Welding positioning clamp

A welding positioning and fixture technology, used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. The device has the advantages of simple structure and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

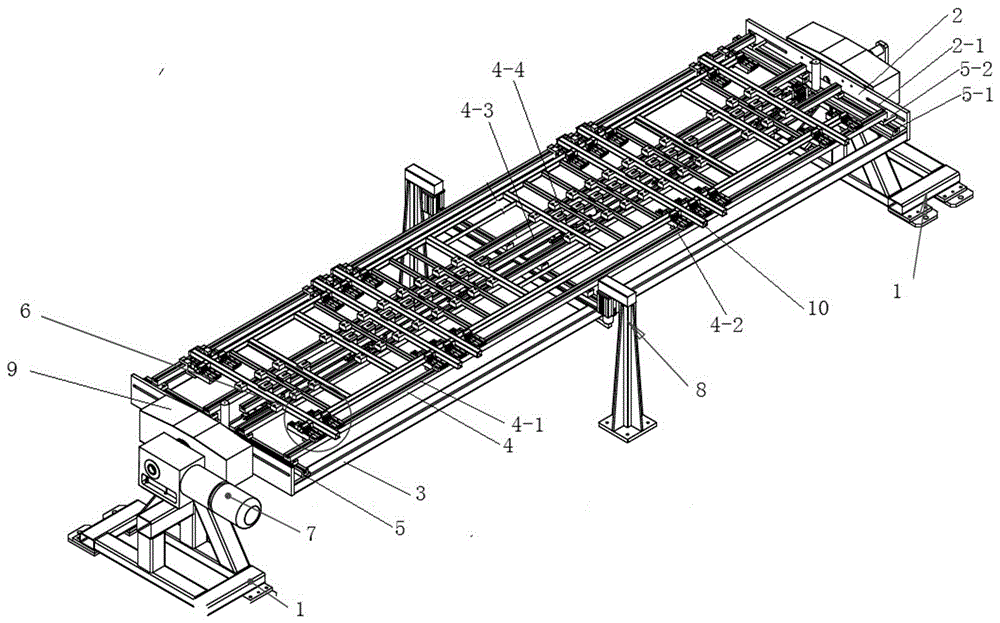

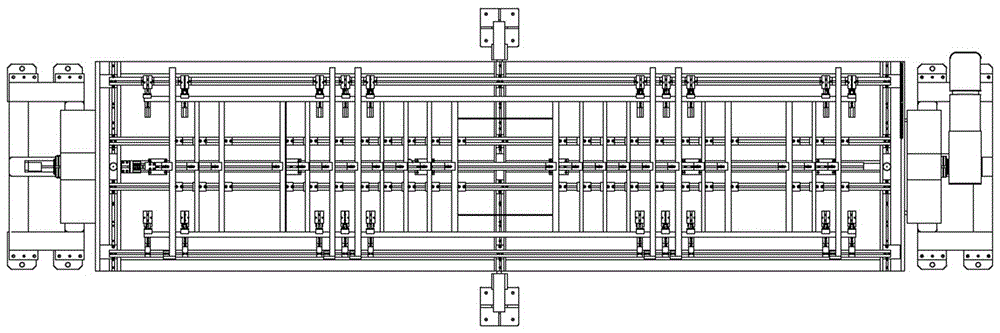

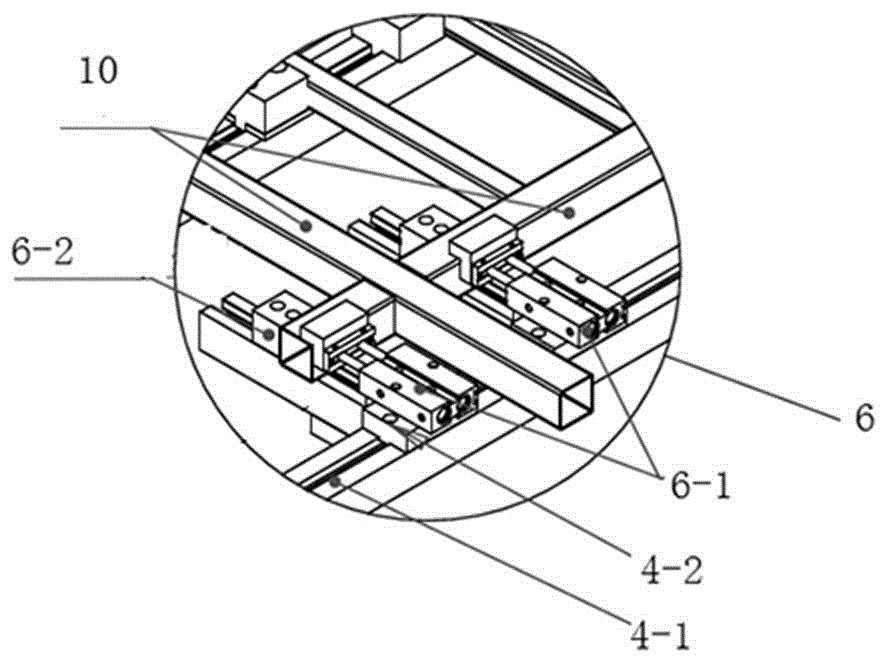

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] like Figure 1~Figure 3 As shown, the present invention provides a welding positioning fixture, including a pair of first support frames 1 fixedly arranged on the ground, and a fixed clamp body arranged between the first support frames 1;

[0024] The first support frame 1 is a trapezoidal structure, the bottom end of the first support frame 1 is fixedly installed on the ground by bolts, and a motor 7 for driving the fixed clamp body to rotate is installed on the upper end of the first support frame 1, and the output of the motor 7 The shaft is connected with the baffle plate 2 through the connector 9. When the motor 7 is working, the output shaft drives the baffle plate to rotate, and then drives the longitudinal guide groove 4, the pressing device 6 and the workpiece 10 to rotate.

[0025] Further, the fixing clip specifically includes: a baffle 2 installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com