Band tailoring sewing machine

A sewing machine and belt loop technology, which is applied in the direction of program-controlled sewing machines, sewing machine components, sewing equipment, etc., can solve the problem that the width cannot be arbitrarily determined, and achieve the effect of high design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] (Outline of sewing device)

[0046] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

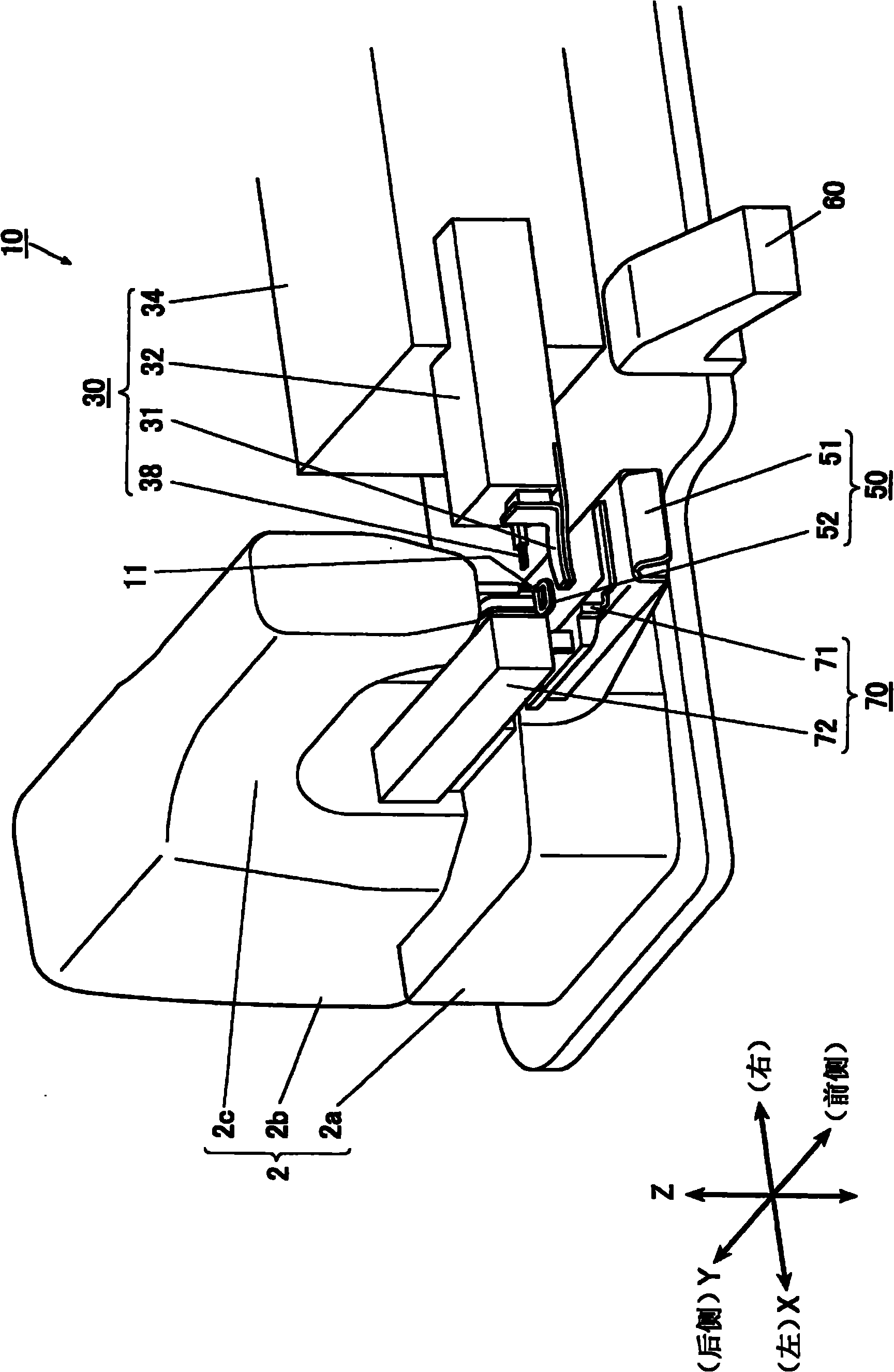

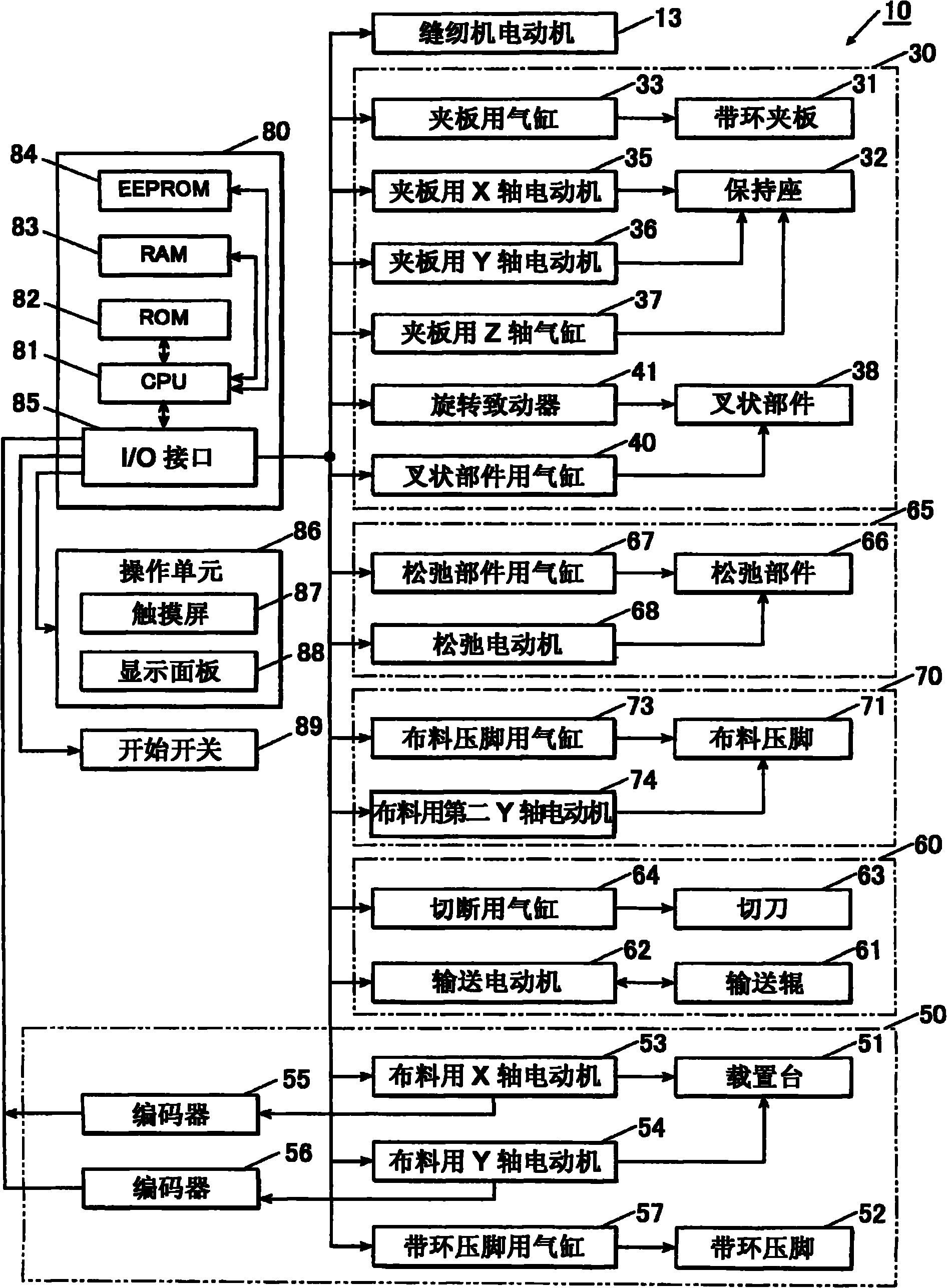

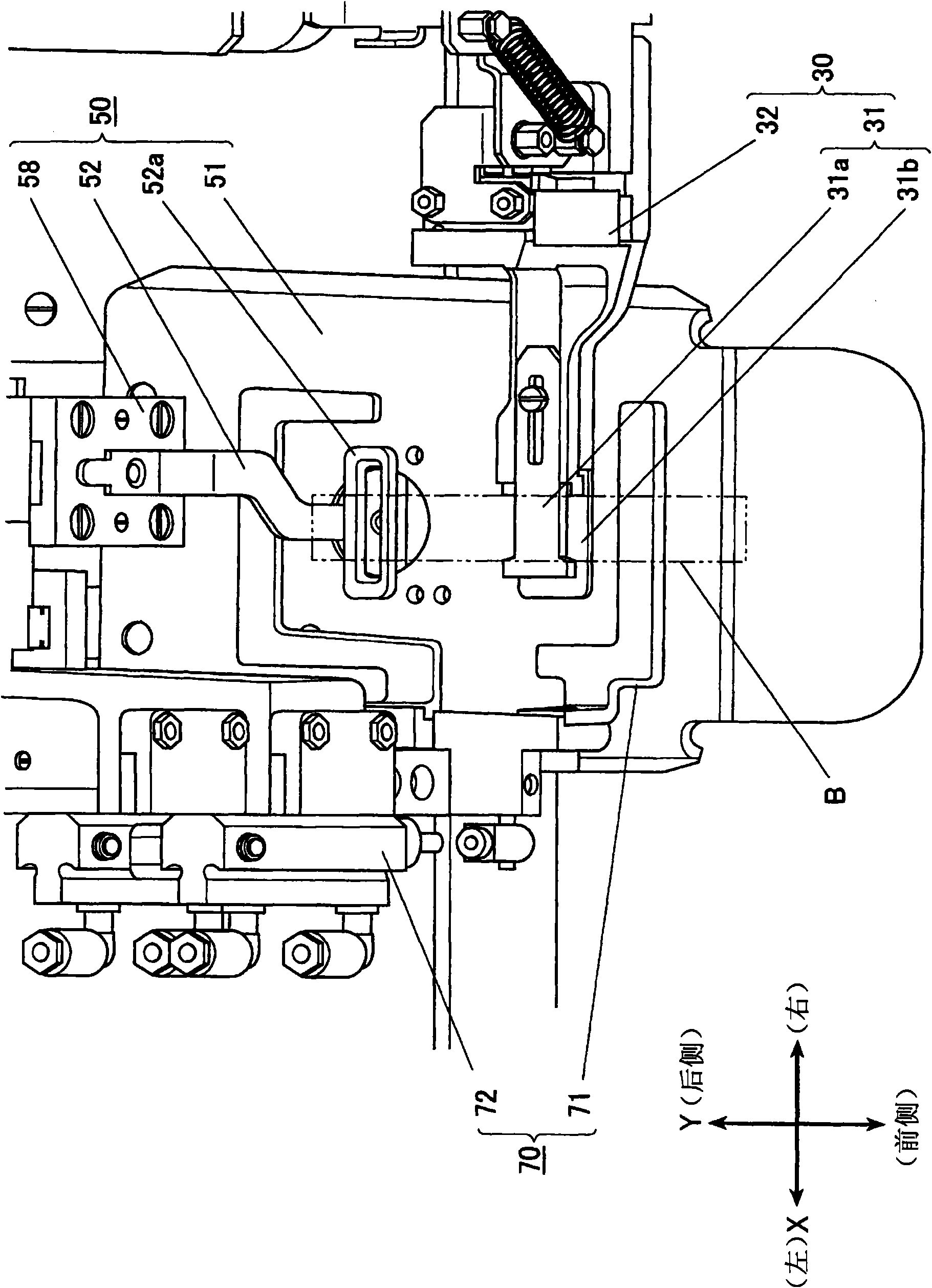

[0047] exist figure 1 , figure 2 , image 3 Among them, the belt loop sewing sewing machine 10 has: an unillustrated sewing needle up and down movement mechanism, which moves the sewing needle 11 up and down; a clamping mechanism 30, which has a belt loop splint 31, and the belt loop splint 31 is used for clamping The belt loop B in a predetermined direction; the belt loop supply mechanism 60, which supplies the belt loop B to the clamp mechanism 30; the belt loop presser mechanism 50, which has a mounting table for placing the cloth C for sewing the belt loop B 51, and the belt loop presser 52 that presses the belt loop B through the downward movement to the mounting table 51; the loosening mechanism 65, which has a loosening member 66 that loosens the ring portion of the belt loop B; the cloth presser foot mechanism 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com