A fully automatic pancake folding assembly line and its application

An assembly line, fully automatic technology, applied in application, baking, preservation of baked products, etc., can solve the problems of inability to realize pancake streamlined treatment, cumbersome folding process, high damage rate of pancakes, achieve good market prospects, save labor, and produce low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

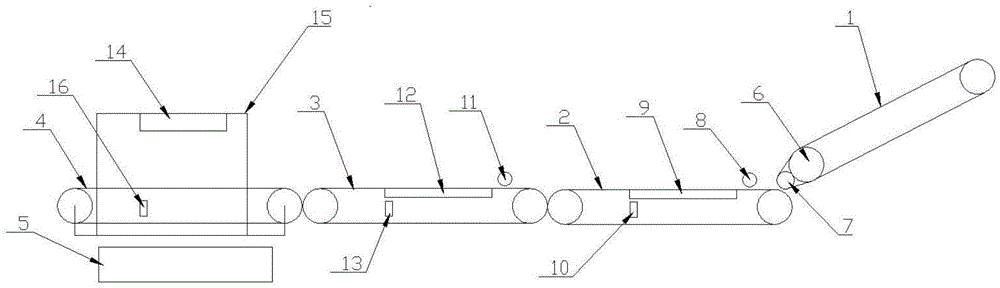

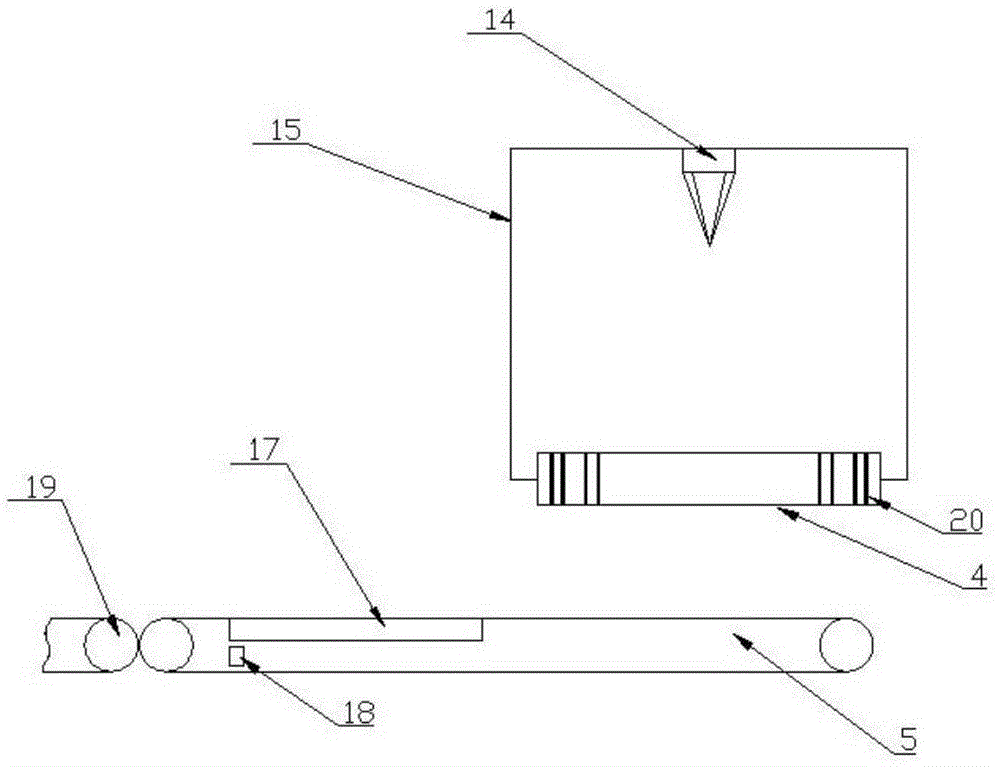

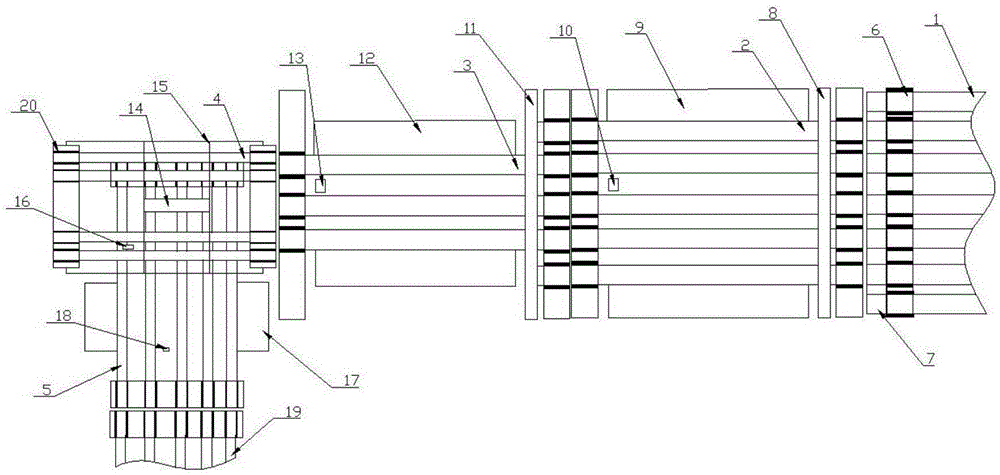

[0037] See attached Figure 1-4 , a fully automatic pancake folding assembly line, which consists of two conveying and folding lines, one horizontal and one vertical, wherein the horizontal conveying and folding line is composed of four-stage conveyor belts, sensors and folding devices; Composition of folding device;

[0038] The horizontal conveyor belt is composed of four independent and end-to-end conveyor belts with the same conveying direction, the first-level conveyor belt 1, the second-level conveyor belt 2, the third-level conveyor belt 3 and the fourth-level conveyor belt 4. Among them, the first-level conveyor belt 1 does not have a folding machine, and the second-level conveyor belt 2 There is a finale 8 at the upper end of the conveyor belt near one end of the first-level conveyor belt 1, and a folding machine 9 is arranged at the rear end of the finale shaft 8 along the conveying direction, and a sensor 10 is arranged at the end of the folding machine 9 towards th...

Embodiment 2

[0050] In order to make softened pancakes, a water spray device and electric heaters are installed on the primary conveyor belt. After the pancakes are sprayed with water, they are quickly heated by the electric heaters, the water vapor is atomized, and the pancakes soften quickly. In this embodiment, the primary conveyer belt is arranged horizontally, and a shower nozzle is arranged at the front end of the conveyer belt, and the electric heater ( Figure 6 ). In actual production, the electric heater power is 15kw. The effect of this embodiment is: after applying the pancake spray softening process, the pancake can be very thin, and the pancake with a diameter of about 900 mm weighs only 100-120 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com