New cross-convective flue gas purification absorption tower

A technology of flue gas purification and adsorption tower, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve the problems of secondary pollution of the surrounding environment, high water consumption, and no performance, etc., and reduce construction and operation costs , large adsorption sulfur capacity and reduced damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following, the present invention will be further described in detail with reference to the drawings and specific embodiments.

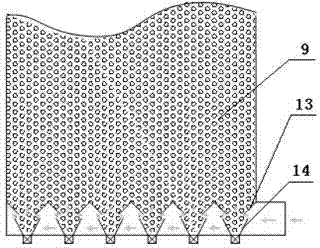

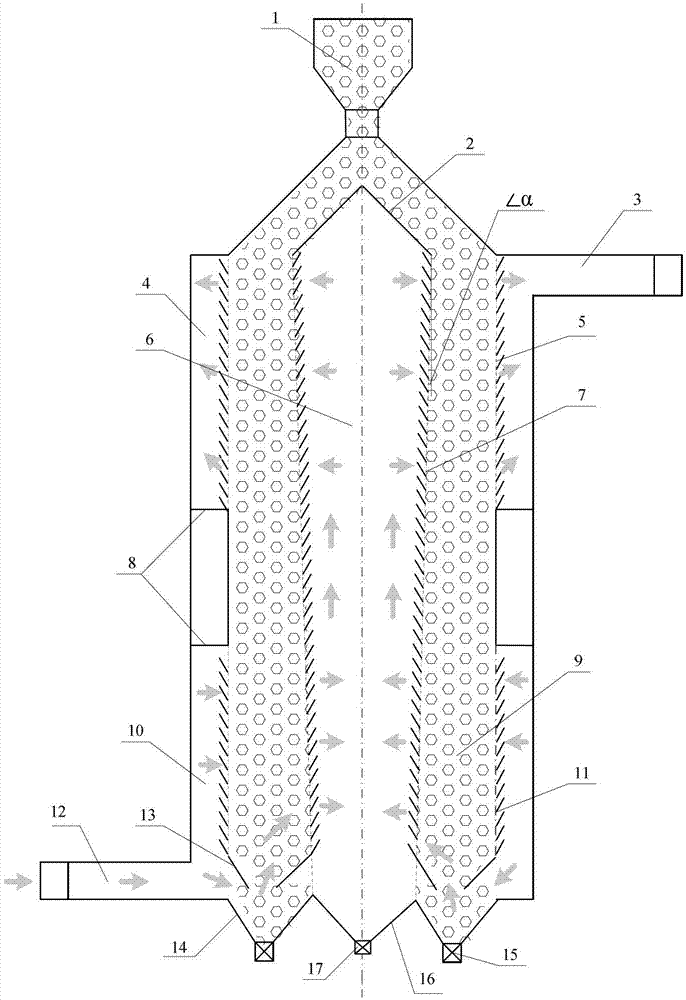

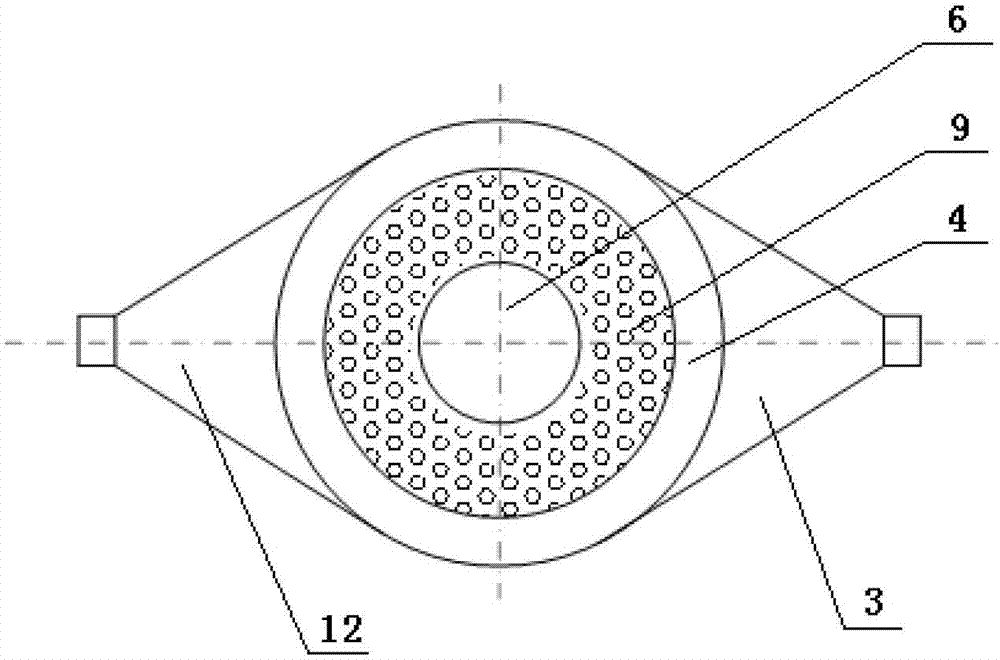

[0026] Such as figure 1 with figure 2 As shown, a novel cross-convection flue gas purification adsorption tower of the present invention includes a feed hopper 1, a distributor 2 is provided at the lower part of the feed hopper 1, and an activated coke bed 9 with an annular cross section is provided at the lower part of the distributor 2, and activated coke The inside of the bed 9 is an intermediate flue gas collecting chamber 6, and the outside is separated by a double-layer annular partition 8 into an upper clean flue gas collecting chamber 4 and a lower original flue gas distribution chamber 10, the activated coke bed 9 It is connected with the intermediate flue gas collecting chamber 6 through the intermediate flue gas collecting chamber grid 7, and the activated coke bed 9 and the clean flue gas collecting chamber 4 are connected throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com