Automatic recording system for running time of production line device

A technology of production line equipment and running time, applied in metal processing equipment, registration/indicating machine production, comprehensive factory control, etc. Data cannot be further used and shared to achieve the effect of reducing manual labor, improving real-time and authenticity, and producing data in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

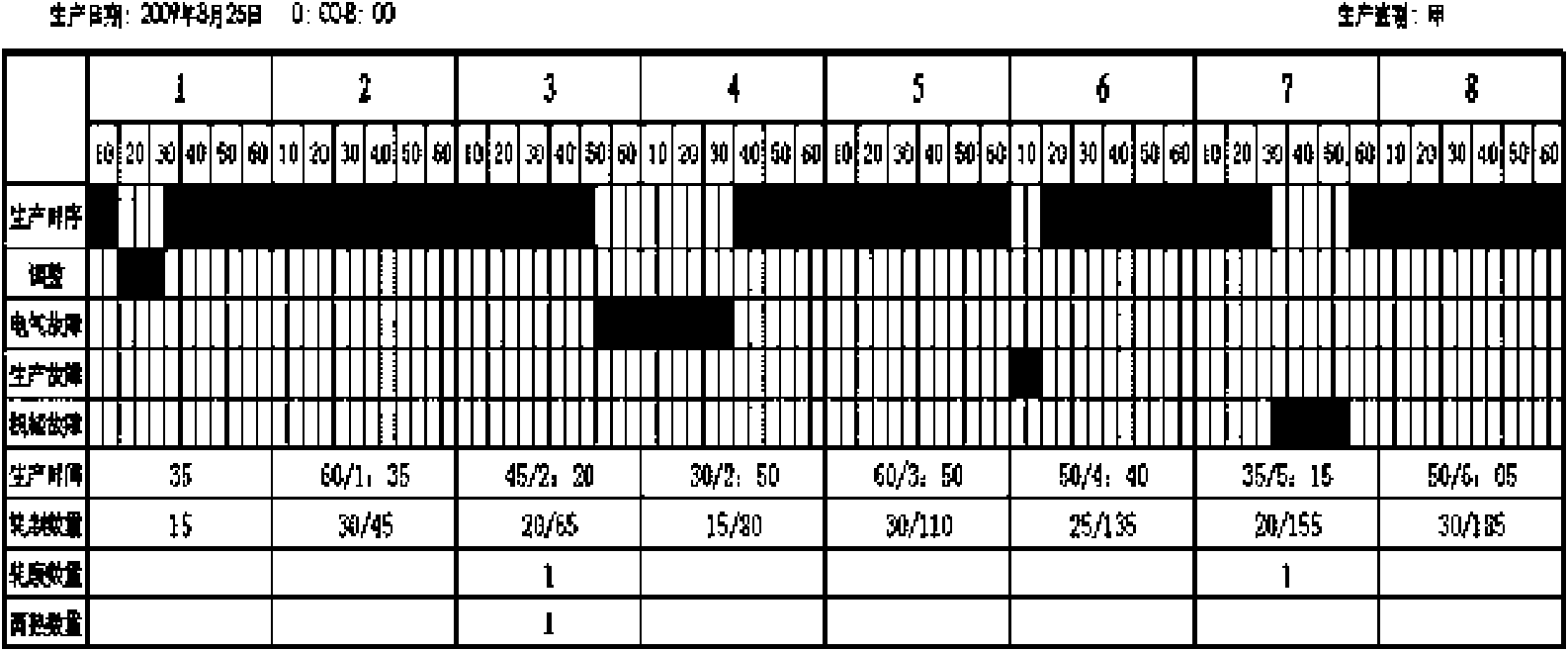

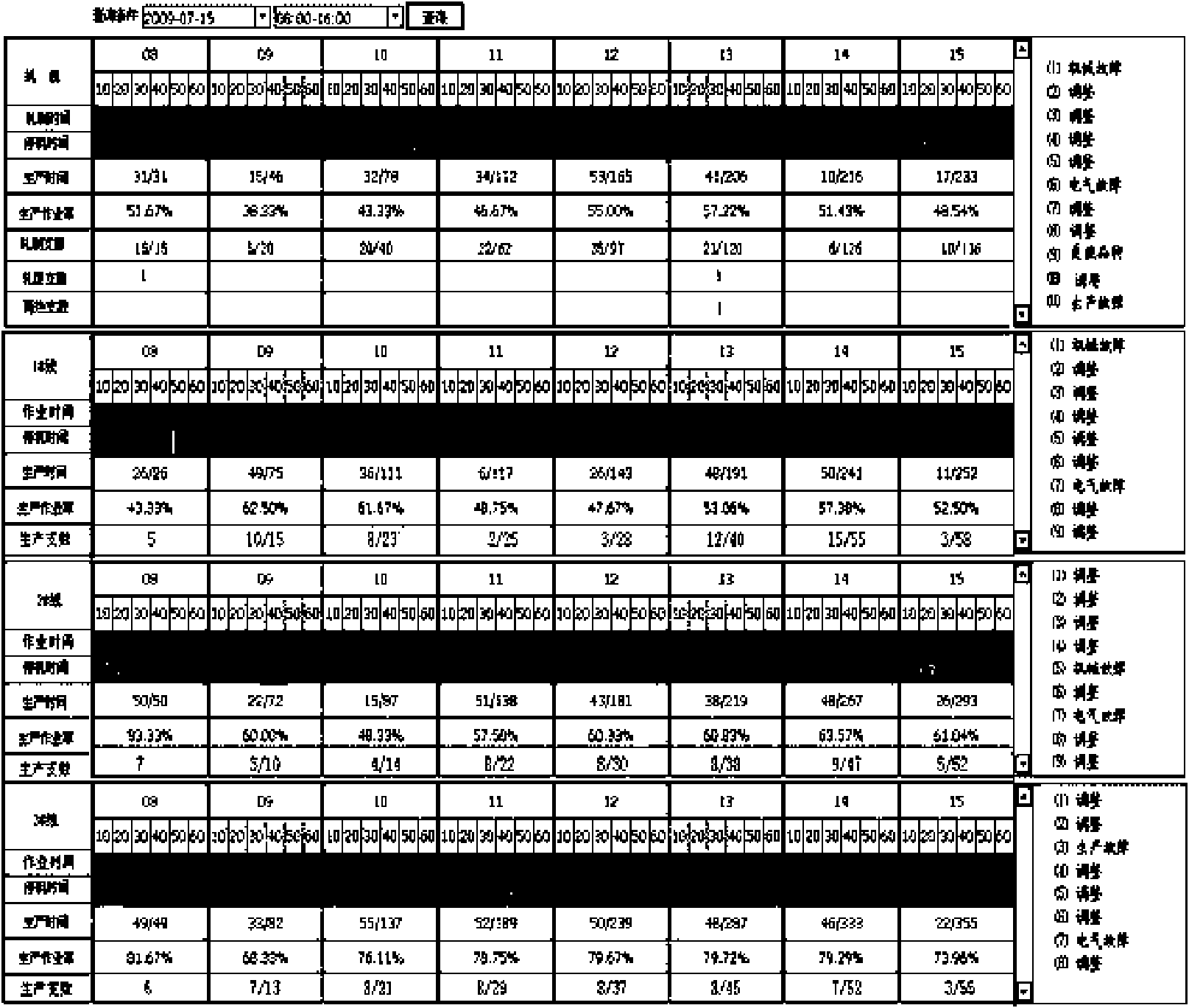

[0021] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

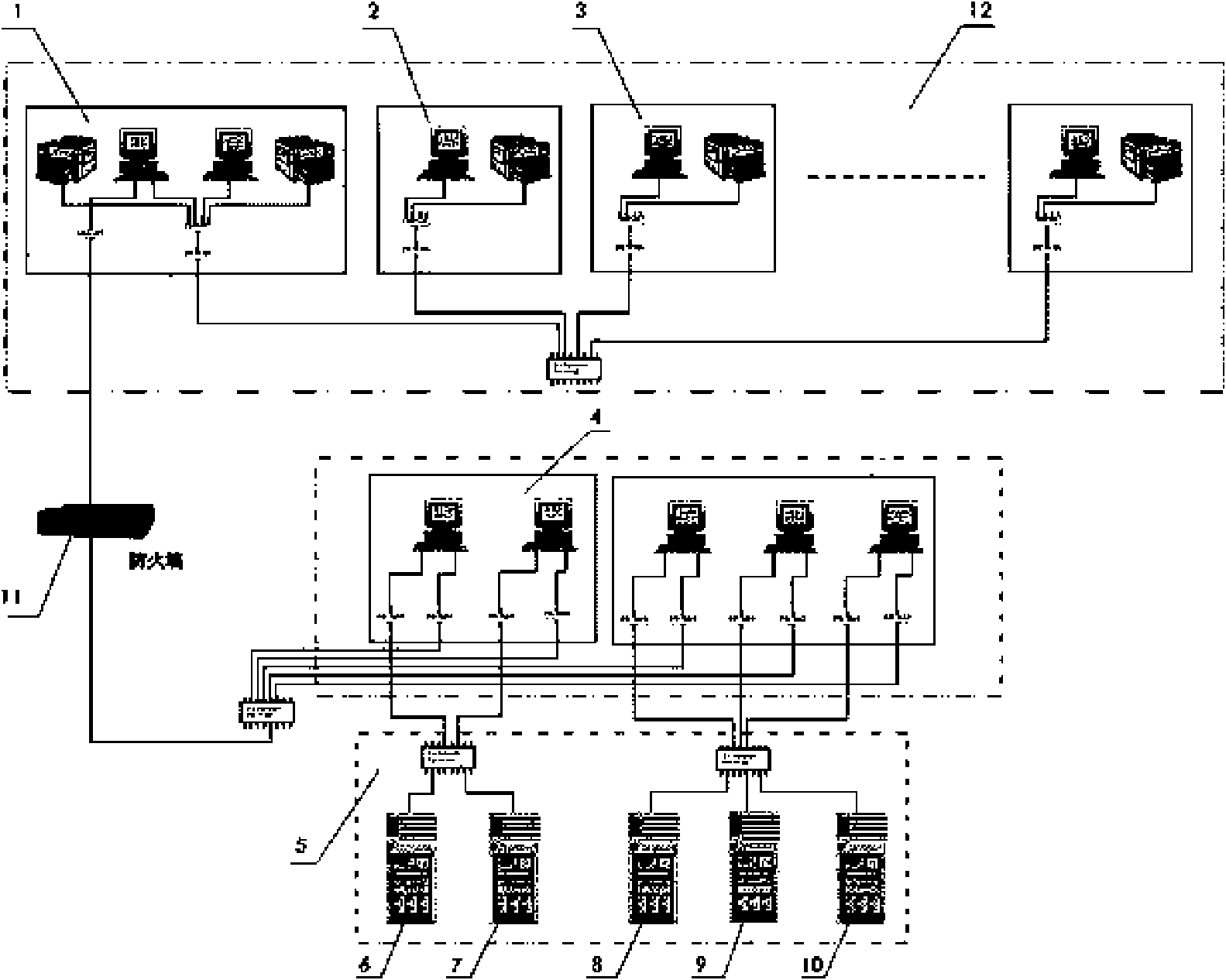

[0022] A hardware structure diagram of a computer network system according to an embodiment of the present invention is as follows: figure 2 shown. The production line equipment running time automatic recording system proposed by the present invention includes: real-time data collection device 1, background management device 2, display terminal 3, production line area L2 system 4 (process control secondary network system LEVEL 2), production line area L1 system 5 ( Basic automation first-level network system LEVEL 1), BD1 rolling mill PLC6, TM rolling mill PLC7, 1# processing line PLC8, 2# processing line PLC9, 3# processing line PLC10, hardware firewall 11, enterprise local area network 12.

[0023] The real-time data collection device 1 is used to collect the real-time data of production line equipment operation sent from the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com