A plc-based continuous rolling transmission monitoring system and its monitoring method

A technology of monitoring system and monitoring unit, which is applied in the field of steel rolling in steel mills, can solve the problems of reducing the PLC module CPU control module of the main station, etc., and achieve the effects of improving scalability, convenient viewing and unified management, and improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

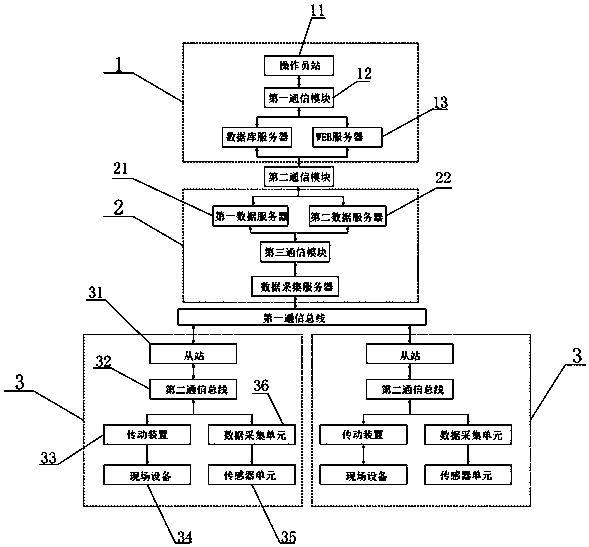

[0039] Such as figure 1 As shown, the present invention includes an upper monitoring unit 1, an intermediate network unit 2 and a plurality of on-site monitoring units 3; the upper monitoring unit 1 communicates with the intermediate network unit 2 through the second communication module, and the intermediate network unit 2 communicates through the first communication The bus communicates with the on-site monitoring unit 3, and the number of on-site monitoring units 3 in this embodiment is two.

[0040] The upper monitoring unit 1 includes an operator station 11, a database server and a WEB server 13. The operator station 11 adopts an industrial computer, and monitoring configuration software is installed in the industrial computer. The industrial computer accesses the data server and the WEB server 13 through the first communication module 12 , can read the data in the data server and the WEB server 13, and the first communication module 12 adopts a switch.

[0041] The inte...

Embodiment 2

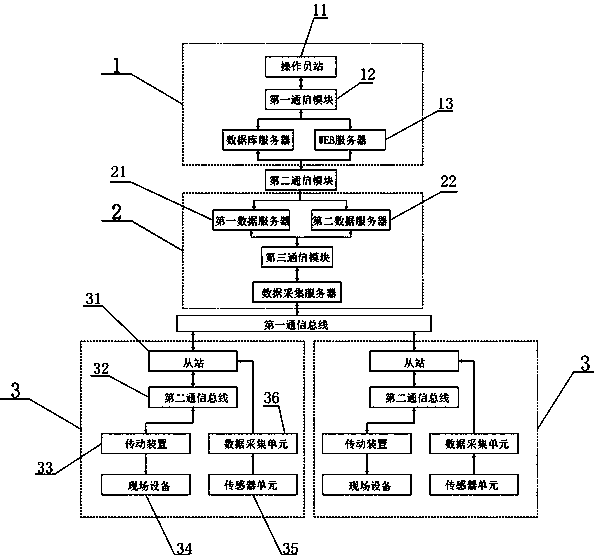

[0058] The difference between this embodiment and embodiment 1 is that, as figure 2 As shown, the data acquisition unit 36 communicates directly with the slave station 31, the data acquisition unit 36 has an RS485 communication interface, and the data acquisition unit 36 communicates with the slave station 31 through the RS485 bus.

Embodiment 3

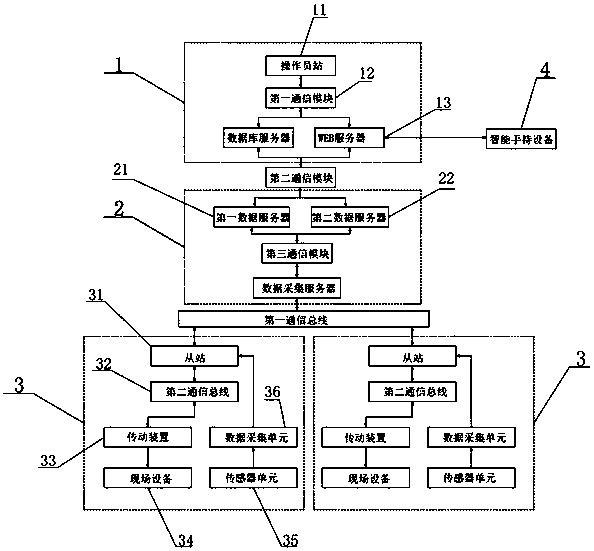

[0060] The difference between this embodiment and embodiment 2 is that, as image 3 As shown, the present invention also includes a smart handheld device 4, the smart handheld device 4 adopts a smart phone, and the smart phone is installed with an APP developed for this system, and accesses the WEB server 13 through the APP access Internet network, and the smart handheld device 4 can be used anytime, anywhere access the data in the WEB server 13, and keep abreast of the operating conditions of the system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com