Container top reinforced plate automatic welding device with three dimensional weld recognition

An automatic welding and reinforcing plate technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the welding wire cannot be aligned with the weld seam, and achieve the effect of convenient welding sequence, flexible welding and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

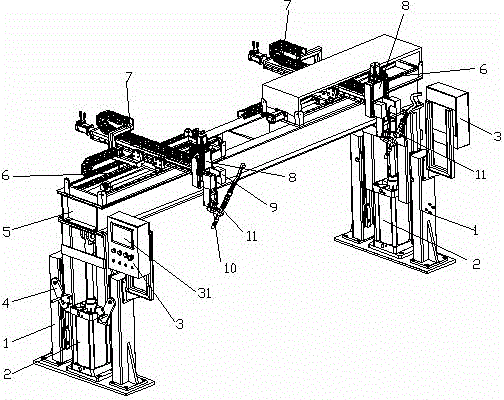

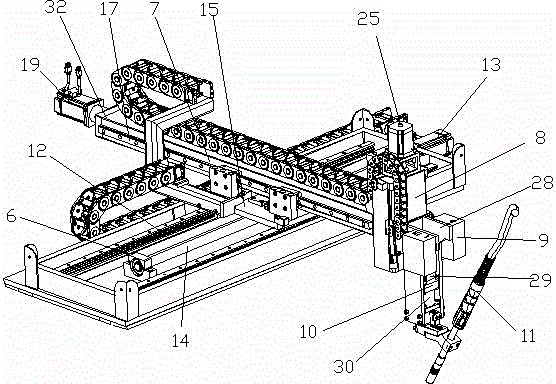

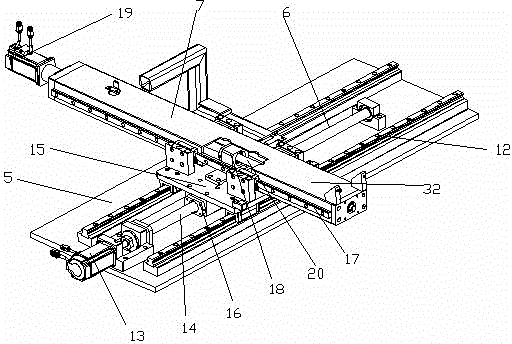

[0025] Such as Figure 1-4 The shown automatic welding equipment for container roof reinforcement plate with three-dimensional weld recognition includes two lifting frames 1, wherein each lifting frame 1 is equipped with a lifting cylinder 2 and a control box 3, and a touch screen is installed on the control box 3 31. A limit mechanism 4 is installed between the lifting frame 1 and the lifting cylinder 2. A crossbeam 5 is mounted on the lifting cylinder 2. Two X-axis traveling mechanisms 6 are installed on the crossbeam 5. Each X-axis A Y-axis traveling mechanism 7 is installed on the traveling mechanism 6, a Z-axis traveling mechanism 8 is installed on the Y-axis traveling mechanism 7, an R-axis rotating mechanism 10 is installed on the Z-axis traveling mechanism 8, and the R-axis rotating mechanism Laser displacement sensor 9 and straight handle welding torch 11 are respectively installed on 10. Metal covers are respectively installed on the X-axis traveling mechanism and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com