Plate type production line capable of automatically charging and discharging

An automatic loading and unloading, production line technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing and other directions, can solve the problems of poor positioning accuracy, low production efficiency, time-consuming and laborious manual feeding, and reduce production costs. The effect of high positioning accuracy and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

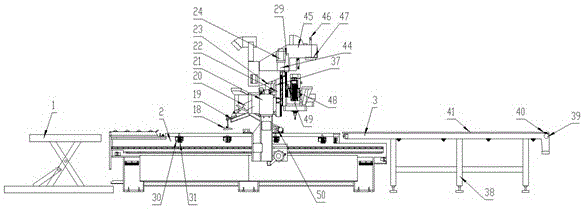

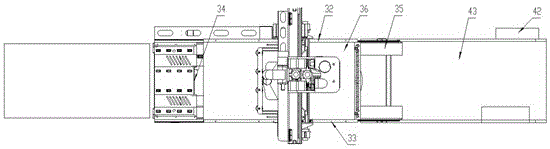

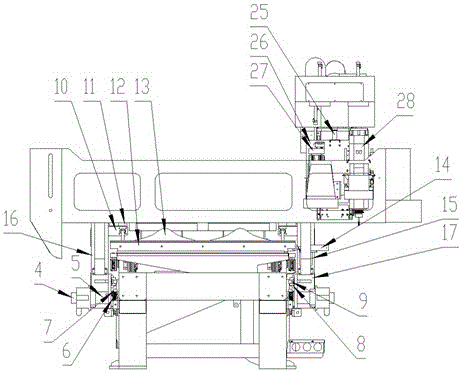

[0023] Attached below figure 1 The present invention is further described:

[0024] like figure 1 , 2 As shown in , 3, the automatic loading and unloading of the panel production line is composed of three parts: the loading table 1, the machine main body 2 and the unloading table 3.

[0025] The feeding table 1 includes a lifting platform arranged on the base. The lower part of the lifting platform is provided with a scissors frame. One end of the hydraulic cylinder is connected to the base and the other end is connected to the scissors frame. The feeding table is provided with a photoelectric switch for detecting the height of the sheet. When the height of the board reaches the height of the photoelectric switch, the lift table stops automatically and raises the photoelectric switch, and there is also a foot switch that can manually adjust the height of the lift table.

[0026] The unloading table 3 is composed of a motor, a reducer 42 , a belt 43 , a material-blocking bak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com