Fixing mechanism for fan blade welding device

A technology of welding equipment and fixing mechanism, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. It can solve the problems of inaccurate welding position, affecting the use of fans, and the inability to realize unified production standardization, etc., and achieve accurate welding position , Welding flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

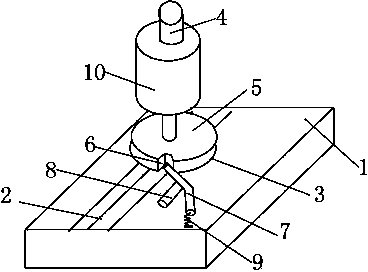

[0009] Combine below figure 1 Specific description embodiment:

[0010] A fixing mechanism for fan blade welding equipment, characterized in that the fixing mechanism of the fan blade welding equipment includes a base 1, a chute 2 is opened in the middle of the base 1, and a chute 2 is provided on the base 1 Platform 3, the platform 3 can slide in the chute 2, the platform 3 is provided with a column 4, the lower part of the column 4 is connected with a disc 5, the side of the disc 5 Four card slots 6 are provided, and a card bar 7 is hinged on the platform 3, and a pull bar 8 is provided on the side of the card bar 7, and one end of the card bar 7 can be clamped in the card slot 6. , the other end of the clip 7 is connected with a spring 9, and the spring 9 is fixed on the platform 3; the middle of the column 4 is provided with a fan positioning seat 10, and the fan positioning seat 10 is connected with the disc 5 phase fixed.

[0011] During specific use, the fan main bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com