High pressure cyclone double layer gas protective welding gun

A gas shielded welding and high-pressure swirl technology, which is applied in the directions of gas fuel burners, combustion methods, combustion types, etc., can solve the problems of unsatisfactory arc characteristics, weak anti-interference ability, and high gas prices, and improve the maintenance of axial laminar flow. performance, enhanced anti-interference ability, flexible welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

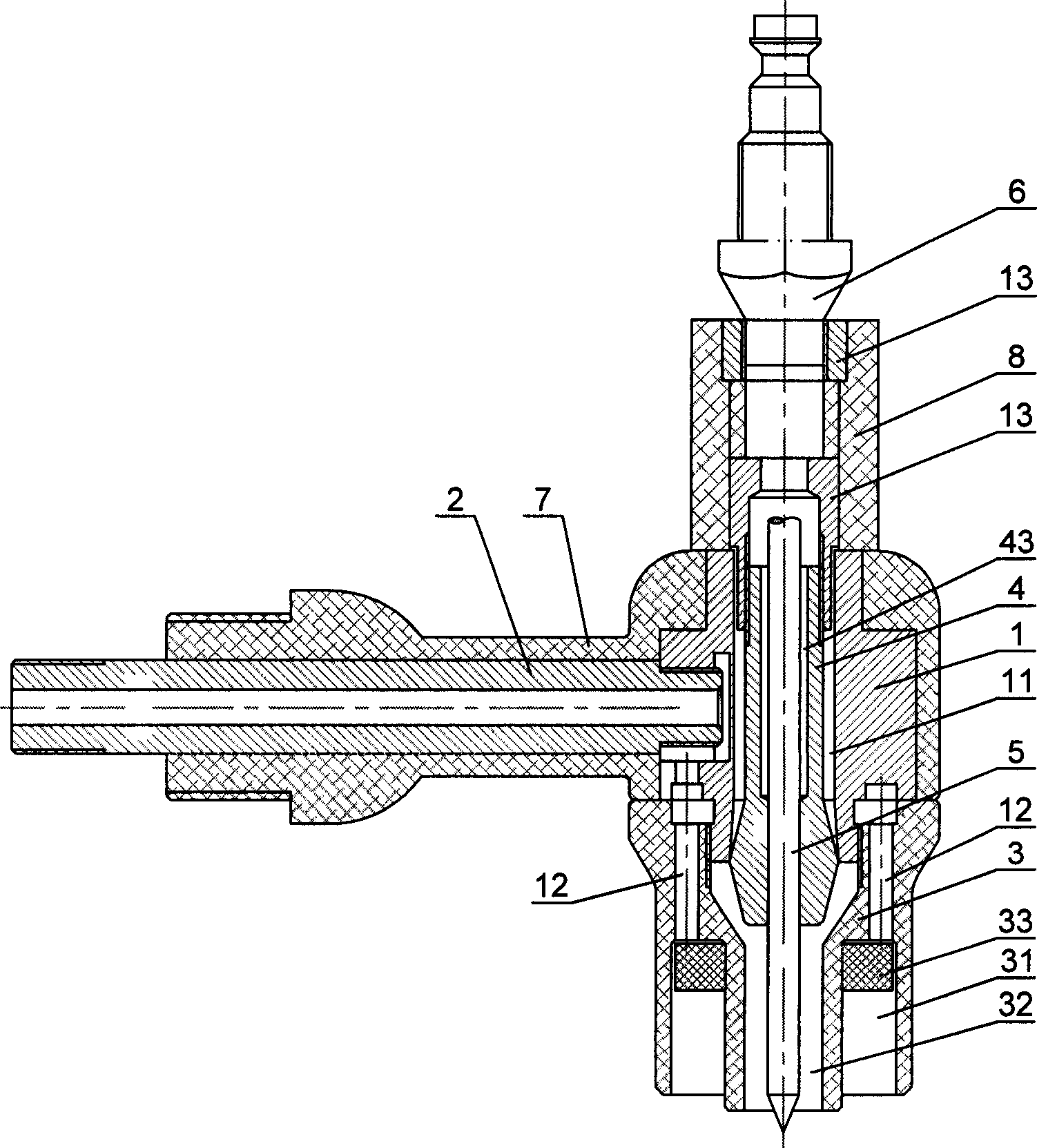

[0014] first as figure 1 Shown, be a kind of high-pressure swirl double-layer gas shielded torch provided by the present invention, it mainly includes:

[0015] A main body 1, the center of which is provided with a tungsten pole holder cavity 11;

[0016] An outer air intake duct 2, which is connected and arranged on the side wall of the body 1;

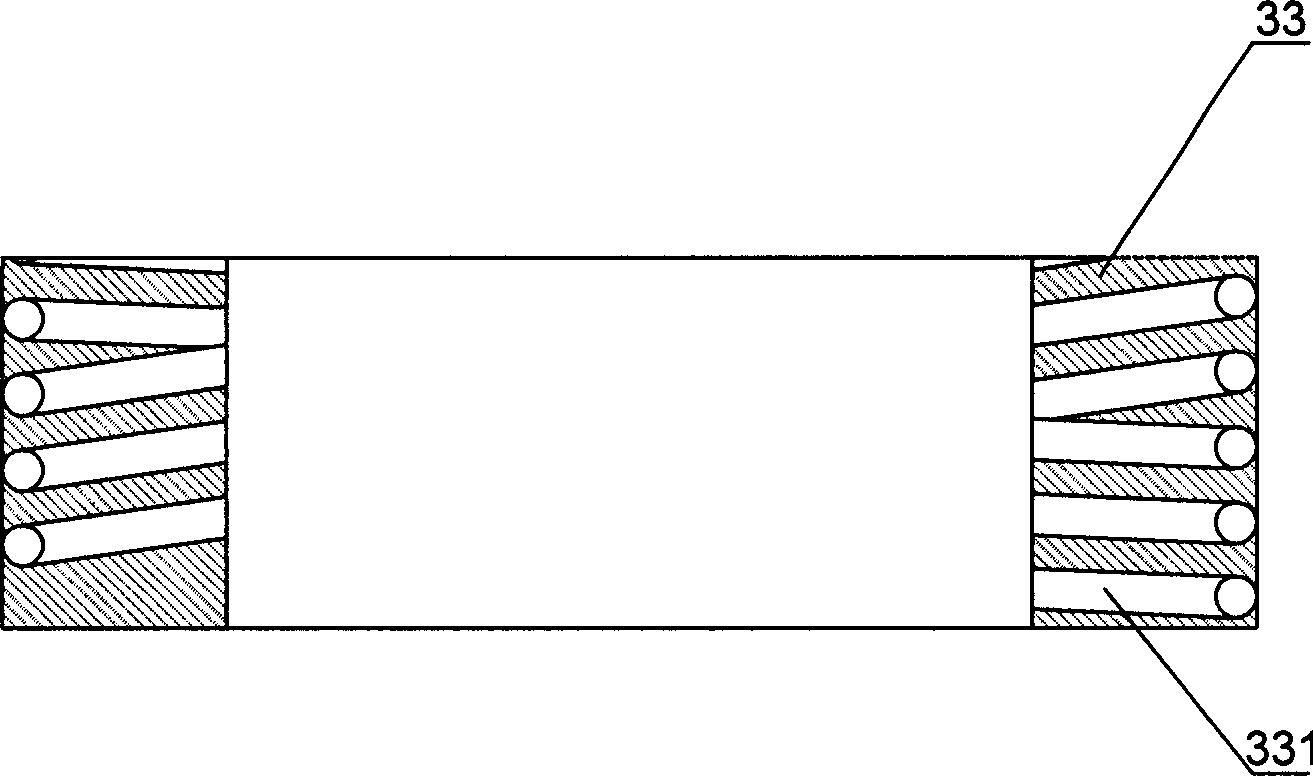

[0017] A double-layer nozzle 3, which is connected to the bottom of the body 1, the double-layer nozzle 3 includes an outer layer nozzle 31 and an inner layer nozzle 32 sleeved in the outer layer nozzle, and the outer layer nozzle 31 is provided with a swirling body 33; in addition, the body 1 is provided with an outer layer gas pipeline 12 connecting the outer layer air intake conduit 2 and the outer layer nozzle 31;

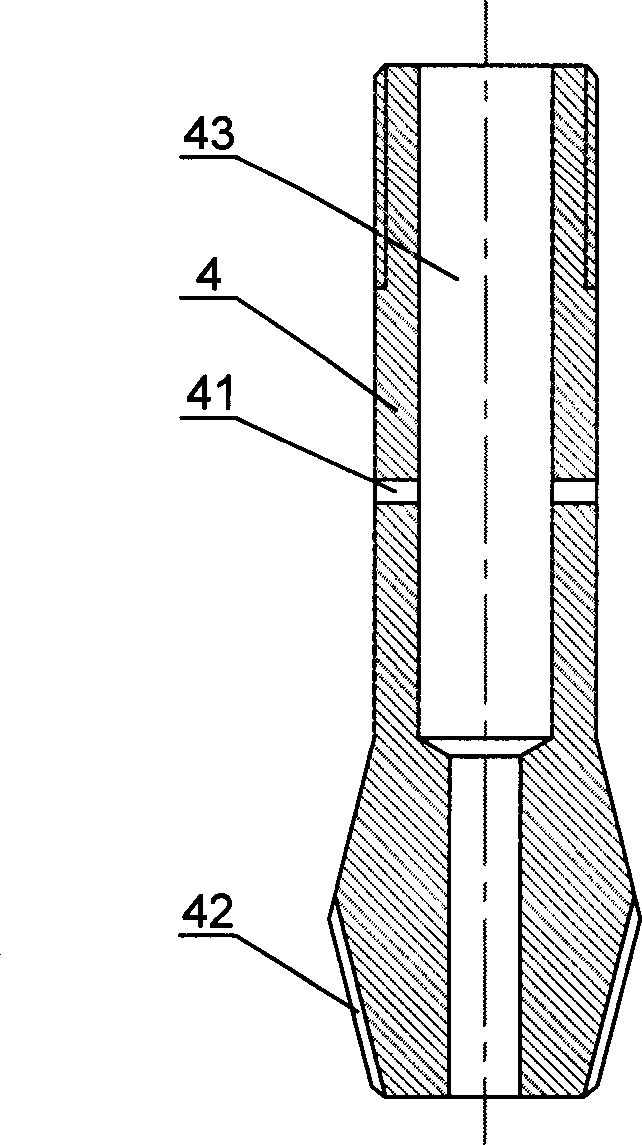

[0018] A tungsten pole clamp 4, which is arranged in the tungsten pole clamp housing cavity 11 of the body 1, and the lower part of the tungsten pole clamp 4 is located at the upper part of the inner layer nozzle 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com