Welding fixture and method of brazing large-scale aluminum alloy curved skin and ribbed skeleton structure

A brazing method and skeleton structure technology, applied in the direction of welding/welding/cutting items, welding equipment, auxiliary welding equipment, etc., can solve problems such as unsuitable components and deformation, and achieve improved fluidity, high efficiency, and high welding accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

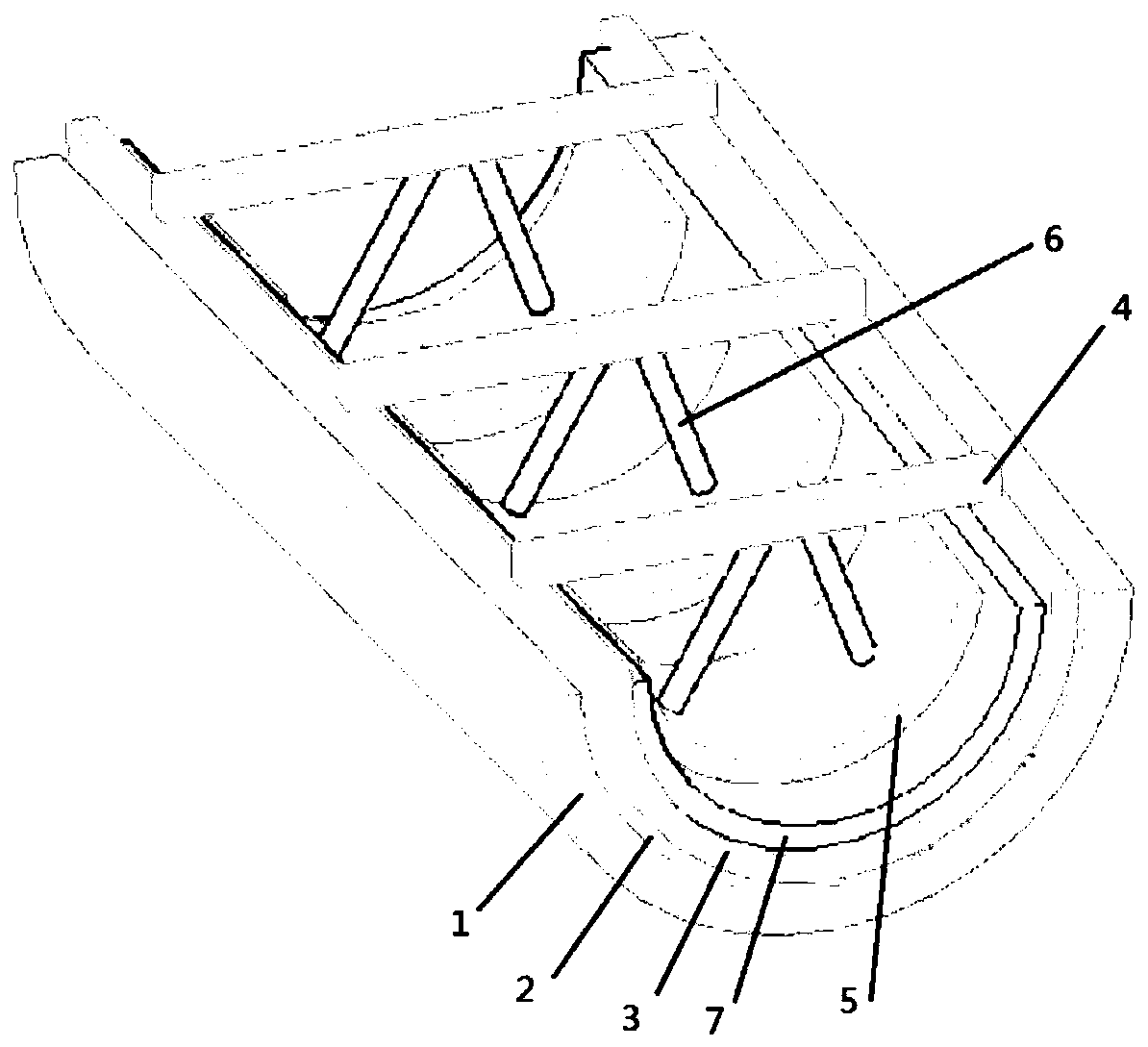

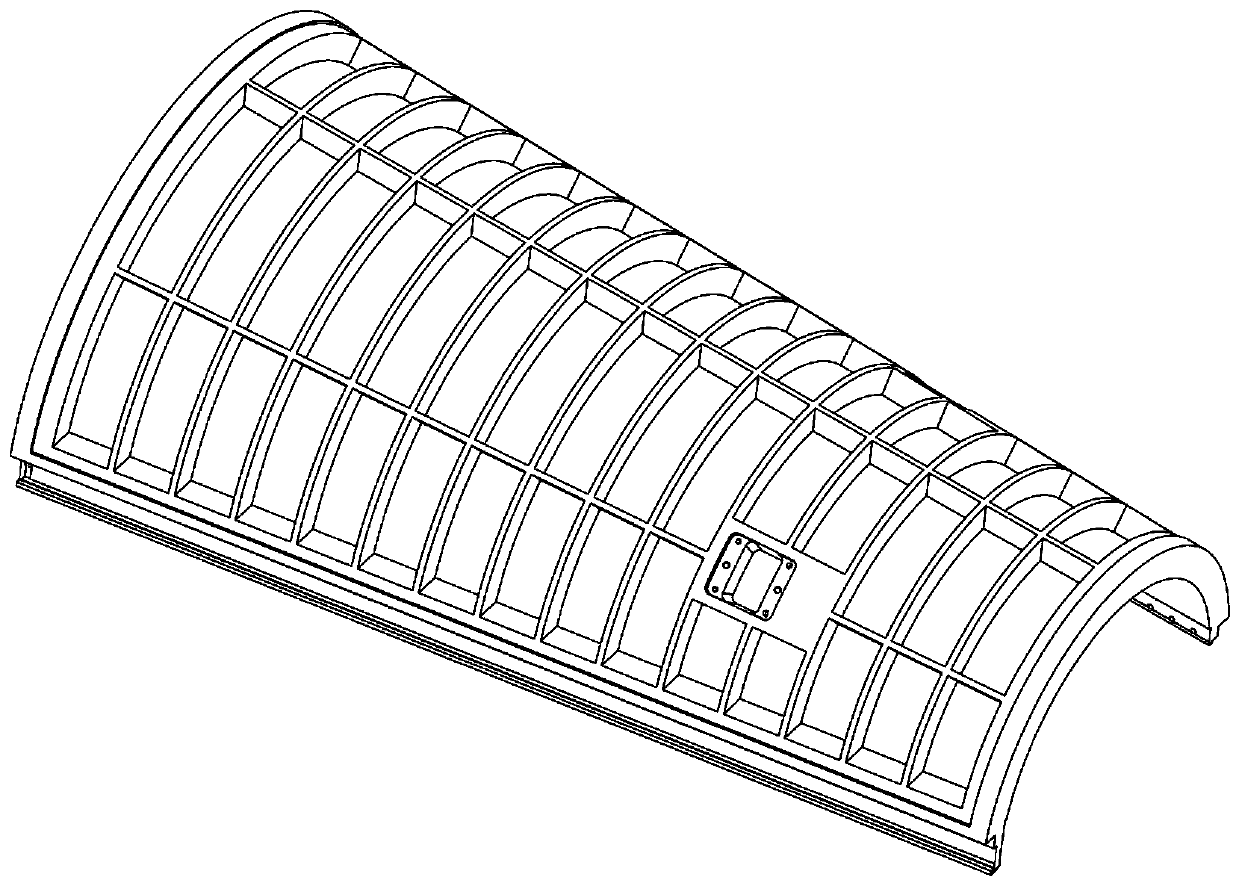

[0027] Specific embodiment 1: In this embodiment, a welding jig is a semi-circular pipe structure, and the welding jig includes an insulation layer 1, a heating blanket 2, a limit mold 3, a mold pull rod 4, a pressure gasket 5 and a pressure screw 6; A heating blanket 2 is attached to the inner surface of the insulation layer 1, and the heating blanket 2 is covered on the outer surface of the limiting mold 3; on the upper edge of the limiting mold 3, a plurality of mold tie rods 4 are horizontally placed at intervals in parallel, and each mold tie rod 4 Two pressure screw rods 6 are threadedly connected to the bottom, and the lower ends of the two pressure screw rods 6 are fixedly connected to the pressure pads 5 . Wherein the pressure gasket 5 is attached to the workpiece 7 to be welded on the limit mold 3 .

[0028] The materials of the press screw 6 and the press pad 5 in this embodiment are stainless steel, and the press pad 5 is directly placed on the surface of the workp...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment differs from Embodiment 1 in that the insulation layer is made of asbestos. Others are the same as the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: In this implementation mode, the method of brazing a large-size aluminum alloy curved surface skin and a ribbed skeleton structure with a welding fixture is carried out according to the following steps:

[0031] 1. Perform pre-weld heat treatment on the aluminum alloy skin and ribbed frame;

[0032] 2. Grinding and cleaning the heat-treated aluminum alloy skin and ribbed frame before welding;

[0033] 3. Mark the position to be welded on the aluminum alloy skin after heat treatment;

[0034] 4. Coating the aluminum alloy skin and the skeleton with ribs separately: place the aluminum alloy skin on the heating table to heat, and after reaching the preset temperature, apply the brazing material in step 3 to determine place the ribbed frame on the heating table to heat, and after reaching the preset temperature, coat the brazing material on the surface of the vertical rib of the ribbed frame; during the solder coating process, use ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com