Friction-stir welding device

A welding device and friction-stir technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of clumsiness, unfavorable movement, narrow processing range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

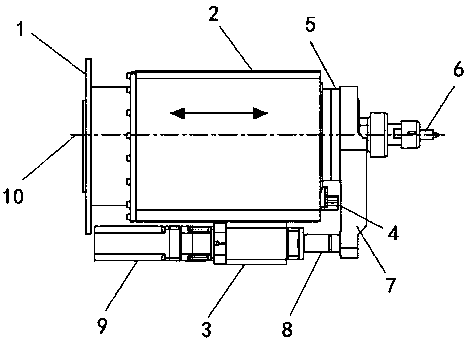

[0016] figure 1 They are a friction stir welding device according to an embodiment of the present invention. The friction stir welding device includes a flange seat 1 for connecting third-party equipment, a main box 2 connected to the flange seat 1, and a ball screw pair. 3. The guide rail slider 4 and the electric spindle 5 arranged on the main machine box 2, the stirring tool 6 bolted on the electric spindle 5, the limit plate 7 which is relatively static with the electric spindle 5, and the constant pressure The sensor 8, the A-axis connected with the ball screw pair 3 drives the servo motor 9, the guide rail slider 4 serves as the sliding support of the electric spindle 5 along the A-axis, wherein the constant pressure sensor 8 is used to obtain the When the shaft shoulder end surface of the stirring tool 6 touches the surface of the part to be welded, that is, when the stirring tool 6 is idling to plunge into the real-time pressure feedback value of the part to be welded,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com