Automatic folding and sewing equipment of labels

A label, automatic technology, applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of high operation difficulty, low efficiency, time-consuming folding and sewing, etc., and achieve high sewing quality and high folding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

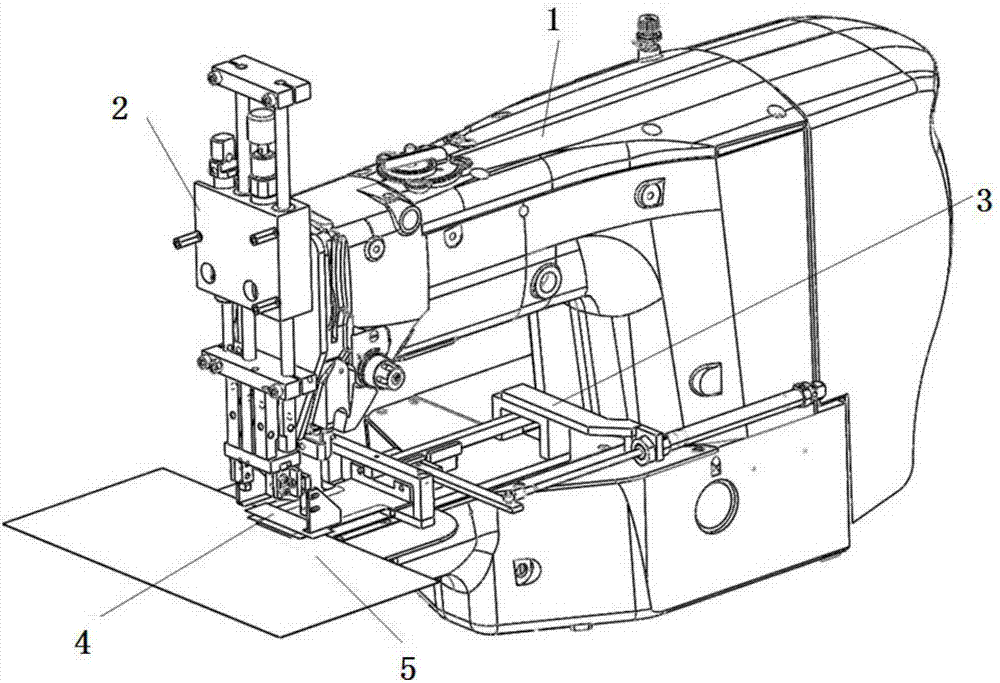

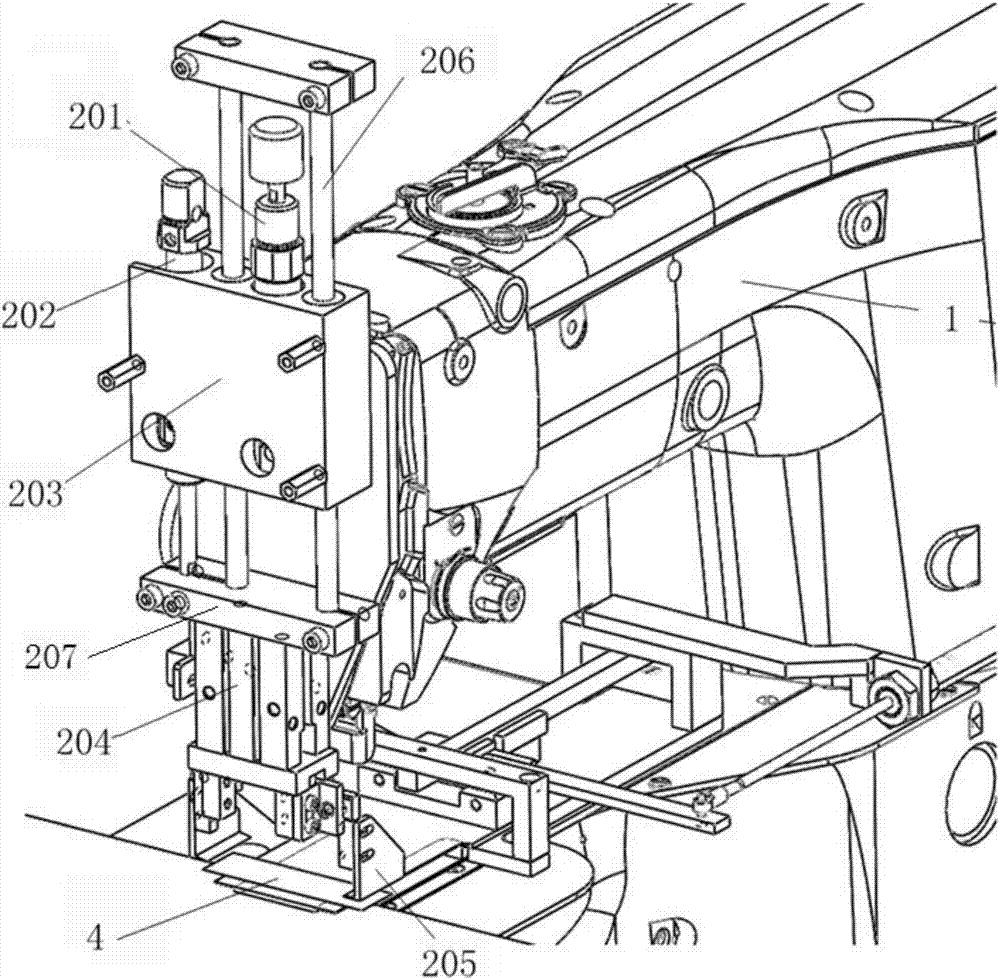

[0021] A label automatic folding and sewing equipment, such as figure 1 As shown, it includes an industrial sewing machine 1, a folding mechanism 2 and a material supporting mechanism 3. The folding mechanism 2 is arranged on the head of the industrial sewing machine 1, and the material supporting mechanism 3 is arranged at the lower part of the industrial sewing machine 1 for sending the label 4 to the folding mechanism 2. The folding mechanism 2 folds the two ends of the label sent by the material holding mechanism 3 inwardly, and then the industrial sewing machine 1 sews the folded label 4 onto the cloth 5 .

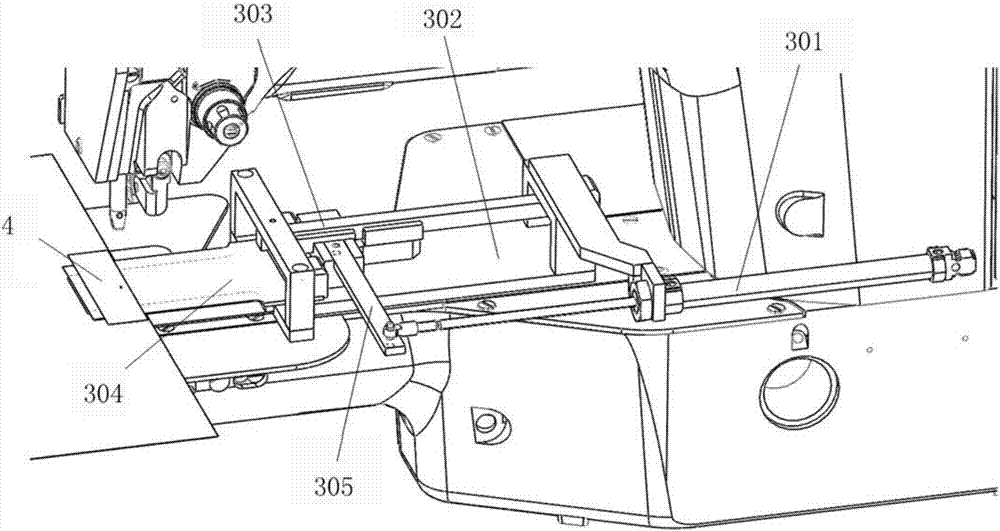

[0022] The structure of supporting structure 3 is as follows figure 2 As shown, the supporting mechanism base 302 is included, the supporting mechanism base 302 is provided with a supporting cylinder 301, the cylinder rod of the supporting cylinder 301 is connected with the connecting rod 305, and the connecting rod 305 is fixed on the label supporting plate 304, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com