Vacuum glass laser welding table

A vacuum glass and laser welding technology, which is applied in the field of vacuum glass processing equipment and vacuum glass laser welding platform, can solve the problems of low productivity and small thermal stress, and achieve the effect of overcoming high welding temperature, flexible welding, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

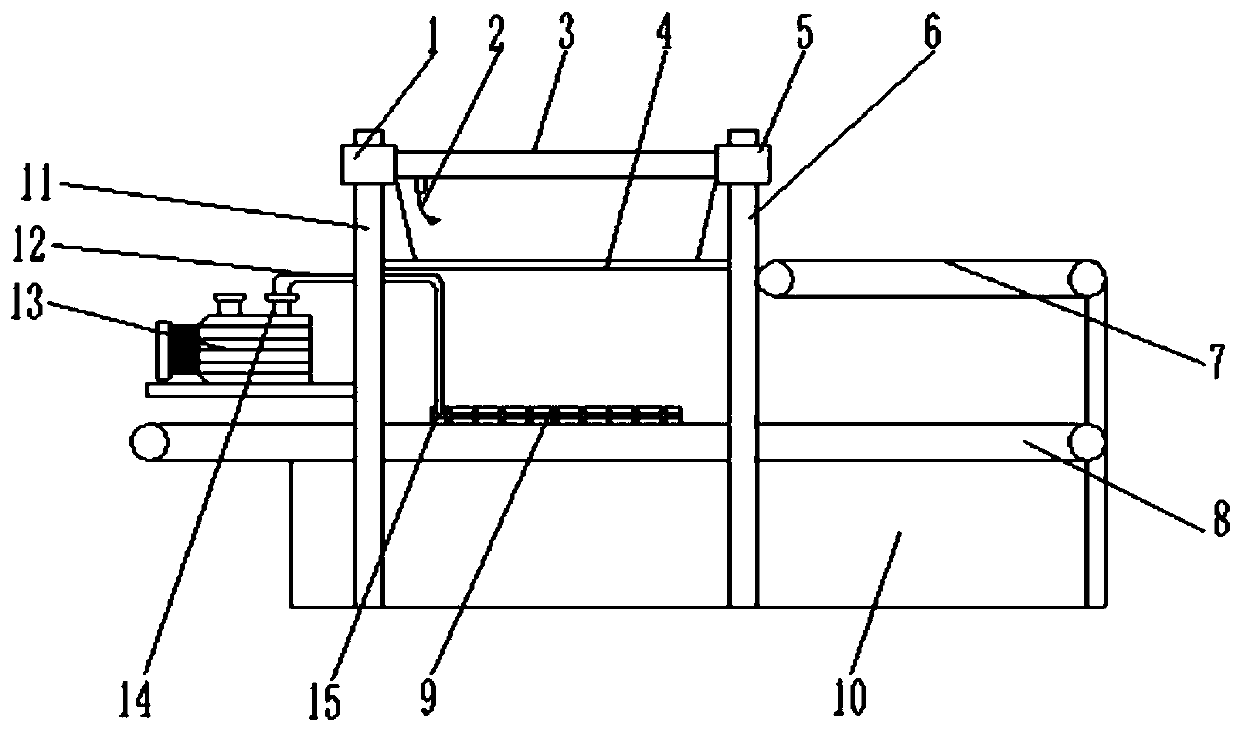

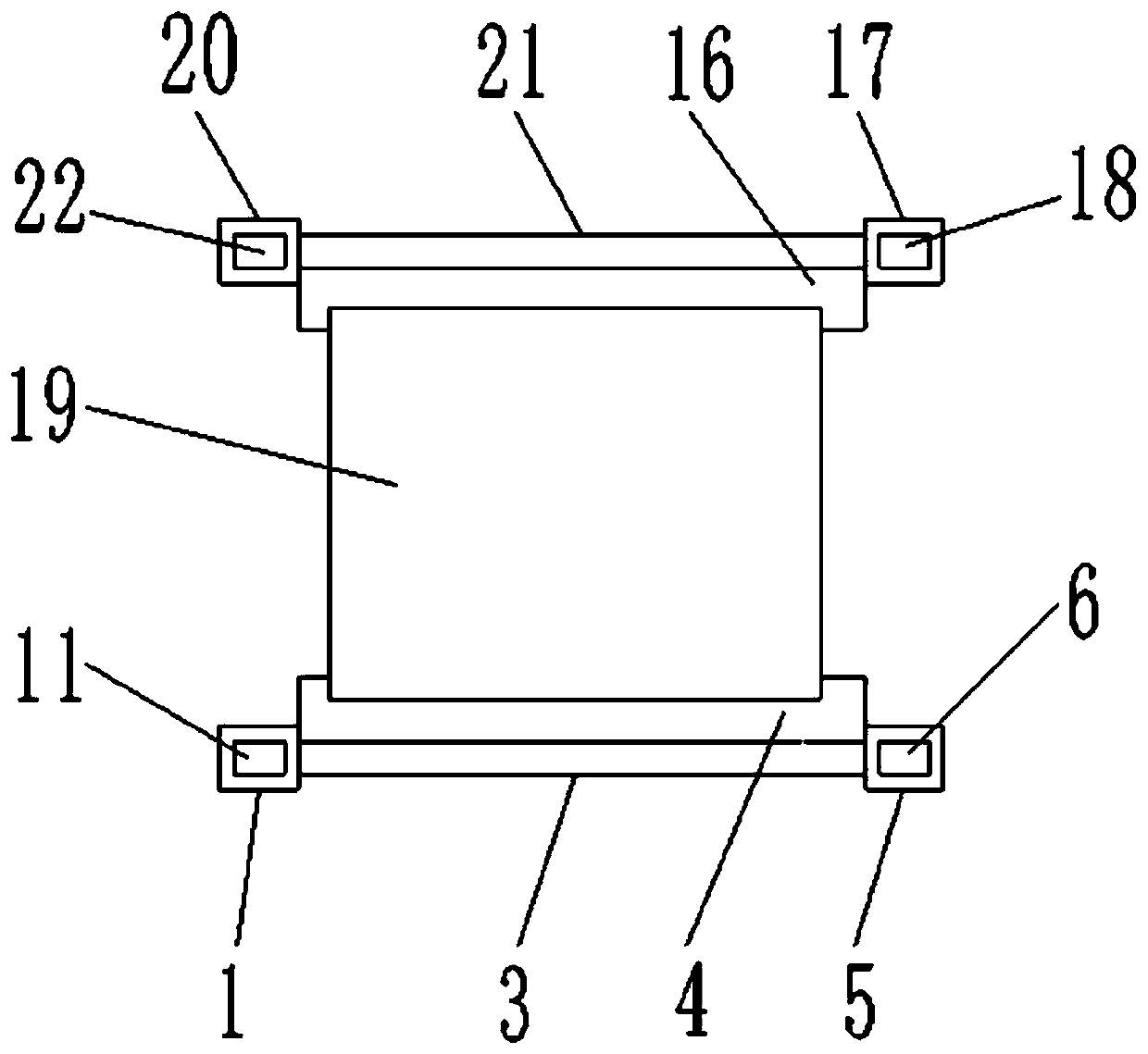

[0013] The present invention will be further described below in conjunction with accompanying drawing:

[0014] Such as Figure 1-2 As shown, a vacuum glass laser welding platform, the workbench 10 is provided with a lower conveyor belt 8, and the front and rear sides of the workbench 10 are respectively provided with a first slide rail 11, a second slide rail 6, a third slide rail 18 and a first slide rail 18. Four slide rails 22, the first slide rail 11 is provided with a first slide block 1, the second slide rail 6 is provided with a second slide block 5, the third slide rail 18 is provided with a third slide block 17, and the fourth slide rail 18 is provided with a third slide block 17. The rail 22 is provided with a fourth slide block 20, a front blanking support 3 is fixedly arranged between the first slide block 1 and the second slide block 6, and a laser welding head 2 is fixedly provided below the front blanking support 3. A front supporting plate 4 is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com