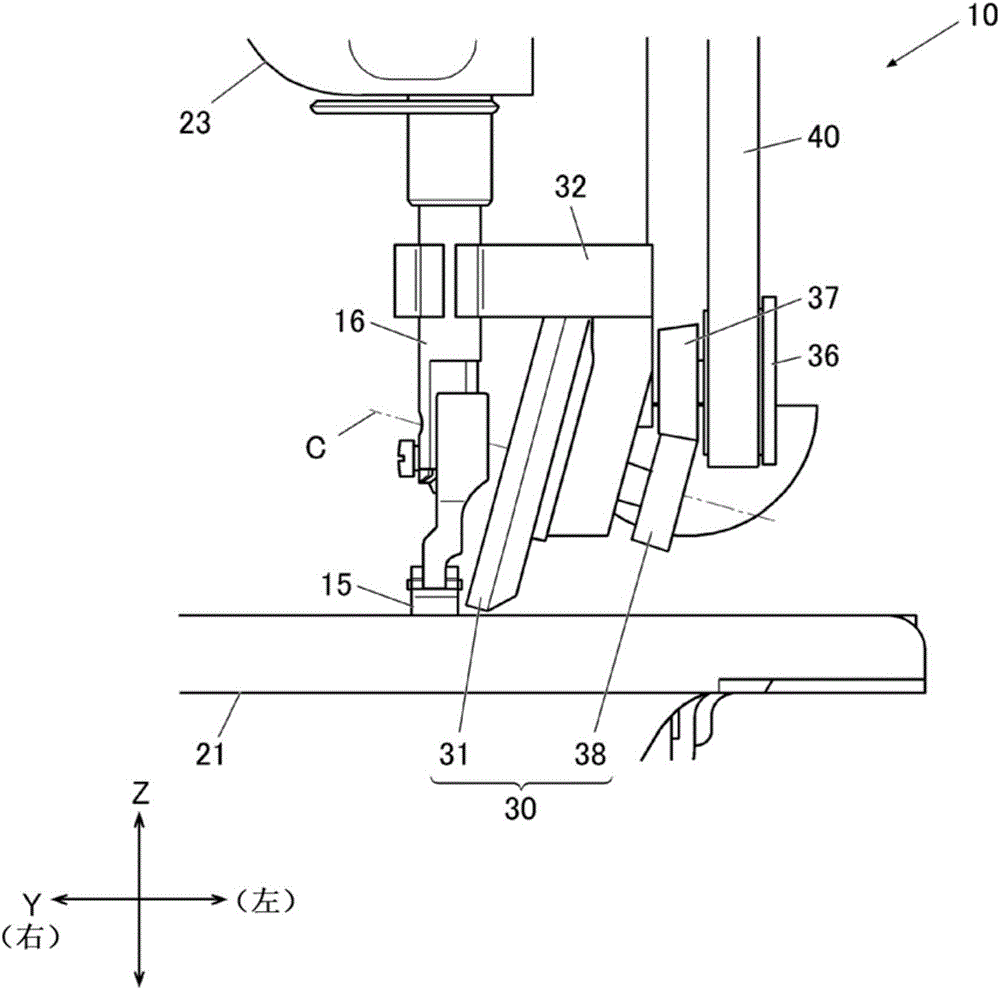

[0064] Below, based on Figure 1 to Figure 7 , the sewing machine 10 as an embodiment of the present invention will be described.

[0065] figure 1 It is a perspective view omitting a part of the structure of the sewing machine 10, figure 2 It is an oblique view viewed from another direction.

[0066] The above-mentioned sewing machine 10 is equipped with: a needle bar 12, which holds the sewing needle 11 at the lower end; a needle bar vertical movement mechanism (not shown), which moves the needle bar 12 up and down; The upper thread of the needle 11 is caught and entangled with the lower thread; the main feed mechanism (not shown in the figure) makes the feed teeth enter and exit from the opening of the needle plate 13, and advances the sewing object in a predetermined straight direction. Give; the first feeding mechanism 30, which is adjacent to the needle drop position of the needle plate 13, that is, the needle hole, car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com