Caterpillar vending machine and automatic vending method

A vending machine and crawler-type technology, applied in the direction of coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., can solve the problem of selling goods Poor adaptability, troublesome replenishment, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0106] Embodiment 1: (in the case of multiple containers)

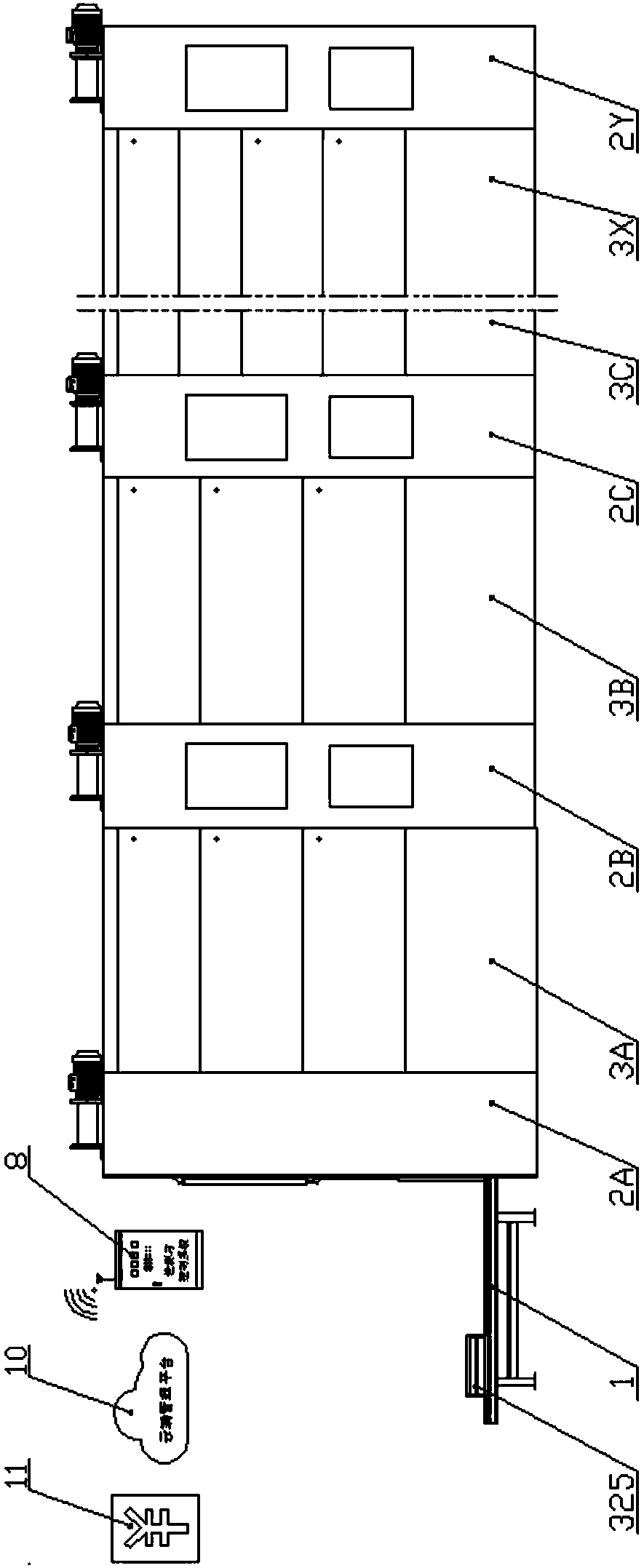

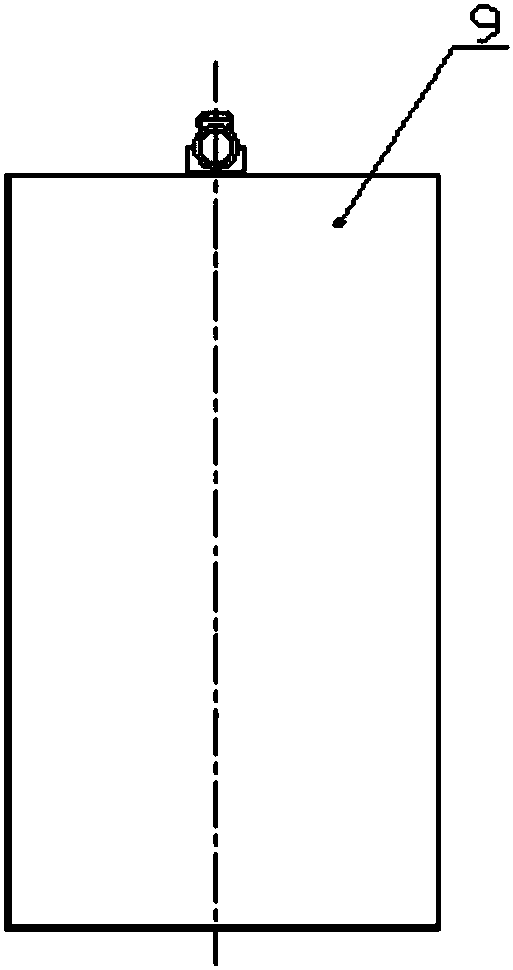

[0107] The present invention relates to a crawler type automatic vending machine such as figure 1 As shown, it includes a replenishment unit 1, a transfer unit 2A, 2B, 2C and ... 2Y, a container unit 3A, 3B, 3C and ... 3X, a detection and control unit 8, a cloud management platform 10, a payment system 11 and a front end Sealing plate 7 and rear end sealing plate 9. Its transfer units 2A, 2B, 2C and ... 2Y and container units 3A, 3B, 3C and ... 3X are aligned and arranged alternately along the feed side to the discharge side, and they are fixedly connected to each other by bolts or buckles , forming a large cabinet, which is the main body of the vending machine, all the transfer units 2A, 2B, 2C and ... 2Y and the container units 3A, 3B, 3C and ... 3X have the same height; the front end sealing plate 7 is installed on the The outer side of the feeding side of a transfer unit 2A is flush with the end face of the tran...

Embodiment approach 2

[0171] Implementation mode 2: (the case of only one container)

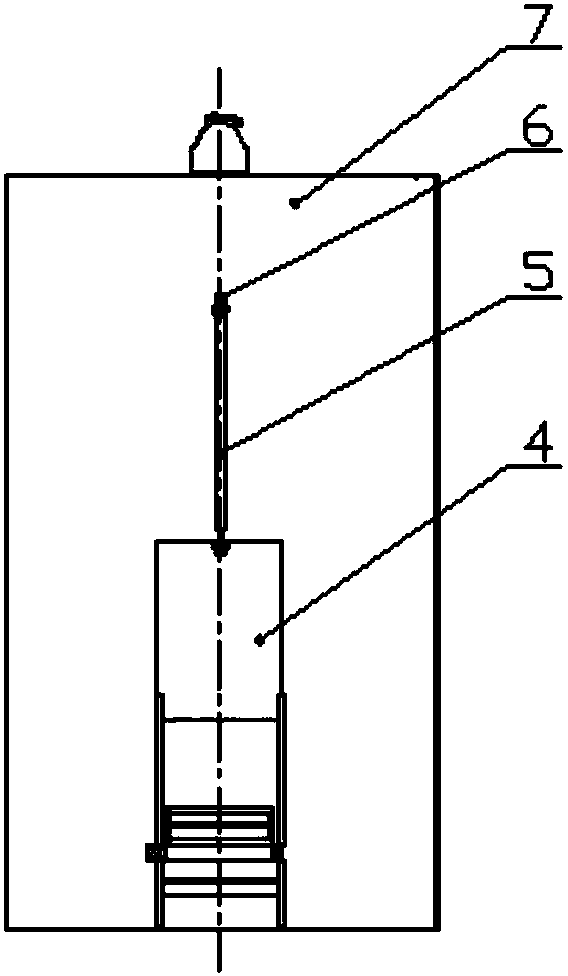

[0172] The present invention relates to a crawler type automatic vending machine such as Figure 11 , Figure 12 and Figure 13 As shown, it includes a replenishment unit 1 , a transfer unit 2 , a container unit 3 , a detection and control unit 8 , a cloud management platform 10 , a payment system 11 , and a front-end sealing plate 7 and a rear-end sealing plate 9 .

[0173] The replenishment unit 1, the transfer unit 2 and the container unit 3 are sequentially connected along the cargo conveying direction, and their relative positions and connections are the same as those of the replenishment unit 1, the first transfer unit 2A and the first container unit in Embodiment 1. The container unit 3A is consistent; the front-end sealing plate 7 is installed on the outside of the feeding side of the transfer unit 2, flush with the end face of the transfer unit 2; an incoming door 4 is arranged on the outside of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com