Small non-pin transformer structure

A leadless, transformer technology, applied in the direction of transformer/inductor core, transformer/inductor parts, transformer/inductor coil/winding/connection, etc., can solve the problem of inability to achieve mechanical processing, uneven magnetic field distribution, Overall performance impact and other issues, to achieve the effect of saving effective space, simplifying wiring requirements, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

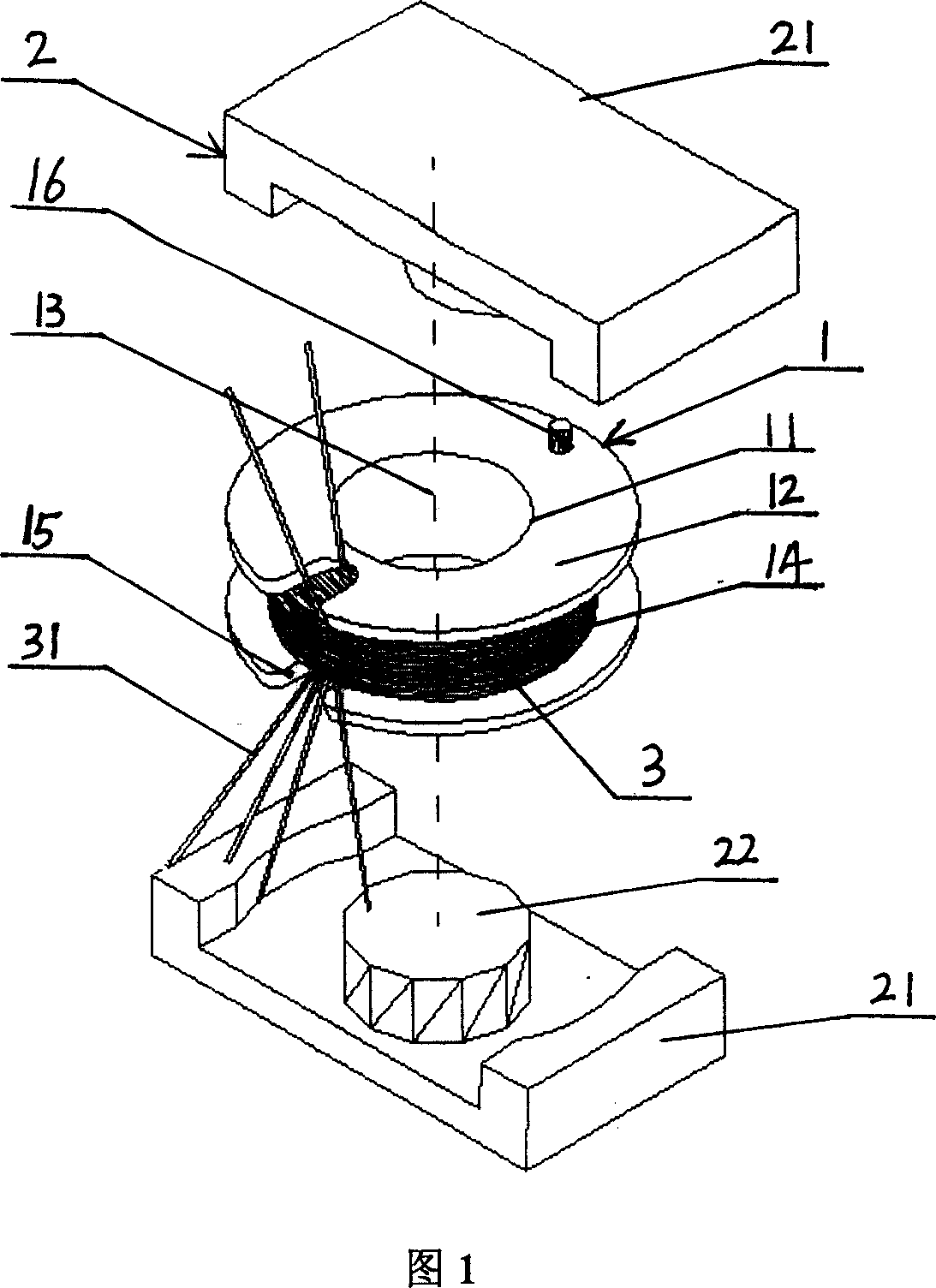

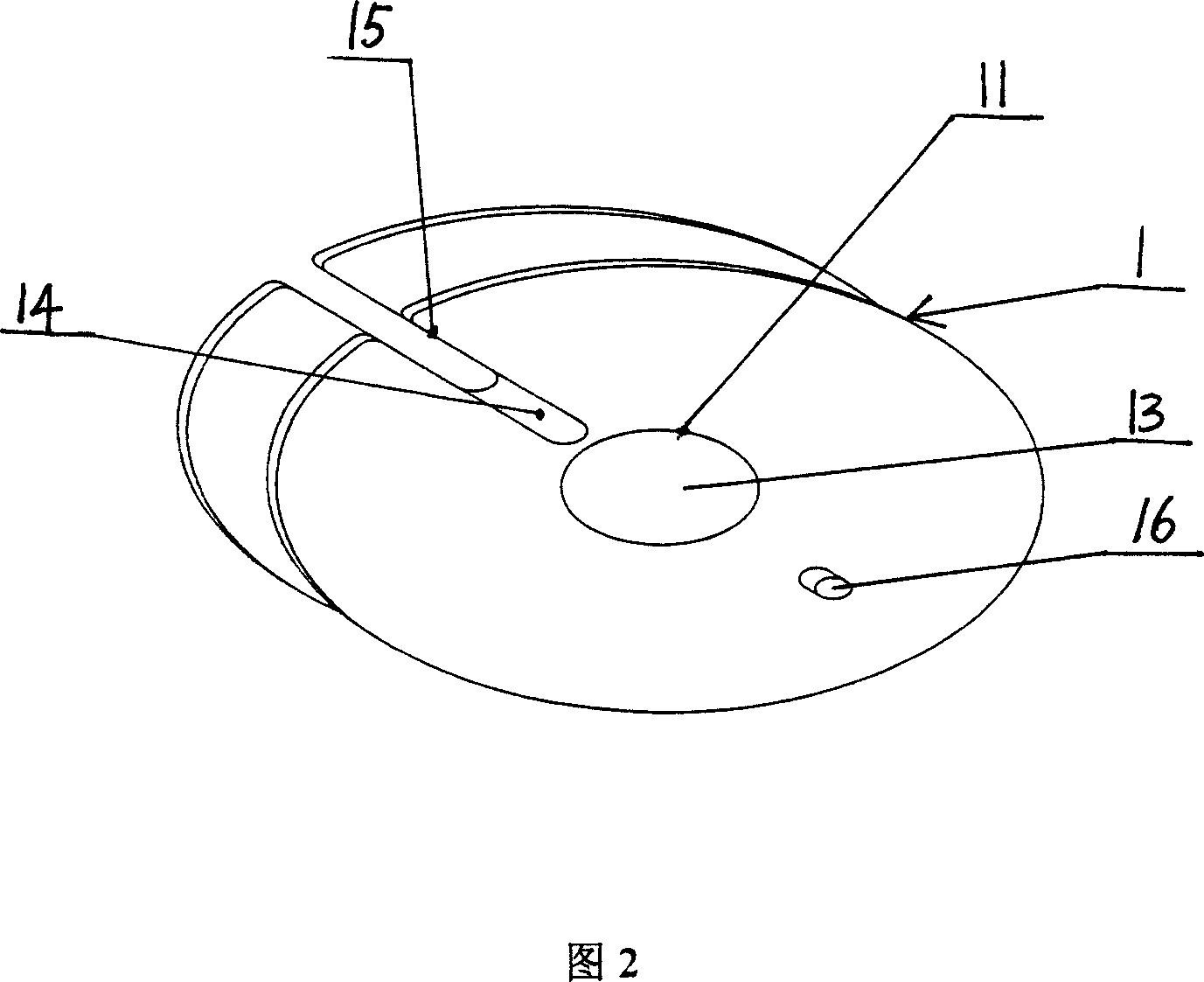

[0017] As shown in Figure 1 and Figure 2, a small PIN-free transformer structure includes a magnetic core, a skeleton, and a winding wire. The skeleton 1 is composed of a bobbin 11 and two ring-shaped end faces 12, and the bobbin 11 has a through shaft hole 13. , two ring-shaped end faces are arranged at both ends of the bobbin and are integrated with the bobbin, and a bobbin groove 14 is formed between the two ring-shaped end faces; the magnetic core 2 is composed of two symmetrical magnetic frames 21, and the magnetic frame is E-shaped. The two magnetic frames face each other, the magnetic core post 22 in the two magnetic frames is placed in the shaft hole 11 of the bobbin, and the skeleton 1 is sandwiched between the two magnetic frames 2, so that the skeleton can rotate around the magnetic core post. The wire 3 is wound in the bobbin groove 14, and the same side of both ends of the skeleton is respectively provided with guide gaps 15 for lead-out wires, and the ends 31 of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com