Cloth automatic edge aligning device of sewing machine

A sewing machine and fabric technology, applied in sewing machine components, sewing equipment, cloth feeding mechanisms, etc., can solve the problems of affecting the quality of fabric sewing, insufficient detection accuracy, and failure to press the selvedge, and achieve high work efficiency and detection accuracy. High, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

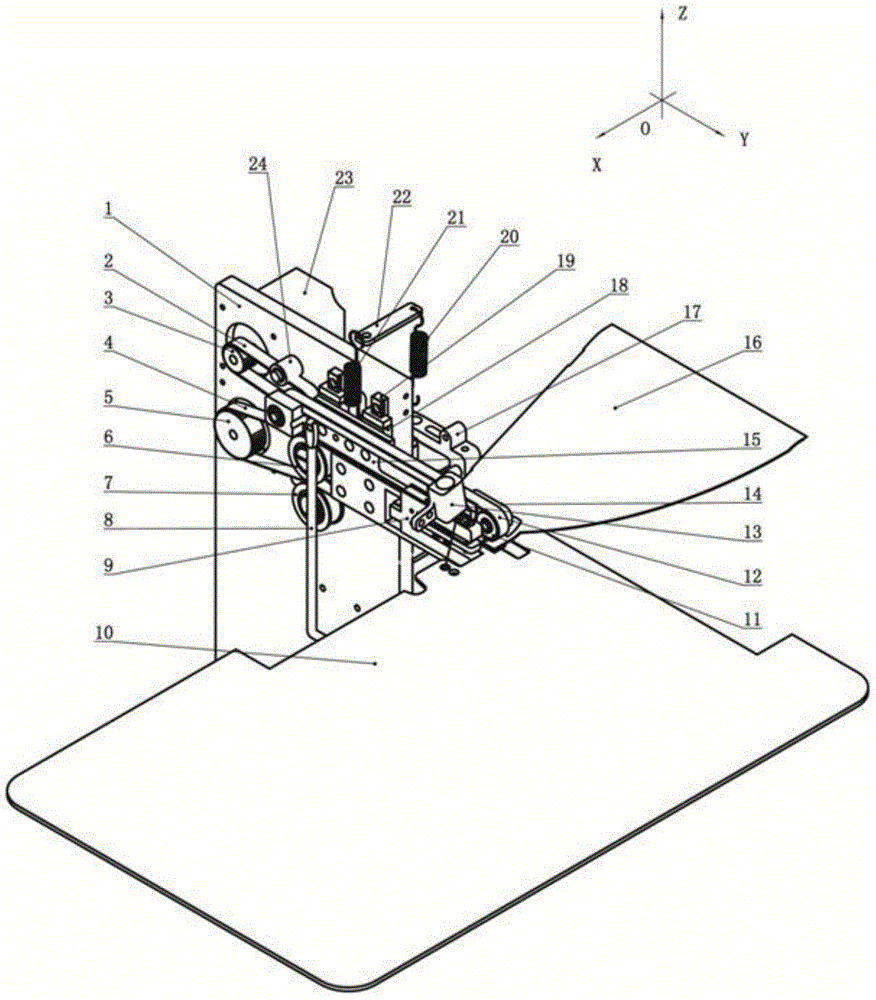

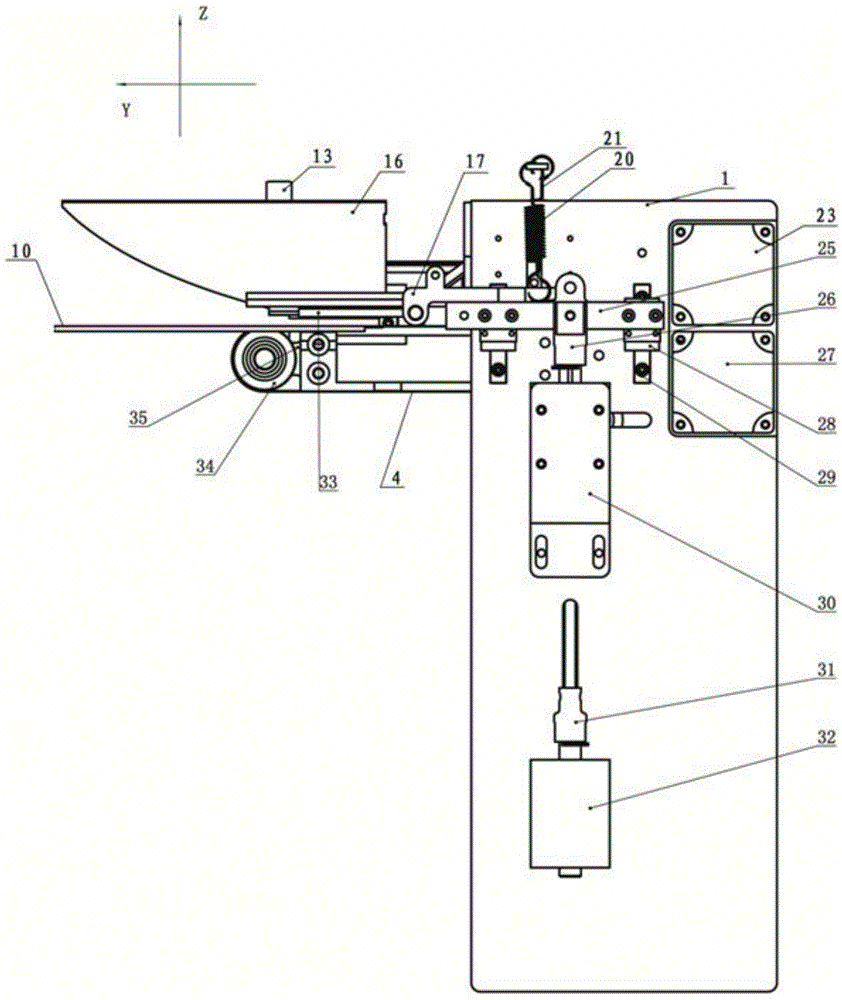

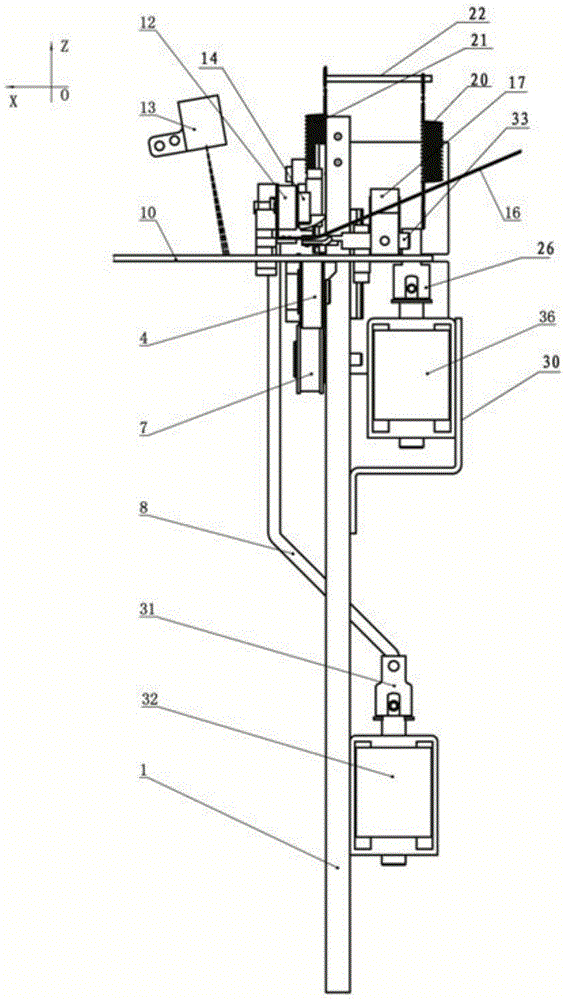

[0032] First introduce the main structure and work engineering of the sewing machine cloth automatic edge-aligning device of the present invention below:

[0033] An automatic edge detection and adjustment system includes a detection mechanism and an adjustment mechanism. The detection mechanism includes three sets of upper and lower sensors for detecting the position of the cloth edge. The upper and lower three sets of sensors are opposite-beam multi-point high-precision sensors, and their structures are respectively installed on the upper and lower sides of the middle PCB board to receive High-precision multi-point sensor; the middle layer PCB board is installed on the sensor outer frame, and fixed on the bracket by screws, and the corresponding holes of the upper layer and the lower layer bracket and the middle layer sensor are used to install the light source and the wave mirror pattern lens, The corrugated lens is to shape the light source into a linear light source requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com